Ultrasonic flowmeter

An ultrasonic and flowmeter technology, used in the measurement of flow/mass flow, liquid/fluid solid measurement, measurement devices, etc., can solve problems such as inability to measure flow with high accuracy, measurement flow, error, etc., and achieve the effect of high-precision flow measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The ultrasonic flowmeter of the present invention will be described below with reference to the drawings.

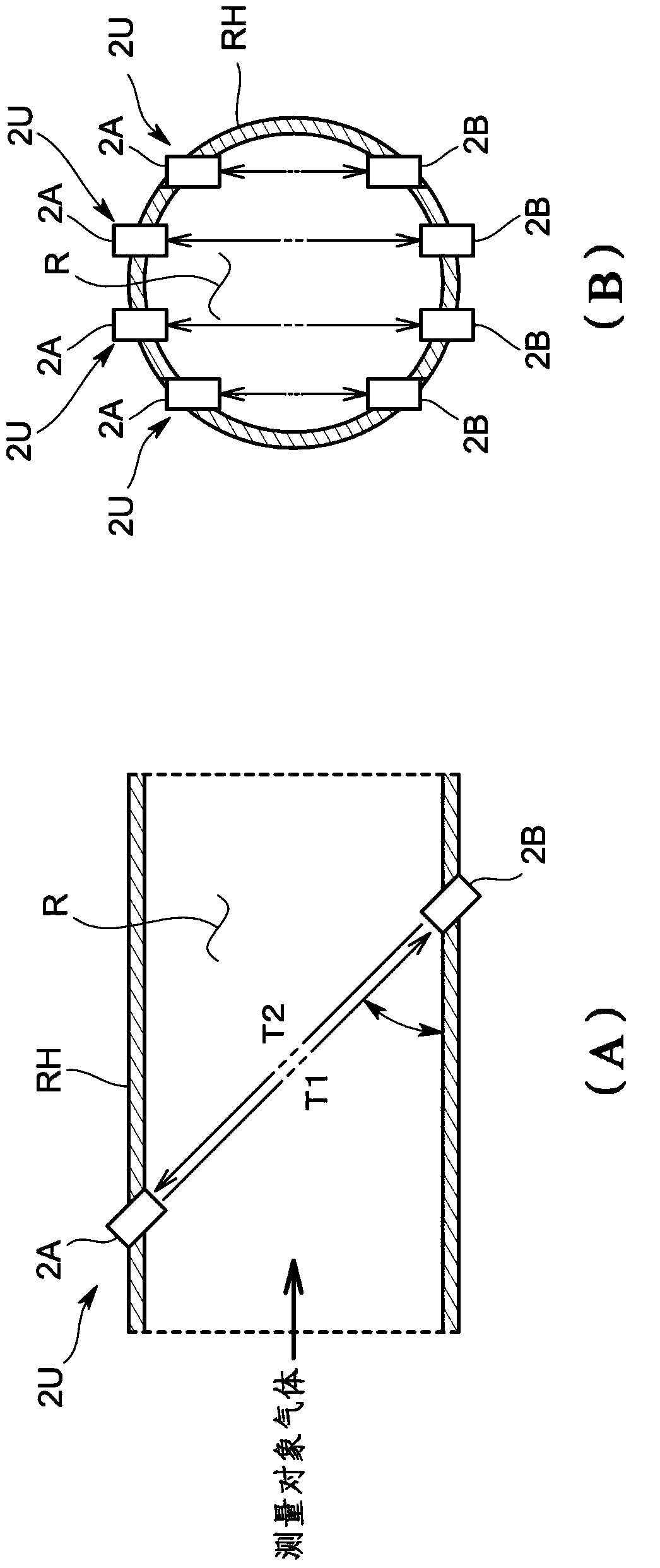

[0045] The ultrasonic flowmeter 100 of the present embodiment is used in a gas analysis system that analyzes components contained in a gas to be measured, such as exhaust gas discharged from an engine, etc. The gas flow pipe RH of the gas is used to measure the flow rate of the measurement target gas flowing through the flow channel R of the gas flow pipe RH.

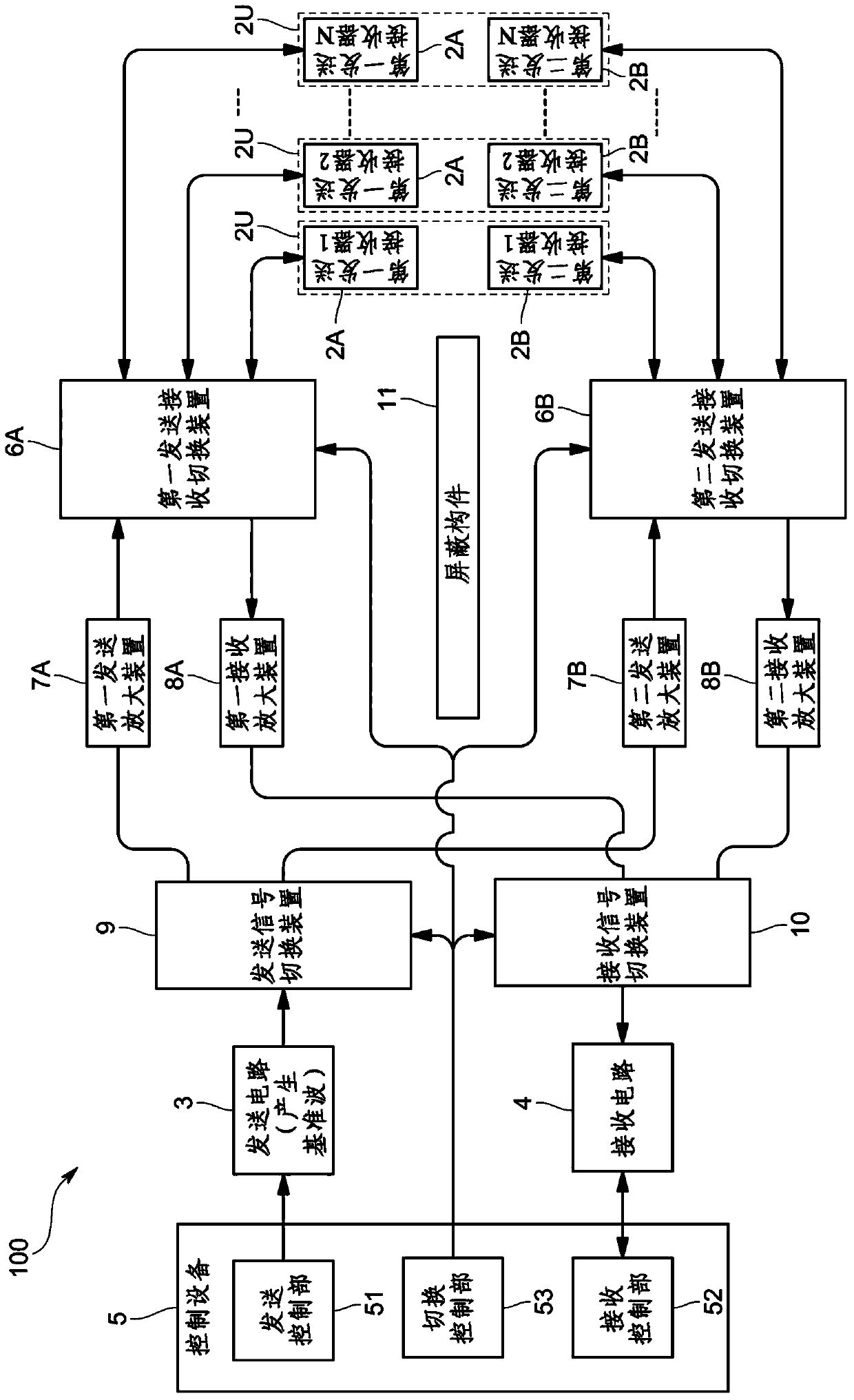

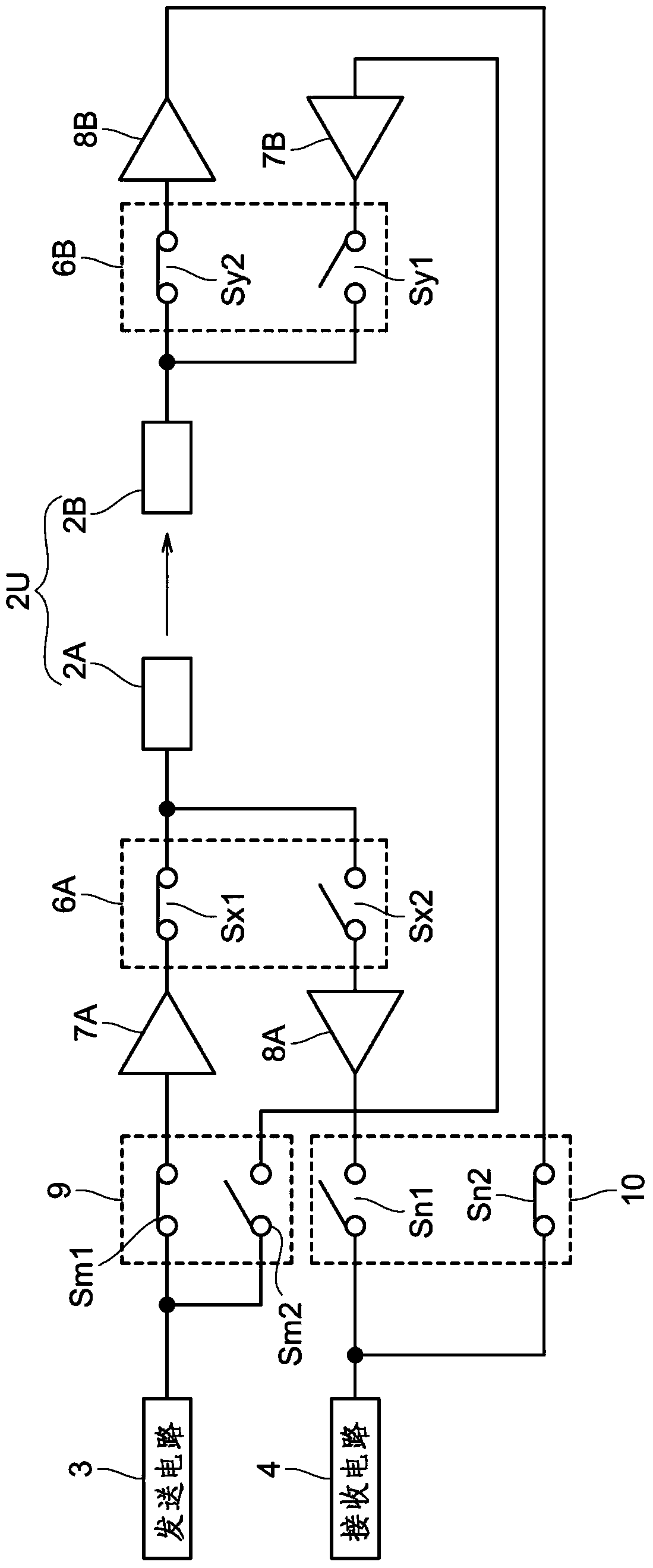

[0046] Specific as figure 1 As shown in (A), the ultrasonic flowmeter 100 has a plurality of pairs of first ultrasonic transmitter receivers 2A and second ultrasonic transmitter receivers arranged obliquely in the flow channel R of the gas flow pipe RH 2B. In the present embodiment, the first ultrasonic transceiver 2A is installed on the upstream side, and the second ultrasonic transceiver 2B is installed on the downstream side. In addition, if figure 1 As shown in (B), in the plurality of ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com