An electronic fruit sorting machine

A fruit sorting and electronic technology, applied in the field of agricultural machinery, can solve the problems of low weighing and sorting accuracy and degree of automation, high work efficiency and high manufacturing cost, and achieve high weighing and sorting accuracy, high work efficiency, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

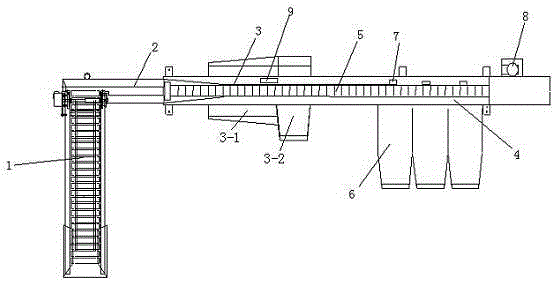

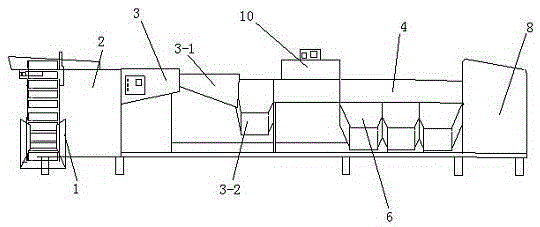

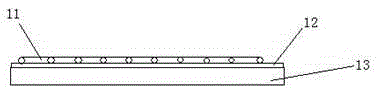

[0036] refer to Figure 1a , 1b, the present embodiment comprises a transmission mechanism, a hopper lifting device 1, a fruit discharge device 2 and a control system 10, and the hopper lifting device 1 is connected with a fruit discharge device 2, a primary sorting device 3, and a fine sorting device 4 in sequence, and the primary sorting device The selection device 1 is provided with an induction electronic scale 9, the two sides of the fine sorting device 4 are oppositely provided with a fruit puncher 7 and a fruit recovery device 6, the tail of the fine sorting device 4 is provided with a fruit tray correction device, and the preliminary sorting device 3 And fine sorting device 4 is provided with circulating chain 11, and circulating chain 11 is connected with transmission mechanism transmission mechanism with frequency conversion governor 8, and circulating chain 11 is provided with fruit plate 5, induction electronic scale 9, fruit beater 7 and frequency conversion regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com