Solar cell module aluminum frame assembly machine

A technology for solar cells and assembly machines, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of easy dislocation of aluminum frame, increase defective rate, high dynamic strength, etc., to improve working conditions, eliminate broken Poor, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

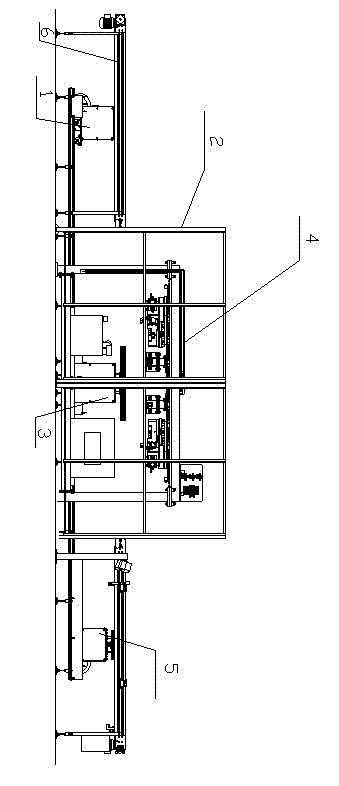

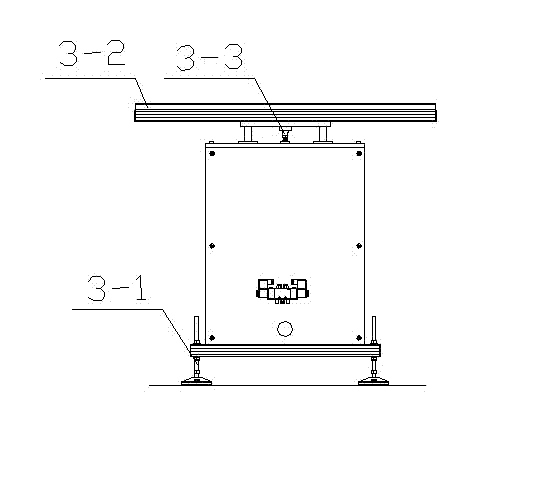

[0021] refer to Figure 1-5 , this specific embodiment adopts the following technical solutions: it includes a pre-assembled frame unit 1, a safety fence 2, a lifting table 3, a frame pressing angle unit 4, a component loading unit 5 and a component loading unit 6, and the safety fence 2 A component loading unit 6 is set on one side of the component loading unit 6, and a pre-framing unit 1 is set under the component loading unit 6. One end of the pre-framing unit 1 is connected to one end of the component loading unit 5, and the middle position of the two safety fences 2 An elevating platform 3 is provided, and a group frame crimping unit 4 is arranged above the elevating platform 3 .

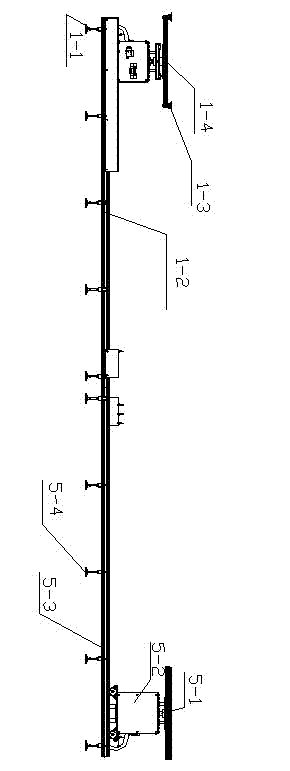

[0022] The pre-group frame unit 1 includes a first level adjustment foot 1-1, a guide rail 1-2, a vacuum device 1-3 and a pre-group frame 1-4, and a vacuum device 1 is provided at both ends of the pre-group frame 1-4 -3, a first guide rail 1-2 is designed on the lower side of the pre-group fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com