Convenient Aluminum Wheel Mold Heating Tool

A mold heating and aluminum wheel technology, which is applied in the manufacture of tools, metal processing equipment, casting molds, etc., can solve the problem of high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

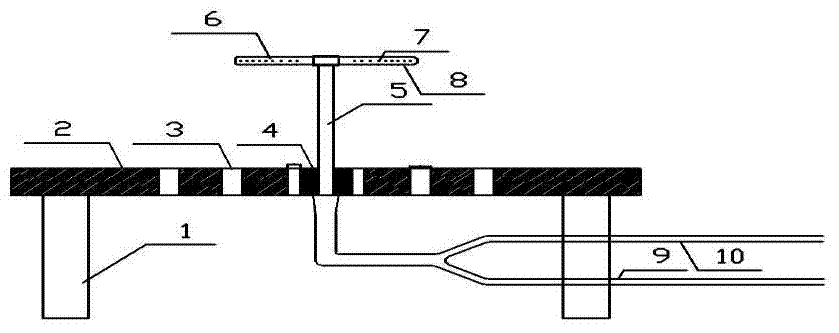

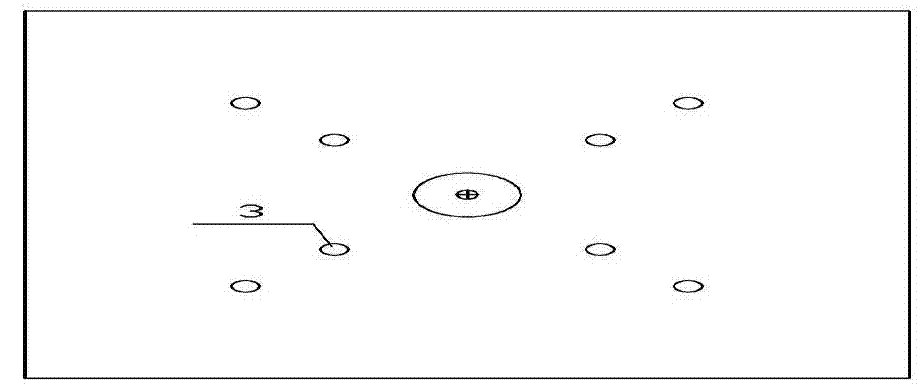

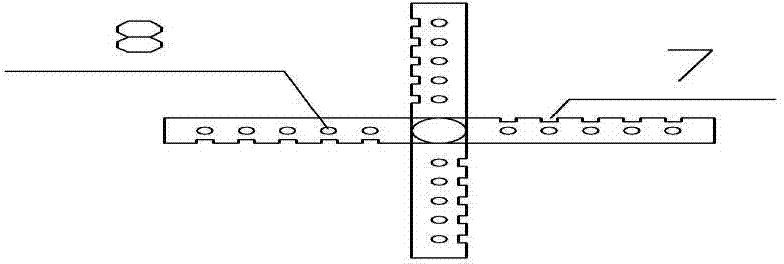

[0008] Such as figure 1 , 2 As shown in , 3, a portable aluminum wheel hub mold heating tool is composed of a baking mold workbench 2, a baking mold pillar 1, a small baking mold bracket 5, a baking mold ten bracket 6, a natural gas pipeline 9, and a compressed air pipeline 10. The cooling holes 3 are evenly distributed on the mold worktable 2, the bearing 4 communicating with the compressed air pipeline 10 and the natural gas pipeline 9 is distributed in the middle part of the baking mold workbench 2, and the side fire outlet is distributed at one end of the baking mold cross 6 7 and the following air outlet 8, the side fire outlet 7 and the following air outlet 8 are in the same direction. When baking the mold, align the mold gate with the bearing 4 and put it in place. Assemble the baking mold small bracket 5 and the baking mold cross 6 and put them into the bearing 4. The natural gas and compressed air are transmitted to the baking mold small bracket 5 and the baking mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com