Cloth feeding and dipping device on hollow composite slab production line

A technology of dipping device and production line, applied in the field of cloth dipping device, can solve the problems of long production cycle, uneven resin content, inability to continuously automate production, etc., achieve precise control of flatness and height dimensions, improve standability and High uniformity, the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

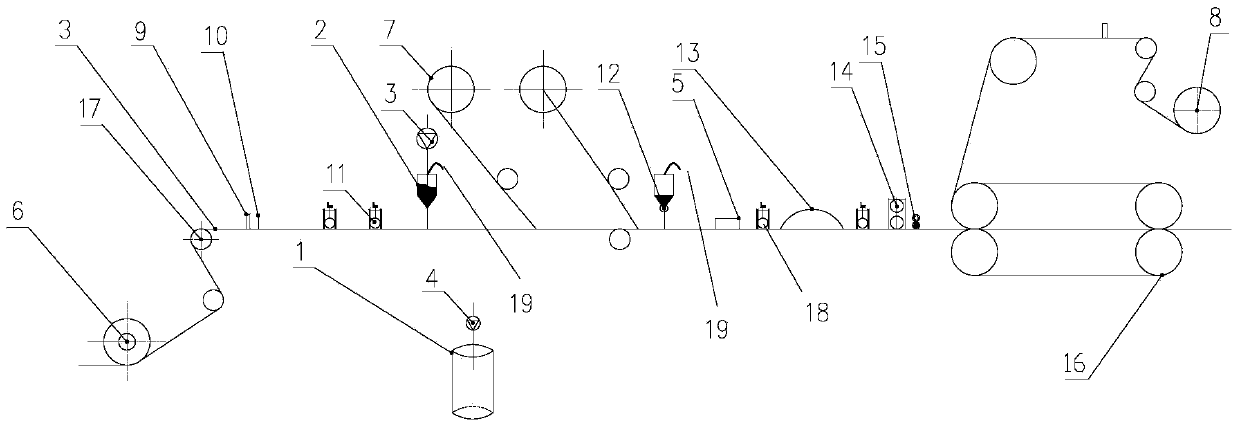

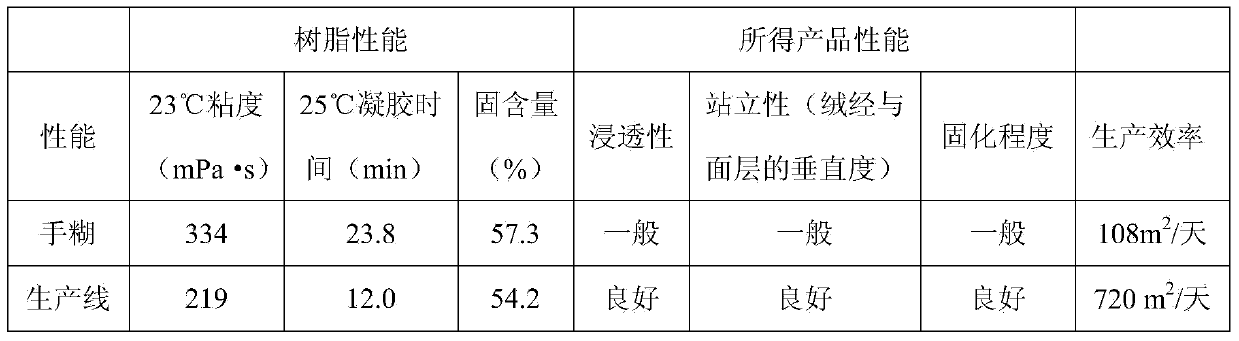

[0023] Such as figure 2 The cloth dipping device on the hollow composite flat production line shown includes the glue dispensing device, the frame platform and the lower film unwinding machine, glue distribution device, first soaking roller, and hollow cloth unwinding device arranged in sequence along the frame platform. Machine, multi-roll constant tension active unwinding mechanism, auxiliary standing device, film unwinding machine and power thickness controller; multi-roll constant tension active unwinding mechanism is equipped with constant tension control rollers; glue distribution device and glue distribution device pass through the hose connected. There is a traction device between the upper film unwinder and the power thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com