Transmission shaft for circuit breaker and circuit breaker poking mechanism using same

A technology of toggle mechanism and transmission shaft, applied in high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of long transmission stroke, low transmission efficiency, complex structure, etc., and achieve low transmission energy consumption, short transmission stroke, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

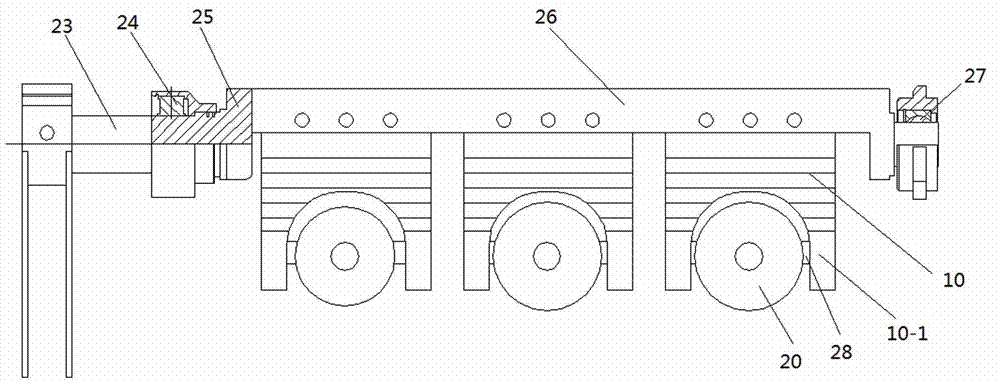

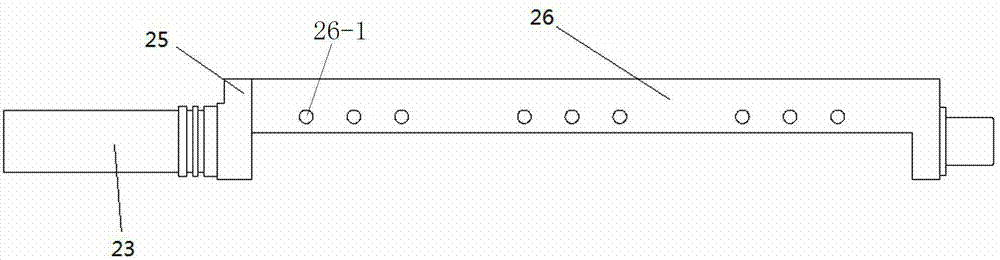

[0021] Examples of drive shafts for circuit breakers are image 3 Shown: It includes a crankshaft body with a main shaft diameter 23, a connecting rod 25 and a connecting rod shaft diameter 26. The main shaft diameter is used for transmission connection with the power output end of the corresponding operating mechanism, and the connecting rod shaft diameter has a flat plate structure , the connecting rod shaft diameter 26 is provided with three shift fork fixing structures at intervals along its axial direction, which are respectively used to fix the corresponding insulating shift forks. The mounting plate is used for the corresponding connecting bolts to pass through to realize the bolt perforation 26-1 for the fixed assembly of the shaft diameter of the connecting rod and the corresponding insulating shift fork.

[0022] In other embodiments of the drive shaft for the circuit breaker: there may be multiple shaft diameters of the connecting rods, and at this time, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com