Nanocomposite precursor solution obtained from solution, method of making thin film and thin film made therefrom

A precursor solution, solution technology, applied in metal material coating process, conductive coating, final product manufacturing, etc., can solve problems such as difficulty in maintaining dynamic wetting lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach (1)

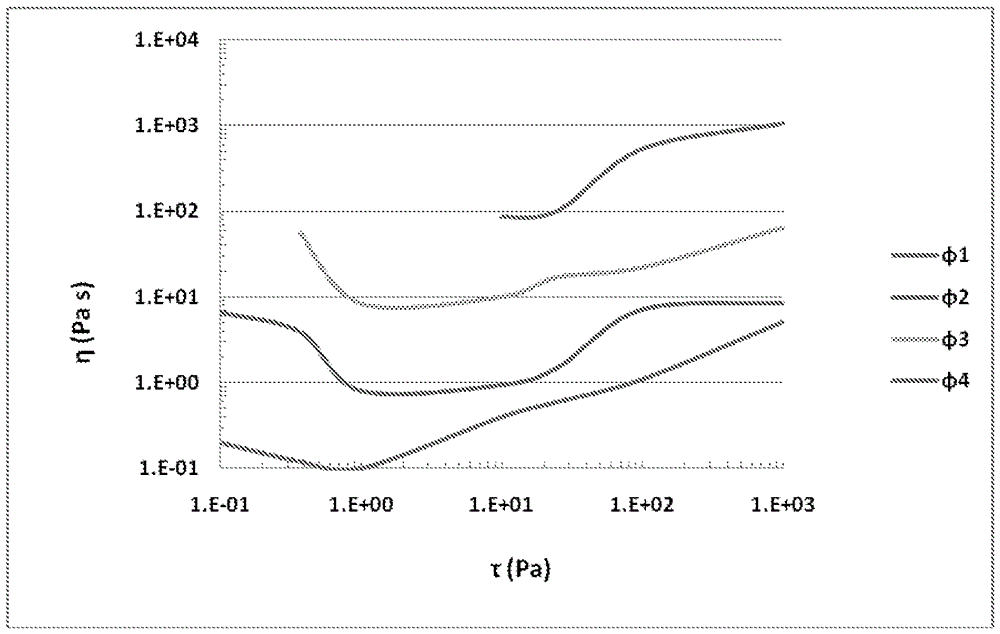

[0086] Implementation plan (1): The preferred precursor solution comprises one or more, preferably two or more sol-gel metal precursors and / or sol-gel metalloid precursors, one or more polar protic solvents and a One or more polar aprotic solvents, wherein the precursor solution forms a gel after applying a shear force to the precursor solution.

Embodiment approach (2)

[0087] Implementation plan (2): The preferred precursor solution above, wherein the viscosity of the solution increases with increasing shear force.

Embodiment approach (3)

[0088] Implementation plan (3): The preferred precursor solution above, wherein the metal in the one or more sol-gel metal precursors is selected from the group consisting of transition metals, lanthanide metals, actinide metals, alkaline earth metals, and Group IIIA to Group VA metals group, any subset of said group, or any combination of members of said group or a subset of said group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear load | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com