Rocket based combined cycle engine rocket ejector T-type layout

A technology for ejecting rockets and combined power, which is applied to rocket engine devices, machines/engines, and mechanical equipment, etc. In order to reduce the congestion effect and flight resistance, optimize the performance of the engine and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

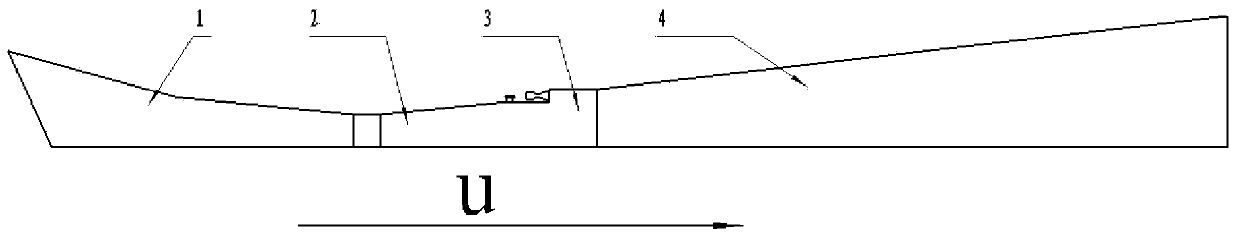

[0021] This embodiment is a rocket-based combined power cycle engine ejection rocket T-shaped layout.

[0022]The rocket-based combined power cycle engine ejection rocket T-shaped layout of the present invention, by constraining the size of the height difference between the mixing section 3 and the isolation section 2 and the height dimension of the ejection rocket 6 half-penetrating through the central support plate, the duty cycle is smaller than the existing one. The layout mode of the fully penetrating support plate type ejection rocket, the shear area of the primary flow and the secondary flow is larger than that of the T-type ejection rocket layout method of the existing side wall type ejection rocket layout method. The air flow direction is shown as u in the figure. The air flow enters the isolation section 2 after being compressed from the inlet channel 1, and the ejector rocket combustion chamber transmits the high-temperature and high-pressure gas generated by combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com