External control construction method of super high-rise building core tube shaft net

A construction method and core tube technology, which are used in construction, building construction, and construction material processing to achieve good economic and social benefits, ensure construction quality, and avoid deviations in measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

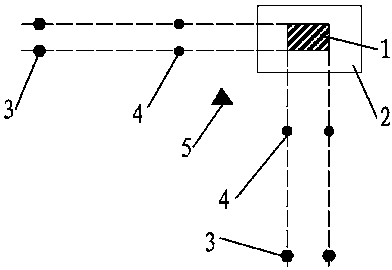

[0014] Such as figure 1 As indicated, first, based on the design basis control points provided by the owner, a control network composed of several control points is set up on the site and outside the ground area not affected by construction;

[0015] The control network formed by control points 4 inside the site is the first-level control network, and the peripheral control network formed by control points 3 outside the site is the secondary control network. The basis for the establishment and review of the control network;

[0016] The measuring instruments adopt total station, laser plumb instrument, laser theodolite, automatic leveling instrument, and the communication between measuring personnel adopts walkie-talkie;

[0017] The control network of the core tube is composed of the control network of the outer wall and the control network of the inner wall. The control network of the outer wall is directly projected by the control points around the building with measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com