A kind of pulling reel hose assembly

A technology of hose assembly and plucking wheel, which is applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc. To the effect of compact structure, improved service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

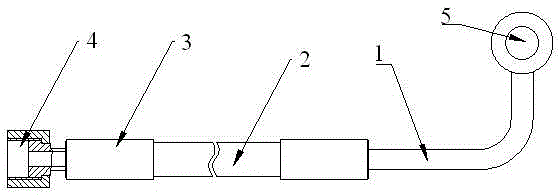

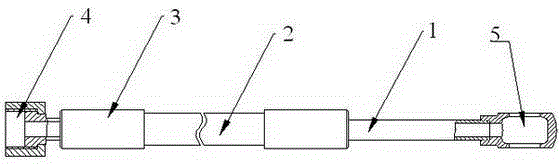

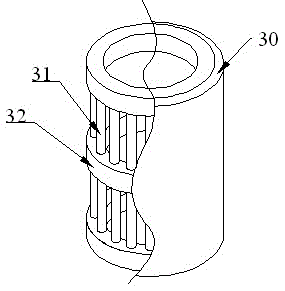

[0024] Such as figure 1 , figure 2 as well as image 3 As shown, a puller hose assembly includes a hose 1, a rubber hose 2, a sleeve 3, a nut 4 and a ball joint 5, and the nut 4 and the rubber hose 2 are connected to the rubber hose in a socket type. Both ends of 2 and the surface of the connection are provided with sleeves 3; the sleeve 3 includes a casing 30, a needle roller 31 and a connecting ring 32; the casing 30 is fixed on the outermost side of the sleeve 3; there are three connecting rings 32, which are respectively located The upper, middle and lower positions of cylinder 3. The needle rollers 31 all pass through the connecting ring 32 in the middle, and the two ends are respectively located in the upper and lower connecting rings 32. The sleeve with this structure has a compact radial structure, can withstand higher radial loads, and its rigidity It is higher than the general cylindrical sleeve, and the needle roller 31 can freely roll relative to the connectin...

Embodiment 2

[0028] Same as embodiment 1, the difference is that the number of needle rollers 31 is preferably 20, increasing the number of needle rollers 31 makes the radial load capacity of the sleeve 3 higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com