Automatic assembling machine for lamp bracket

An assembly machine and automatic technology, which is applied in the field of automatic assembly machines for lamp stands, can solve the problems of many manpower, high labor intensity, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

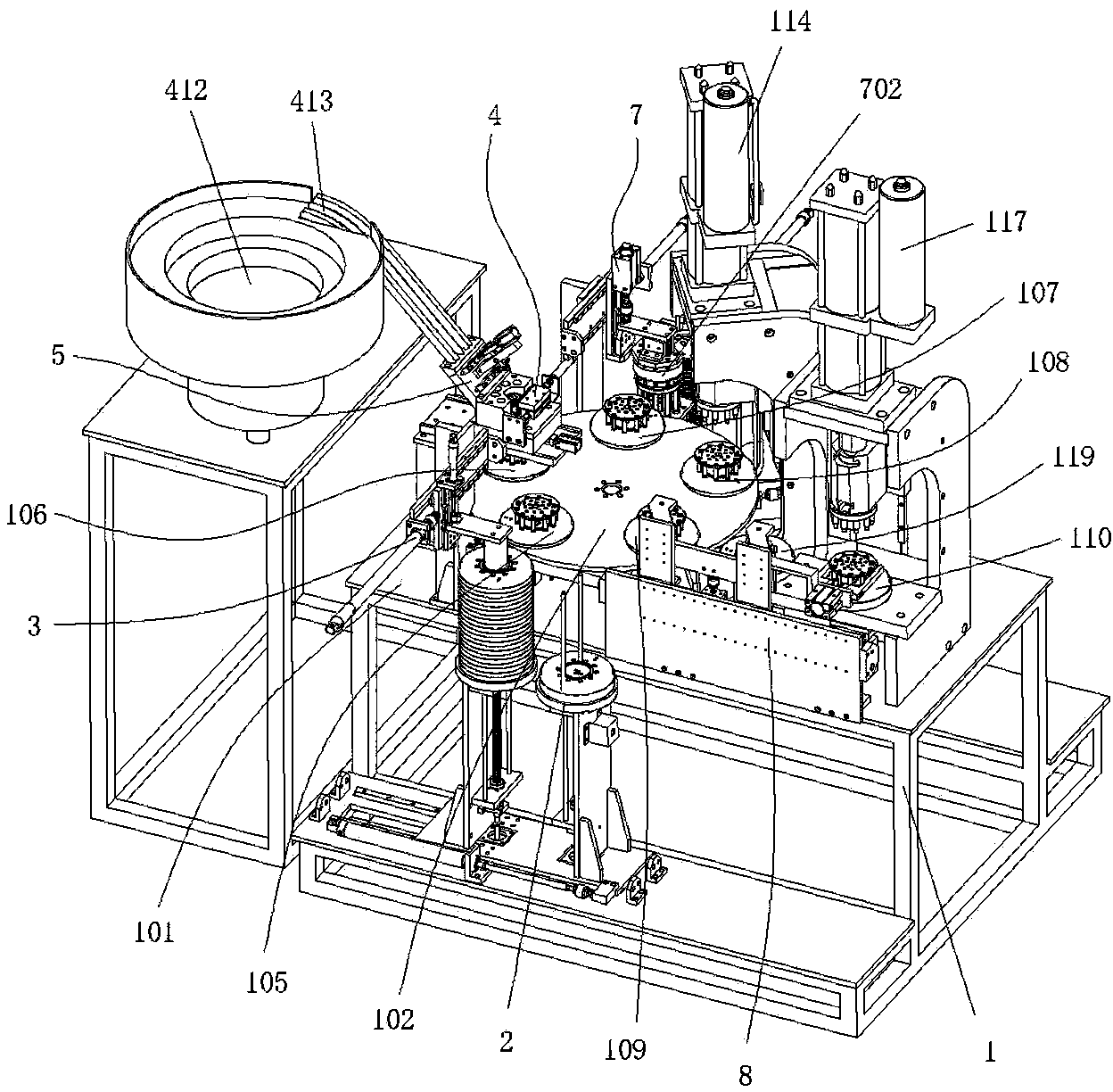

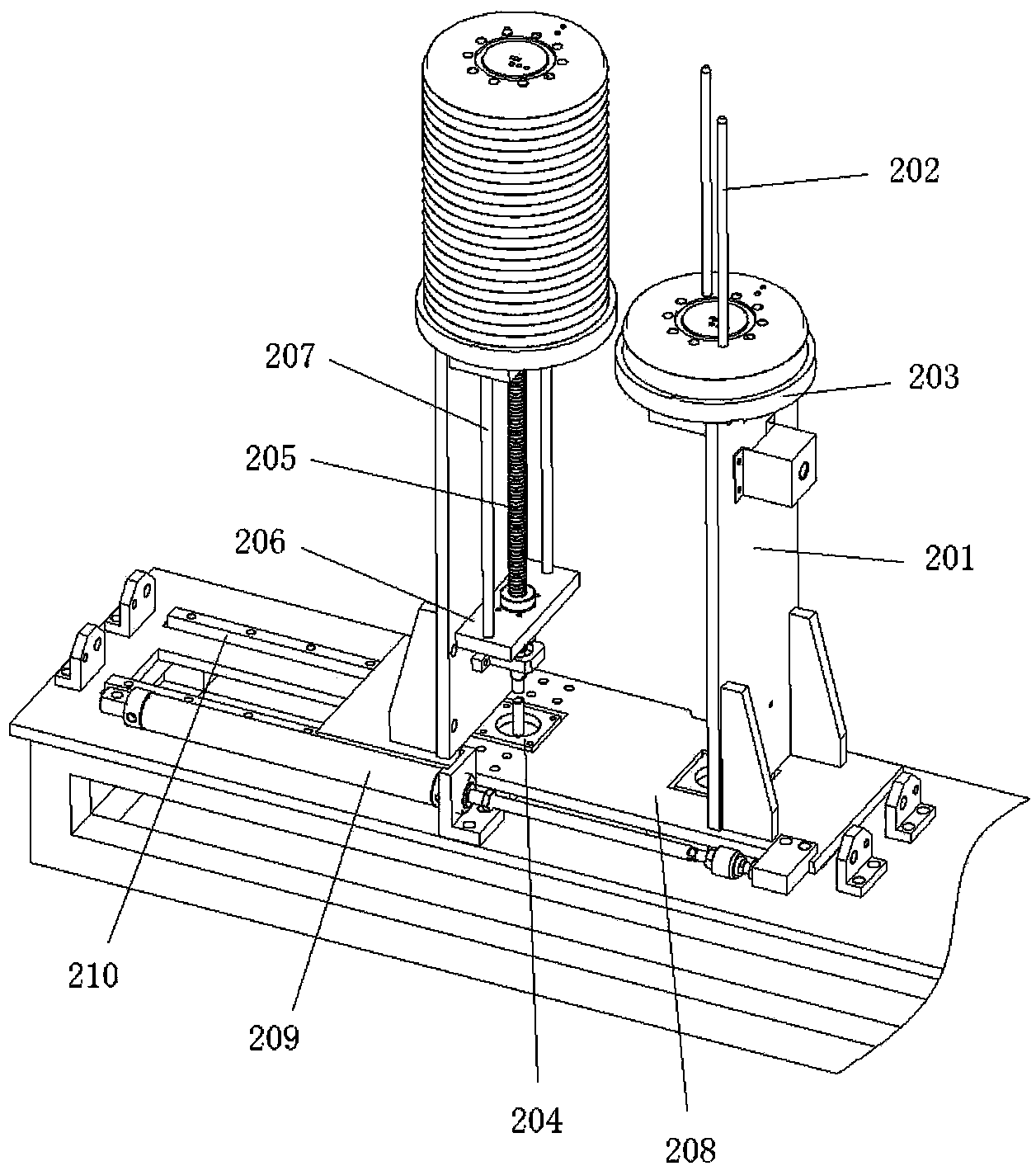

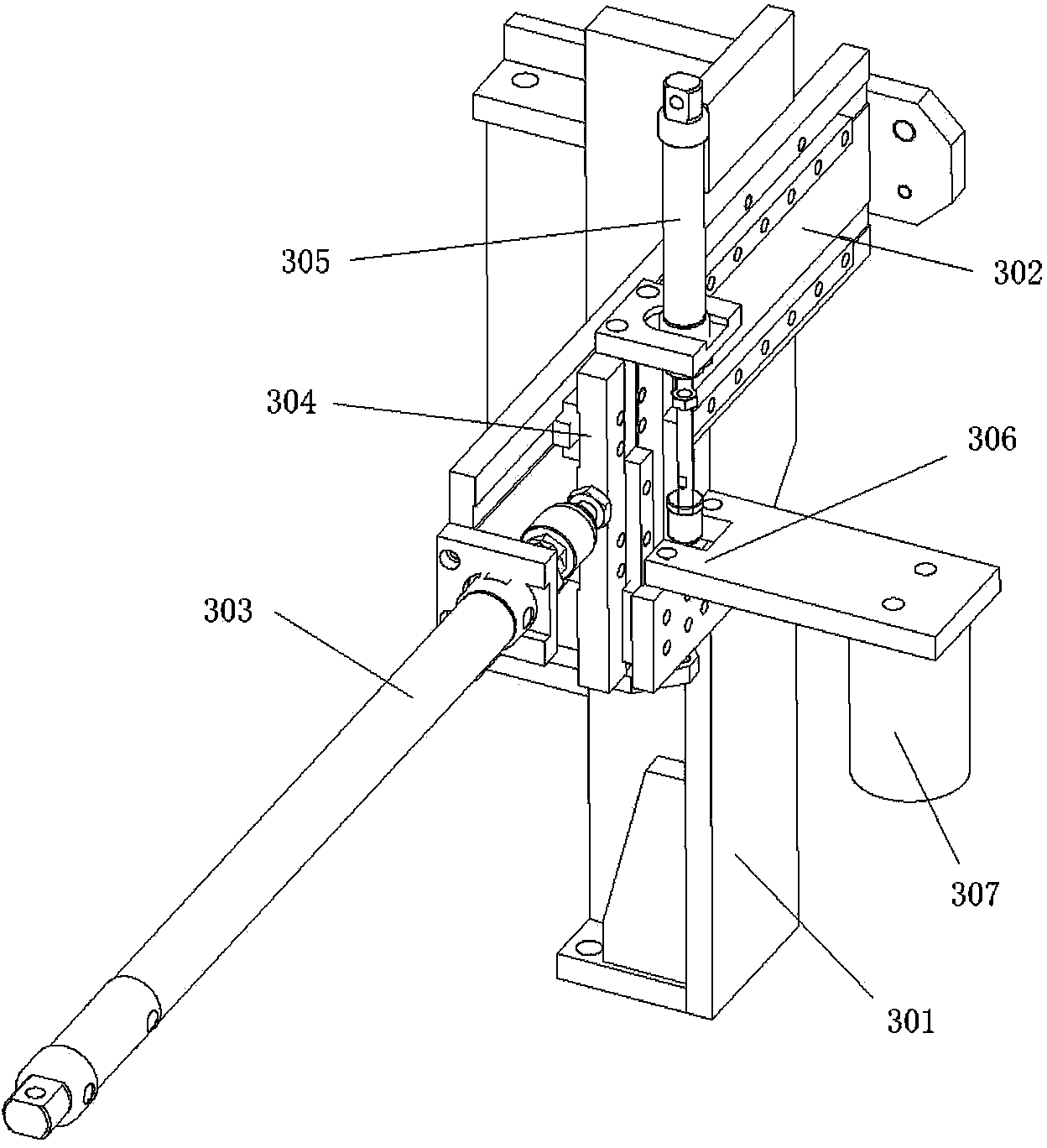

[0046] Reference Figure 1~Figure 10 , An automatic assembling machine for a light stand, comprising a frame 1, and a worktable 101 arranged on the frame. The worktable is provided with a multi-station turntable 102 driven to rotate by an indexing mechanism. The degree mechanism includes a cam divider and an indexing cylinder that drives the cam divider. The output end of the cam divider is connected to the multi-station turntable. The installation positioning mold 103 on the circumference, each of the installation positioning molds is evenly distributed with a plurality of installation positioning pillars 104 located on the same circumference, the lower end of the installation positioning pillar and the upper end surface of the installation positioning mold pass through a circle Arc transition

[0047] The upper chassis station 105, the upper connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com