A chemical washing system for treating heavy metal and organic pollution in soil

A chemical leaching and organic pollution technology, applied in the field of soil remediation, to prevent secondary pollution and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

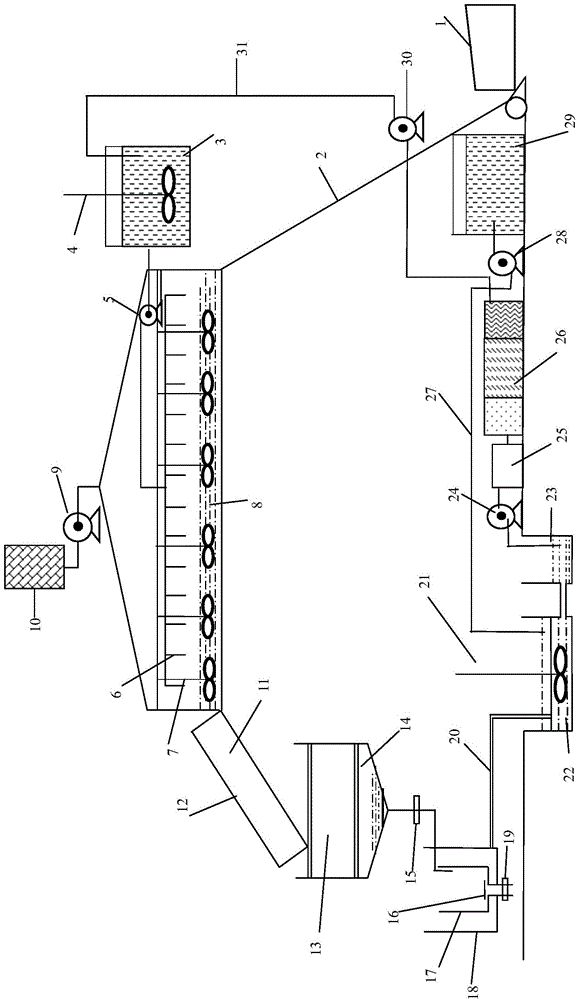

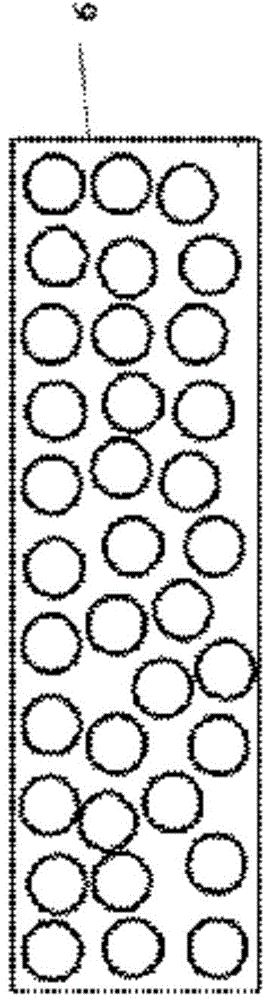

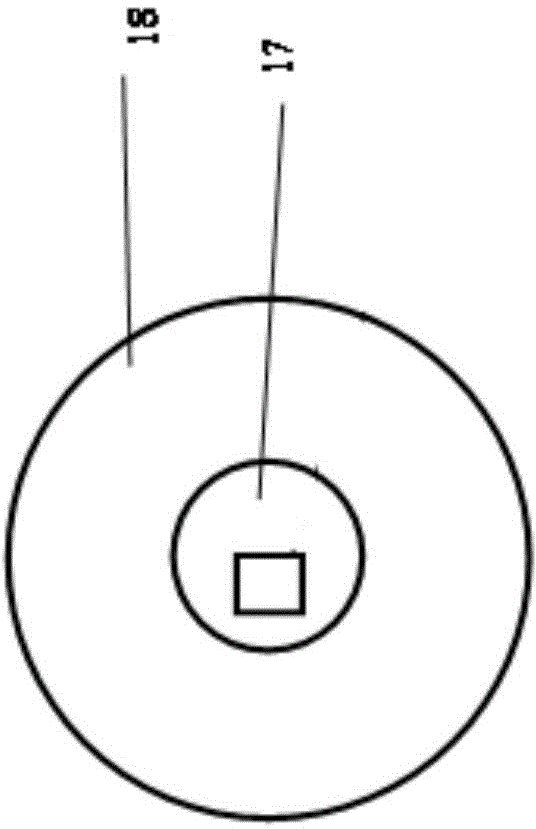

[0037] see figure 1 , a chemical leaching system for treating soil heavy metals and organic pollution, its composition includes: 1, soil crushing and screening equipment 2, upward conveyor belt 3, eluent preparation tank 4, mechanical stirring paddle 5, dosing high-pressure washing pump 6 , high-pressure spray system 7, suspended stirring paddle 8, vibrating conveyor belt 9, vacuum pump 10, exhaust activated carbon adsorption tank 11, downward conveyor belt 12, anti-splash baffle 13, mud-water separation tank 14, conical funnel box 15, the first On-off valve 16, automatic movable sieve plate 17, inner barrel body 18, outer barrel body 19, second on-off valve 20, leachate delivery pipeline 21, stirring paddle 22, coagulation tank 23, sedimentation tank 24, lift pump 25, Buffer tank 26, leachate filtration and adsorption equipment 27, coagulant delivery pipeline 28, dosing pump 29, coagulant storage tank 30, delivery pump 31, effluent delivery pipeline after leachate treatment. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap