A linear eye drop bottle washing, filling, stoppering and capping integrated machine and method

A kind of technology of eye drops and linear type, which is applied in the field of stoppering and capping machine, linear eye drop bottle washing, and filling field, which can solve the trouble of debugging and maintenance of the disc layout structure, unstable operation and handover of equipment, and aseptic control Problems such as high cost, to avoid insufficient space for debugging and maintenance, stable and reliable gantry structure, increase the number of channels and the effect of production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

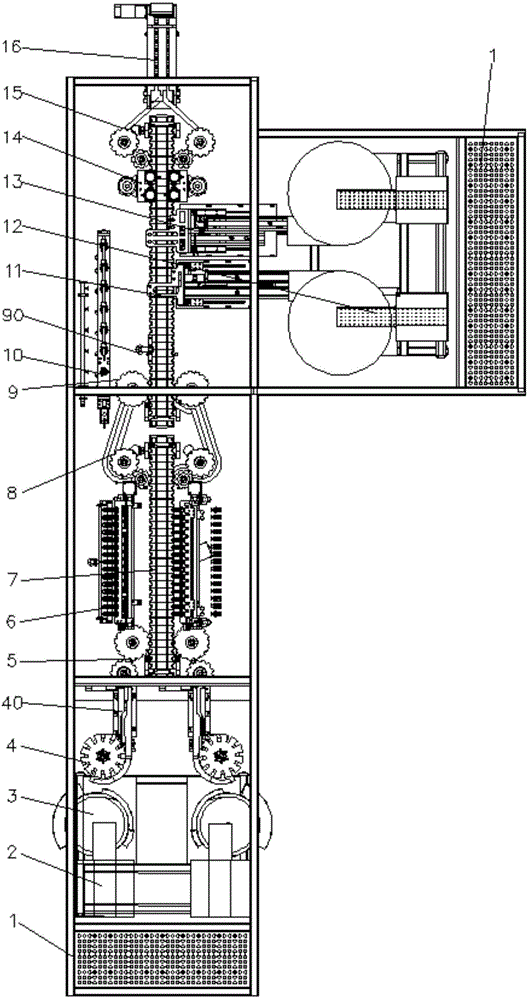

[0035] Please refer to figure 1 , the present invention provides a linear eye drops bottle washing, filling, capping and capping integrated machine, including bottle washing and conveying synchronous belts and filling, capping, capping and bottle feeding synchronous belts arranged side by side.

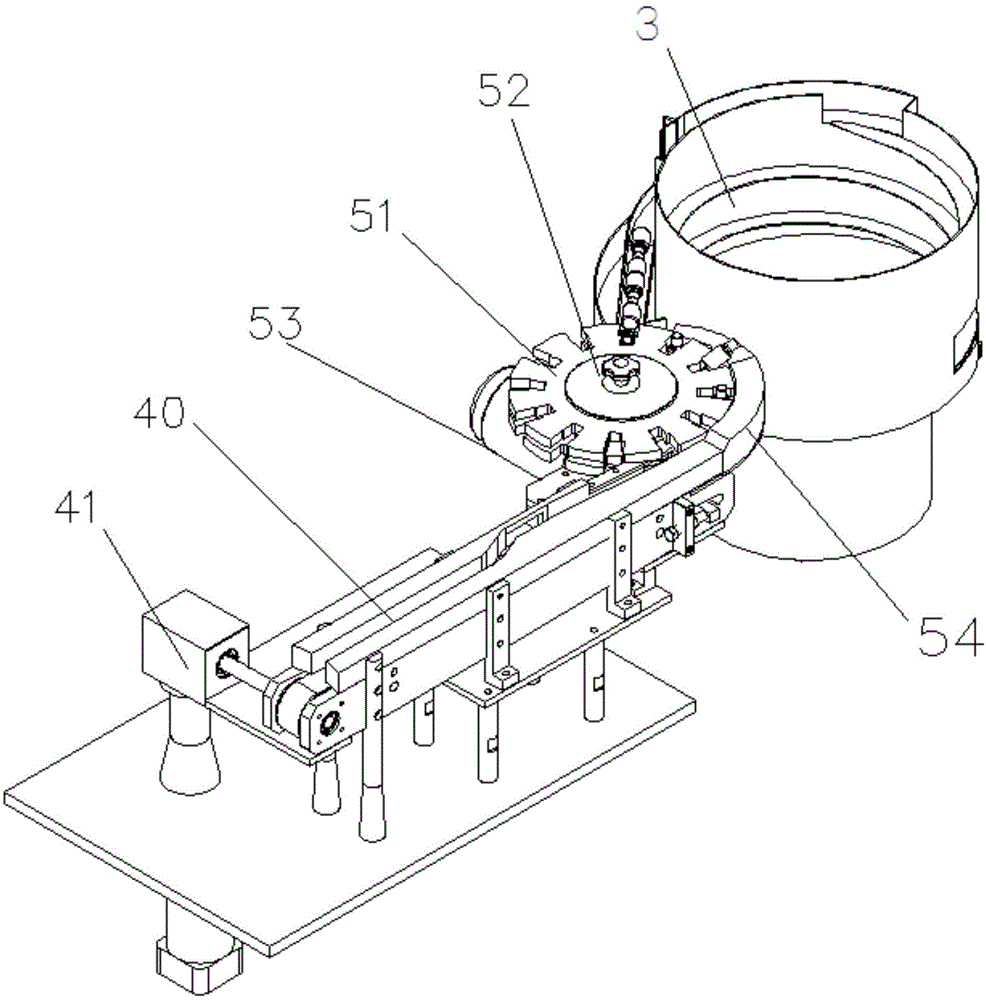

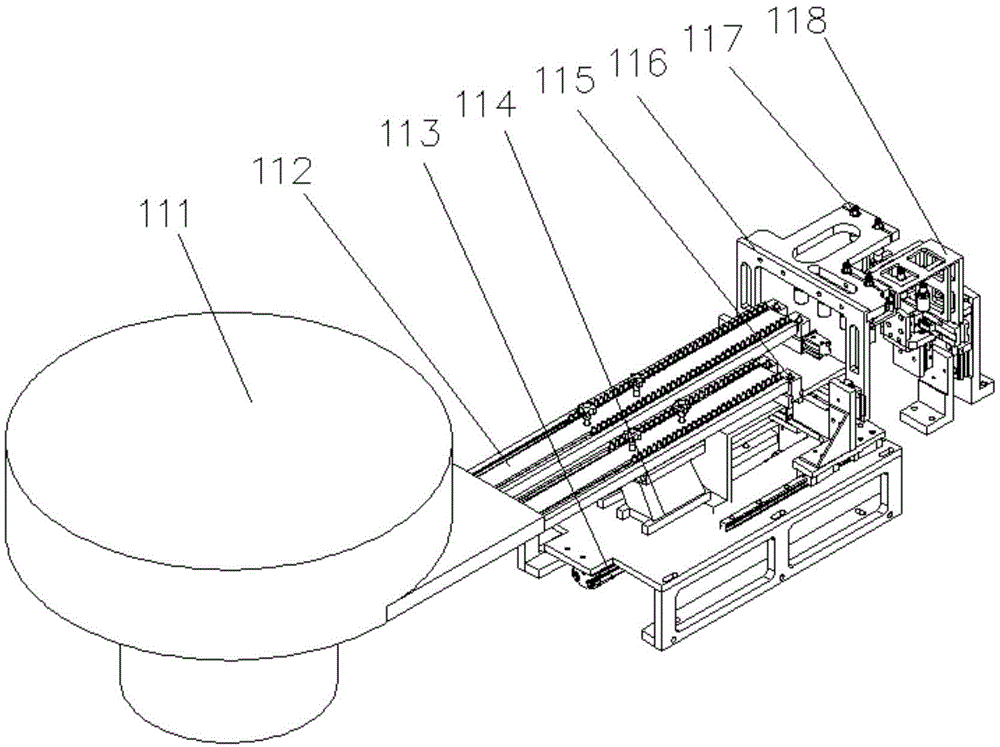

[0036] Please refer to figure 1, the bottle washing conveying synchronous belt includes a straight-line symmetrically arranged flat vibrating feeding hopper 2, a disc oscillator 3, a dial wheel bottle straightening mechanism 4, a conveying track 40, an air washing bottle feeding dial mechanism 5, a washing machine Bottle conveyer belt 7 and ion air washing mechanism 6 and washing bottle go out dial wheel and barrier 8.

[0037] Please refer to figure 1 , the filling, stoppering, capping and bottle feeding synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com