Cleaner for steel wire ring accumulative fibers of spinning machine

A cleaner and traveler technology, which is applied in textiles and papermaking, can solve the problems of reducing the labor intensity of car operators and the accumulation of traveler flowers, and achieve the effects of increasing spun yarn production, ensuring quality, and reducing spun yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

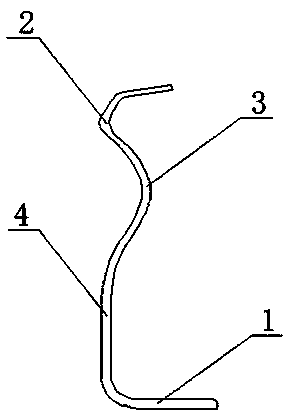

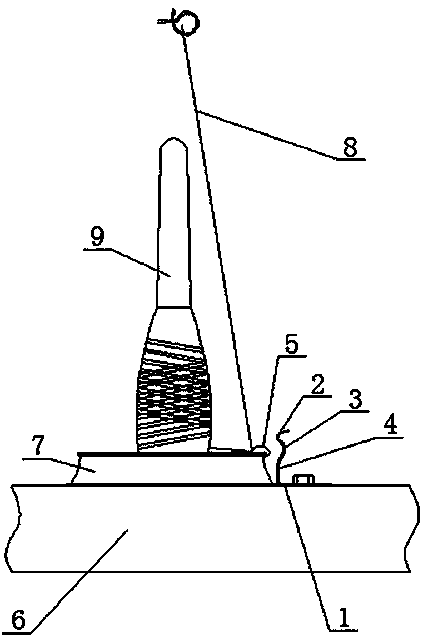

[0015] combine figure 1 , figure 2 It can be seen that the traveler flower cleaner 1 of the spinning machine of the present invention is an arc-shaped cleaner with the upper and lower parts protruding and the middle recessed, and the cleaner upper convex part 2 and the cleaner middle groove 3 are respectively provided from top to bottom , The lower convex part 4 of the cleaner. The groove 3 in the middle part of the cleaner is designed as an arc surface recessed inward by 1 mm, so that the distance between the ring traveler cleaner 1 of the spinning frame and the traveler 5 is shortened by 1 mm. The lower end of the traveler flower cleaner 1 of the spinning machine is fixed on the ring plate 6, the ring 7 is matched with the traveler 5, the yarn 8 is wound on the bobbin 9 through the traveler 5, and the traveler 5 pairs with 8 yarns to winding and twisting.

[0016] The working principle of the present invention is as follows: the bobbin 9 drives the yarn 8 through the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com