Conical roller bearing automatic feed and face recognizing machine

A tapered roller bearing and automatic feeding technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of wasting manpower, low production efficiency, unable to guarantee consistent upward or downward, etc., to save costs and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

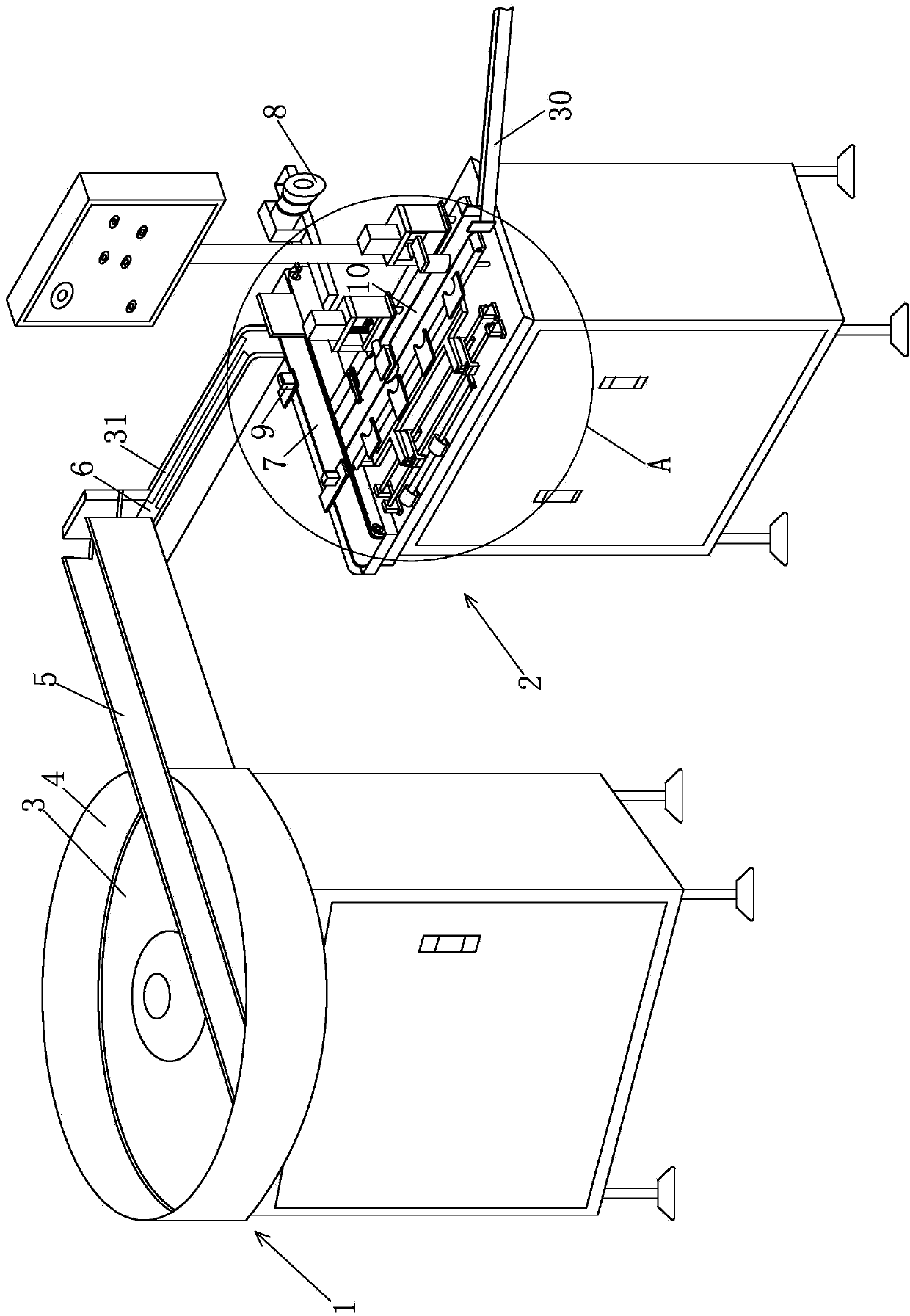

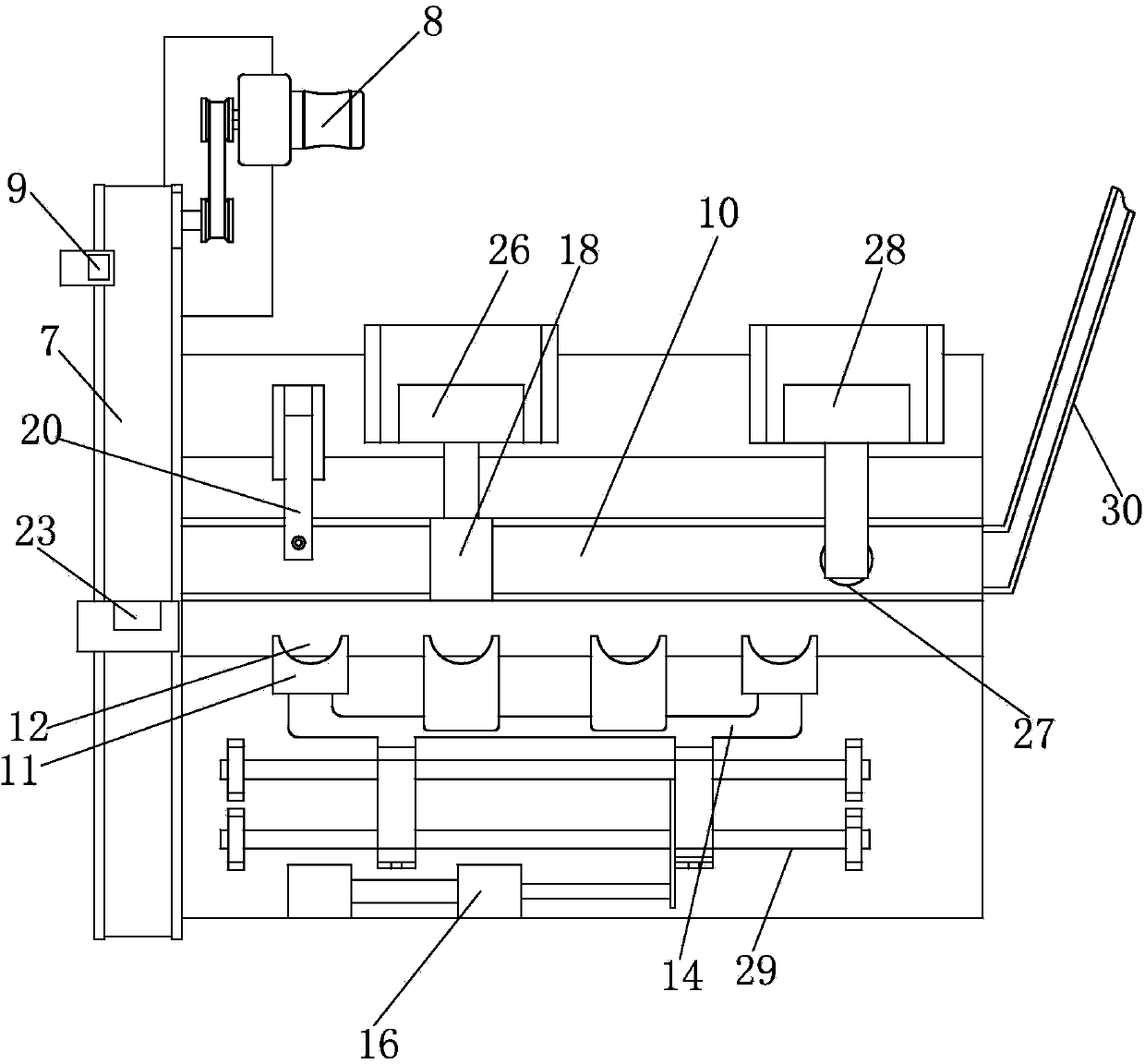

[0022] Example: such as Figure 1~4 As shown, a tapered roller bearing automatic feeding surface recognition machine of the present invention includes a feeding device 1 and a surface recognition system 2. The feeding device 1 includes a circular feeding turntable 3 inclined with respect to a horizontal plane. The angle between the disc surface of the feeding turntable 3 and the horizontal plane is 20-30 degrees. The circular feeding turntable 3 is connected with a turntable driving device that drives it to rotate. The turntable driving device is the prior art, and is along the periphery of the circular feeding turntable 3. There is a circle of baffle 4, and a feeding trough 5 is provided at the bottom end of the surface of the circular feeding turntable 3. One end of the feeding trough 5 is in the turntable, and the other end passes through the baffle 4. Before work, pour the bearing into Inside the circular feeding turntable 3, the circular feeding turntable 3 continuously ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com