High-power MOSFET driving circuit

A drive circuit, high-power technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of fixed dead time, faster turn-on and turn-off time, high cost, etc. The effect of breaking speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

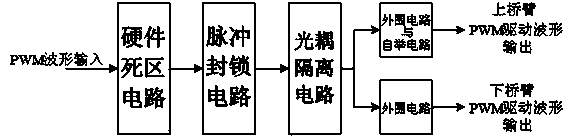

[0011] Such as figure 1 As shown, the system schematic diagram of the high-power Mosfet driving circuit is composed of a hardware dead zone circuit, a pulse blocking circuit, an optocoupler isolation circuit, peripheral circuits and a bootstrap circuit. Among them, the hardware dead zone circuit generates the hardware dead zone time, and the pulse blockade circuit is used to block the pulse signal when the protection state occurs. To drive high power Mosfet.

[0012] Such as figure 2 The circuit diagram of the high-power Mosfet driving circuit is shown, the dead zone circuit includes an inverter, two RC charging and discharging circuits, two NAND gates, the PWM signal input is connected to the input terminal of the NAND gate U1A, and the NAND gate U1A 1A The other input terminal is connected to the RC charging and discharging circuit to obtain the PWM1 driving signal, and at the same time, the PWM signal input is connected to the input terminal of the NAND gate U1B through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com