Texture forming method of air-dried beef and mutton

A beef and mutton, dry matter technology, applied in the directions of food drying, food heat treatment, food preparation, etc., can solve the problems of restricting the source of raw materials and product types of air-dried beef and mutton products, unfavorable enterprise promotion, and high molding costs, so as to save production costs. , easy to cut strips, reduce the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, vacuum stirring pickling and non-vacuum stirring pickling verification

[0052]Thaw chunks of frozen beef at -2°C to 0°C, trim off the visible fat and fascia on the surface, put it into a meat grinder, pass through an 8mm orifice plate and grind it into minced meat, and then divide the minced meat into two parts equally. Put a part into the vacuum mixer, add auxiliary materials in batches, stir for 2 minutes in the forward direction, and then stir in the reverse direction for 2 minutes, evenly put in 3‰ transglutaminase (150U / kg raw meat), vacuumize until the vacuum degree reaches 0.06 Above MPa, rotate forward for 4 minutes, reverse for 4 minutes, and cycle once. A total of 16 minutes of vacuum stirring at a speed of 22 rpm. Put the other part of minced meat into the non-vacuum mixer, add the auxiliary materials in batches, stir for 2 minutes in the forward direction, and then reverse the stirring for 2 minutes, evenly add 3‰ transglutaminase (150U / kg raw...

Embodiment 2

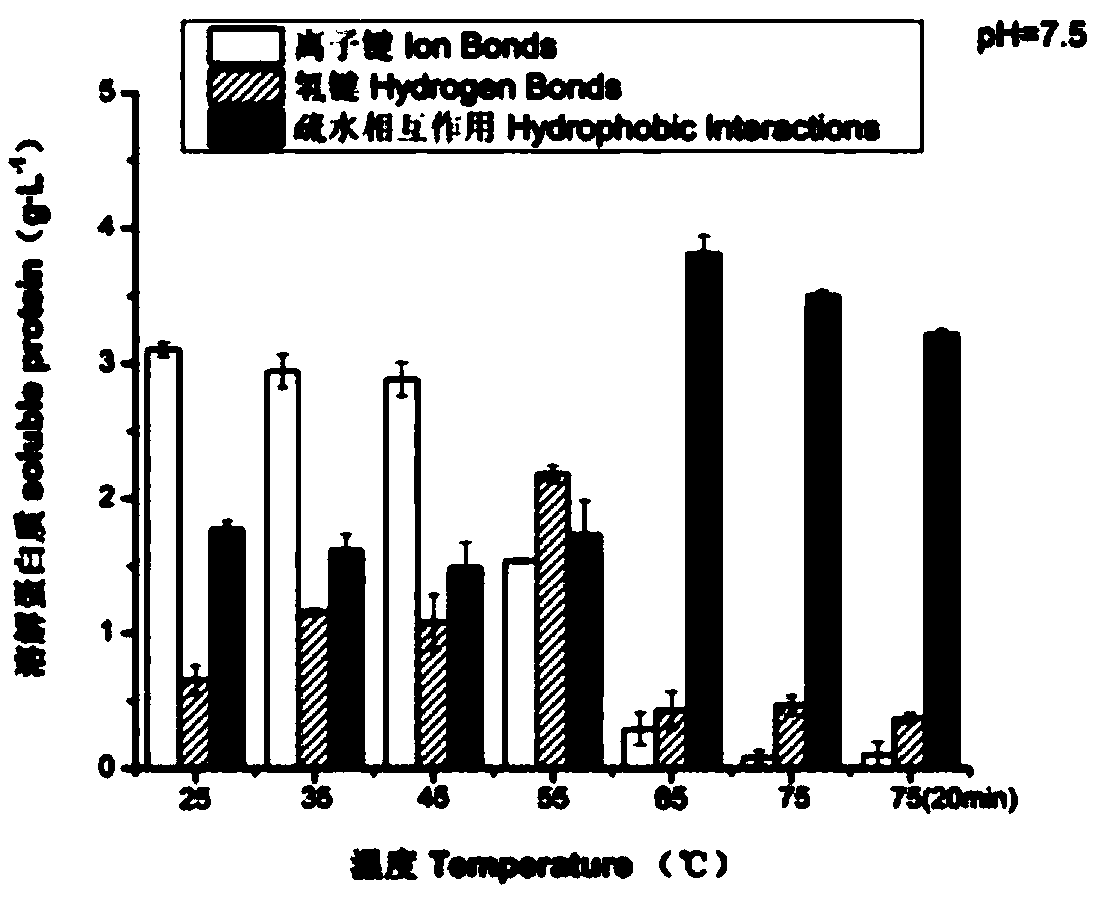

[0056] Example 2. Validation of Muscle Gradient-variable Temperature Air-drying Effect

[0057] Mutton myofibrillar protein was dissolved in 50mM phosphate buffer (pH6.0) containing 0.6M NaCl, and the protein concentration was adjusted to 30mg·mL -1 . Use 1M NaOH or HCl to adjust the system to the pH value required for the test, and heat it in a water bath after dispensing. -1 The temperature was raised linearly to 75°C and held for 20 minutes. During the heating process, the molecular force was studied for gels at 25°C, 35°C, 45°C, 55°C, 65°C, and 75°C. In addition, differential scanning calorimeter (DSC) was used to analyze the thermal stability of lamb myofibrillar protein under different pH value systems. The test conditions of DSC were that the temperature scanning range was 25°C to 100°C, and the heating rate was 5°C. min -1 , use the Q20 empty aluminum box as a blank control, and use the software that comes with the instrument to analyze the thermal denaturation temp...

Embodiment 3

[0066] Embodiment 3, the preparation method of air-dried mutton with peanuts

[0067] 1) Select 100kg of frozen mutton hind legs, remove obvious fat and fascia, and thaw at 2-4°C;

[0068] 2) Put the thawed mutton pieces into a meat grinder and pass through an 8nrn orifice plate to obtain minced meat;

[0069] 3) Put the minced mutton into the vacuum mixer, add the auxiliary materials in batches, stir for 2 minutes in the forward direction, and then reverse the stirring for 2 minutes, and evenly add 3‰ of transglutaminase (150U / kg raw meat) . Vacuumize until the vacuum degree reaches above 0.06MPa, rotate forward for 4 minutes, reverse for 4 minutes, and cycle once, a total of 16 minutes of vacuum stirring, the speed is 22 rpm;

[0070] The auxiliary materials are: 10kg crushed peanuts, 1.1kg salt, 0.12kg chicken essence, 0.1kg monosodium glutamate, 0.1kg soft white sugar, 0.2kg beef paste, 0.1kg chicken paste, 0.15kg dark soy sauce, 0.15kg light soy sauce, marinated sea mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com