Construction method for improving percent of pass of double-block type concrete sleepers

A construction method and concrete technology, which are applied in the directions of tracks, roads, ballast layers, etc., can solve the problem that the double-block sleeper prefabrication technology is difficult to achieve the construction effect, the double-block sleeper prefabrication is difficult to construct, and the welding point of the thermal variation range is not firm. and other problems to achieve the effect of avoiding detachment, removing stress, and reducing instantaneous current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

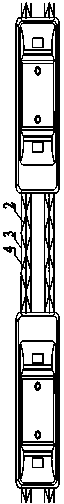

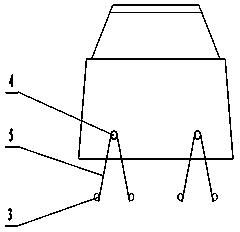

[0022] Below is a kind of concrete embodiment of invention, and construction is constructed by following process; First make steel bar truss, get the cold-rolled ribbed steel bar that makes steel bar truss upper chord bar 4, lower chord bar 3 and corrugated bar 2 and leave standstill for 7 days respectively at normal temperature As above, ensure that the stress generated by the cold-rolled ribbed steel bar in the steel bar cold-rolling process is completely released, and then adjust the straightness of the cold-rolled ribbed steel bar that has been standing for more than 7 days to intercept the upper chord bar 4 and the lower chord bar 3 respectively, and use a bending machine Make the corrugated bar 2, and increase the height of the arch by 1-2mm when bending; then set the upper chord bar 4 and the lower chord bar 3 according to the original distance, and weld them together through the corrugated bar 2, because the arch height of the corrugated bar 2 is adjusted The height is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com