A wheat no-tillage seeder suitable for full straw-covered land operation

A seeder and wheat technology, which is applied in the field of seeders, can solve the problems of easy seed drying, surface soil compaction, and field inequality, and achieve the effect of reducing the rate of seed drying and improving the quality of covering soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

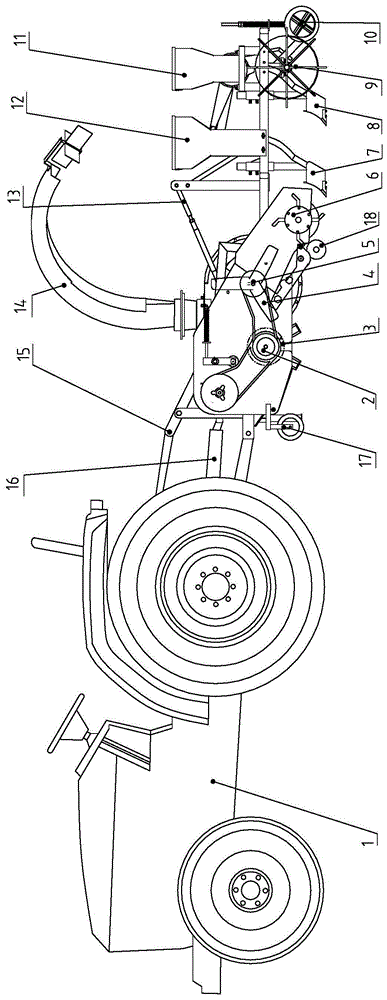

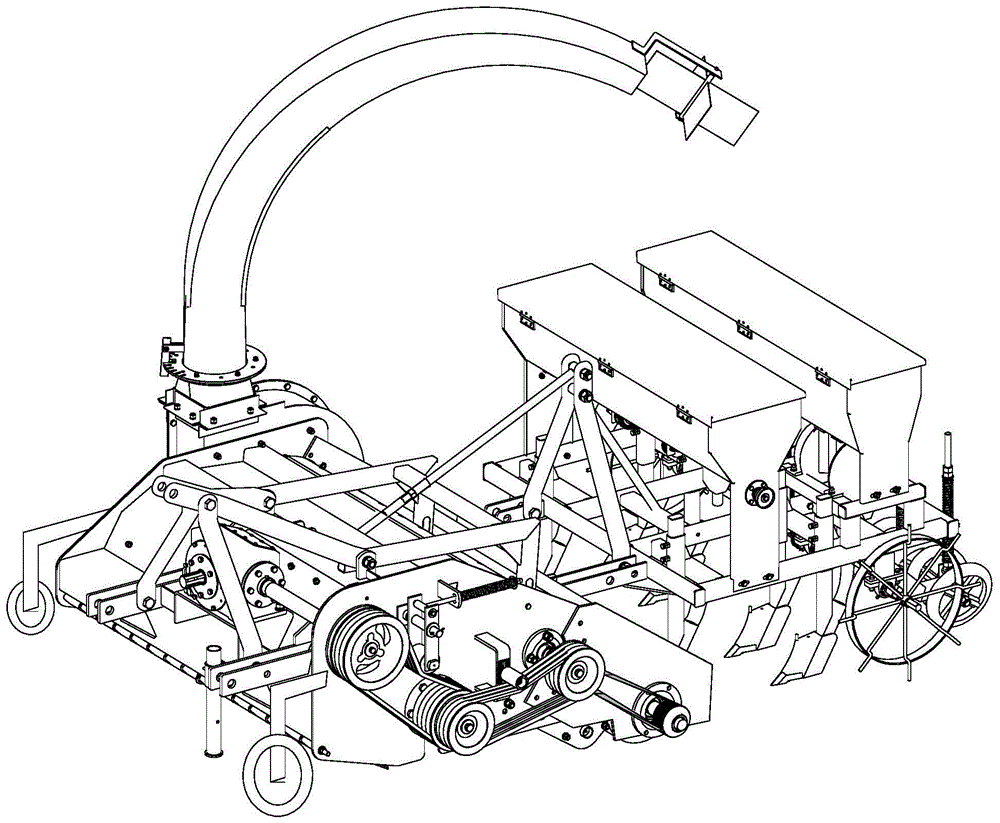

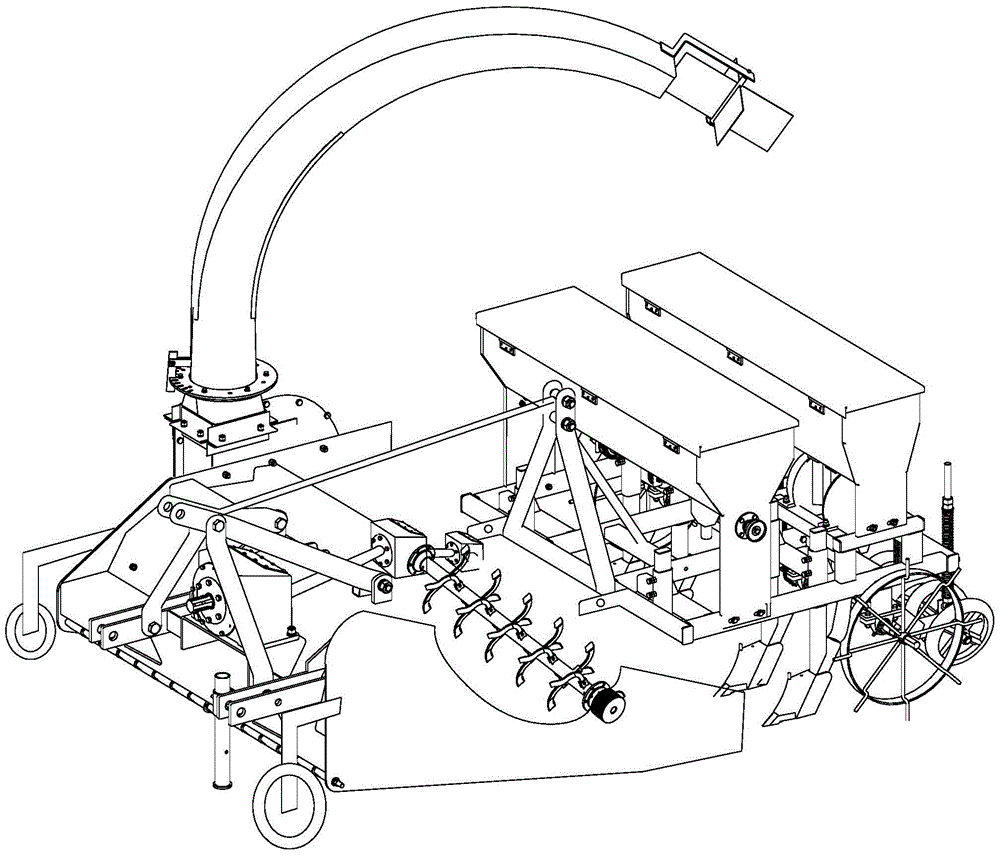

[0040] The structure of the present invention will be described in further detail below in conjunction with the drawings.

[0041] A wheat no-tillage planter suitable for full-straw mulch work, with the following configuration from front to back:

[0042] The tractor power output shaft 16 is connected to the rotary knife shaft 3 of the horizontal wide box type straw crushing and cleaning machine. The knife shaft 3 is equipped with multiple straw crushing knives 2, and the multiple straw crushing knives 2 are arranged in a spiral manner. On the knife shaft 3, behind the straw crushing knife 2 is a horizontal auger 5, and the output end of the horizontal auger 5 is equipped with a fan 4, which is sent to the top of the wheat fertilizer planter through the pipeline;

[0043] The straw thrown by the straw throwing device 14 is equivalent in width to the width of the wheat fertilizing planter; it can crush and remove the straw after the harvest of the previous crops of corn, rice, and cot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com