A method for isolating toxin protein from white jellyfish tentacles

A technology of white jellyfish and toxin protein, which is applied in the field of separation of toxin proteins caused by increased vascular permeability, can solve the problems of unfavorable separation and purification of impurity proteins, unstable and easy degradation of toxins, and difficulty in toxin collection, and achieves a beneficial effect on toxins. The effect of maintaining activity, being beneficial to separation and purification, and improving the purity of toxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

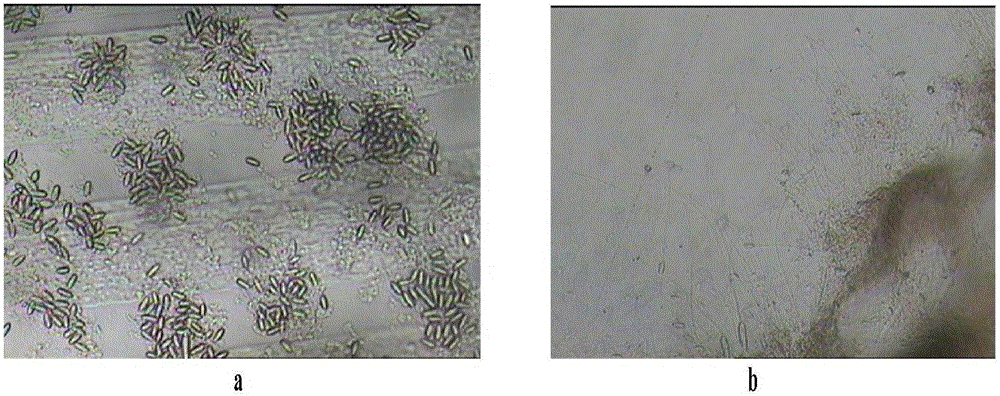

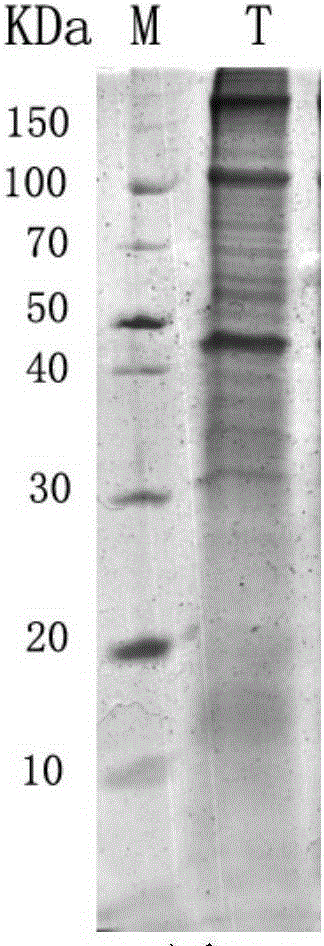

[0027] 1) Preparation of the crude poison of the white jellyfish: Take 100g of the tentacles of the white jellyfish, put them in a -80°C ultra-low temperature refrigerator for 24 hours, add 400g of pH 7.0 Tris-HCl buffer solution containing NaCl at 0-6°C, and the NaCl concentration is 0.1mol / L, pH 7.0 Tris-HCl concentration 10mmol / L, stirred until the tentacles melted, centrifuged at 8000g for 5min at 0-6°C, collected the supernatant buffer, concentrated to 5ml with a 3K ultrafiltration tube at 0-6°C.

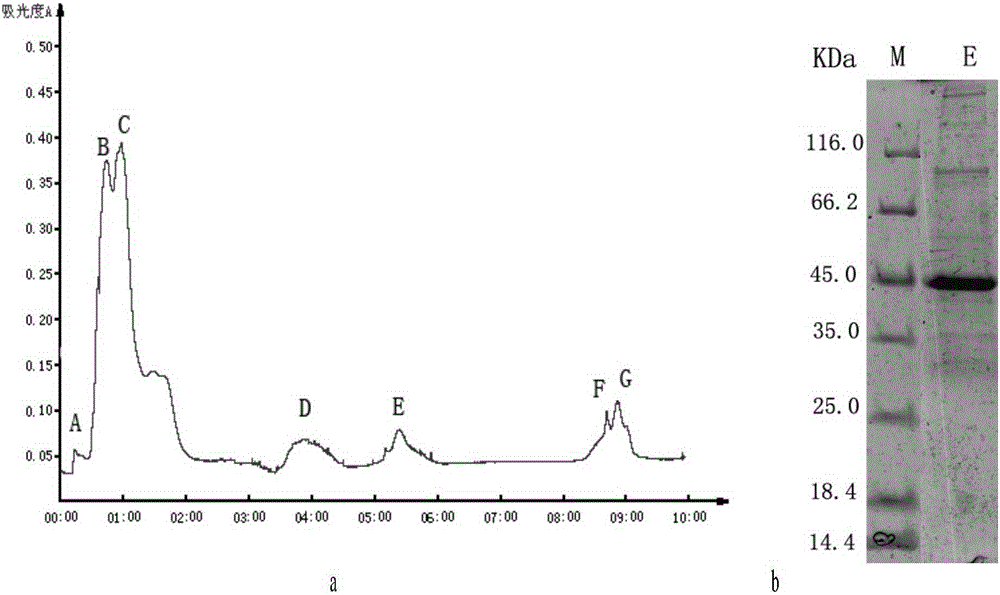

[0028] 2) The crude poison obtained in step 1) was filtered through a microporous membrane with a pore size of 0.45 μm, and then separated by DEAESepharose FastFlow (2.6×10 cm), and eluted step by step, and the eluent was pH 7.0 Tris- HCl, the flow rate is 3ml / min, collect the eluate in the 900-1080ml section, and concentrate it to 2ml with a 3K ultrafiltration tube at 0-6°C.

[0029] The eluent was 10mmol / L, pH7.0 Tris-HCl containing 0, 0.1, 0.2, 0.5mol / L NaCl respectively. ...

Embodiment 2

[0039]1) Preparation of the crude poison of the white jellyfish: take 150g of the tentacles of the white jellyfish, put them in a -80°C ultra-low temperature refrigerator for 48 hours, add 300g of pH7.1 Tris-HCl buffer solution containing NaCl at 0-6°C, and the NaCl concentration is 0.15mol / L, stirred until the tentacles melted, centrifuged at 10000g for 10min at 0-6°C, collected the supernatant buffer, and concentrated to 5ml with a 5K ultrafiltration tube at 0-6°C.

[0040] 2) Filter the crude poison obtained in step 1) with a microporous membrane with a pore size of 0.45 μm, and then separate it on DEAESepharose FastFlow (2.6x10cm), and use step-by-step elution, and the eluent is: 15mmol / L, pH 7.1 Tris-HCl, flow rate 2.5ml / min, collect 900-1080ml eluate, concentrate to 2ml with 5K ultrafiltration tube at 0-6°C.

[0041] The eluent was 10mmol / L, pH7.1 Tris-HCl containing 0, 0.1, 0.2, 0.5mol / L NaCl respectively.

[0042] 3) The concentrated solution obtained in step 2) is ...

Embodiment 3

[0045] 1) Preparation of the crude poison of the white jellyfish: Take 200g of the tentacles of the white jellyfish, put them in a -80°C ultra-low temperature refrigerator for 72 hours, add 300g of pH7.2 Tris-HCl buffer solution containing NaCl at 0-6°C, and the NaCl concentration is 0.2mol / L, stirred until the tentacles melted, centrifuged at 10000g for 20min at 0-6°C, collected the supernatant buffer, and concentrated to 5ml with a 10K ultrafiltration tube at 0-6°C.

[0046] 2) Filter the crude poison obtained in step 1) with a microporous filter membrane with a pore size of 0.45 μm, and then separate it on DEAESepharose FastFlow (2.6x10cm), and use step-by-step elution, and the eluent is: 20mmol / L, pH 7.2 Tris-HCl, flow rate 2ml / min, collect the eluate from 900-1080ml segment, and concentrate to 2ml with a 10K ultrafiltration tube at 0-6°C.

[0047] The eluent was 10mmol / L, pH7.2 Tris-HCl containing 0, 0.1, 0.2, 0.5mol / L NaCl respectively.

[0048] 3) The concentrated so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com