Universal die slide structure

A sliding seat and mold technology, which is applied in the field of mold universal sliding seat structure, can solve problems such as product scrapping, slanted roof seizure, and affecting production efficiency, so as to reduce mold repair time, reduce mold material consumption, and improve yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

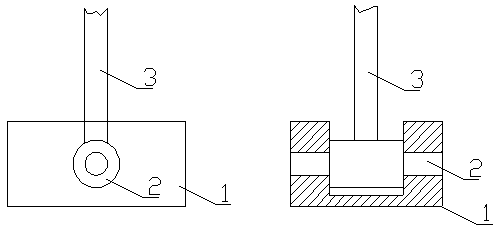

[0008] Depend on figure 1 Known, a mold universal slide seat structure, including a base 1, a rotating shaft 2 and an ejector rod 3, the ejector rod 3 is welded in the middle of the rotating shaft 2, and the two ends of the rotating shaft 2 are located in the slider base 1, And can rotate freely. When the universal sliding seat structure is demolded, the base 1 rises, the rotating shaft 2 is pressed by the ejector rod 3 and the base 1 and starts to rotate, and the ejector rod 3 swings along with the rotating shaft 2 to eject the product obliquely.

[0009] In the present invention, by introducing a mold universal sliding seat structure into the mold structure, the problem of slanted roof seizure is solved, the mold repair time and mold material consumption are reduced, and the yield of products is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com