Material drive device of flat head machine

A material-driven, flat-mouth machine technology, applied in the field of flat-mouth machines, can solve the problems of poor material conveying distance, affecting the overall size of the fresh-keeping bag, and material conveying asynchronously, achieving consistent clamping force, ensuring overall size, and material conveying synchronization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

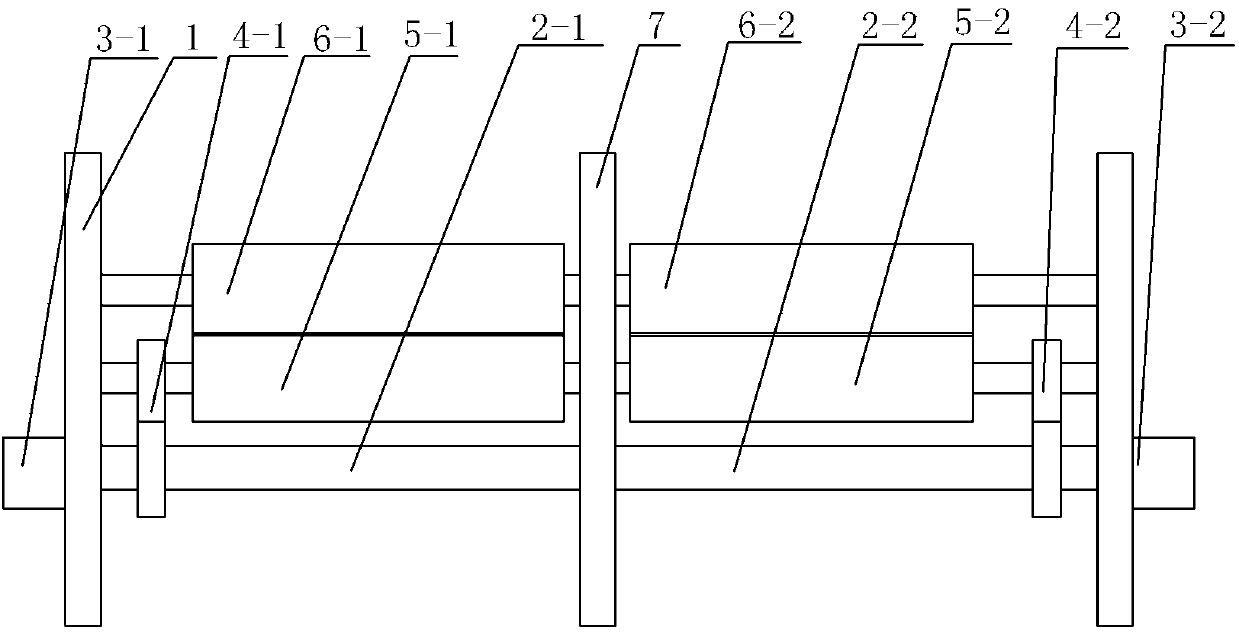

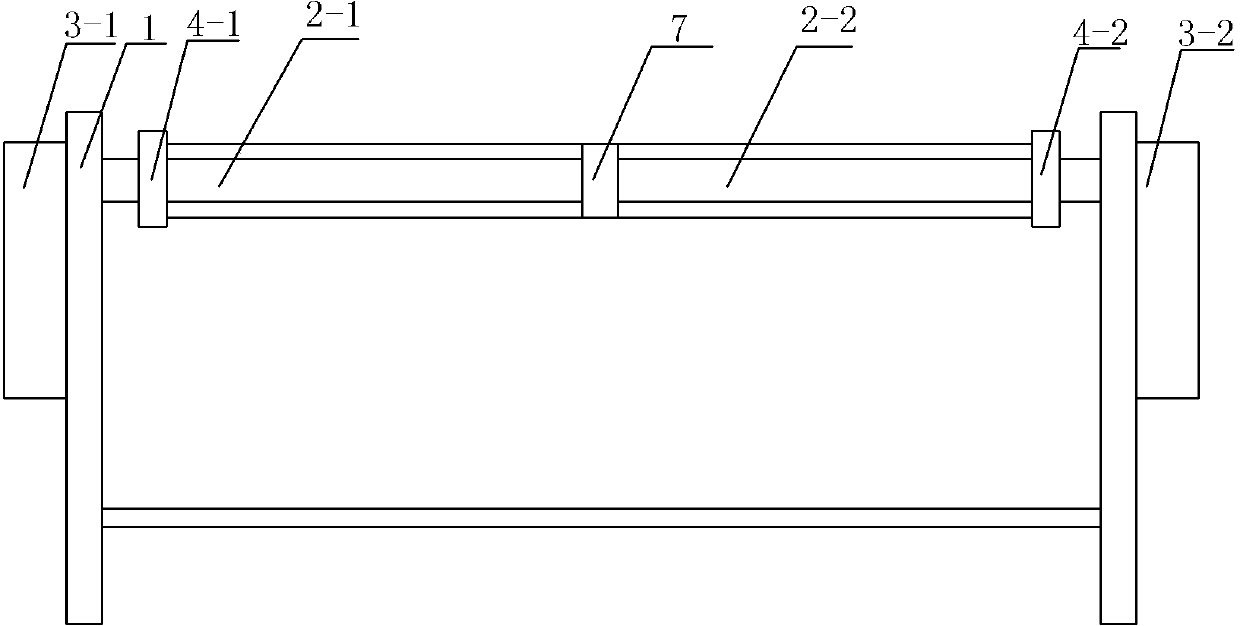

[0009] See figure 1 , figure 2 As shown, a material driving device of a flat mouth machine includes a frame 1, and driving rollers 2-1 and 2-2 are respectively arranged on both sides of the frame 1, and the driving rollers 2-1 and 2-2 are respectively connected synchronously Motor 3-1, 3-2, driving roller 2-1, 2-2 are connected driving roller 5-1, 5-2 through gear 4-1, 4-2, and frame 1 is provided with and driving roller 5-1, 5-2 parallel passive rollers 6-1, 6-2, driving rollers 5-1, 5-2 contact with passive rollers 6-1, 6-2, driving rollers 5-1, 5-2 drives the driven rollers 5-1, 5-2.

[0010] One end of the driving rollers 2-1, 2-2, the driving rollers 5-1, 5-2 and the driven rollers 6-1, 6-2 is supported by the supporting frame 7 in the middle of the frame 1 .

[0011] The driving roller drives the active roller through the gear, and the active roller drives the passive roller to realize the material transportation. Since the synchronous motor drives the driving roller...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap