A free-winding optical fiber current sensor sensitive coil and manufacturing method

A technology of optical fiber current and sensitive coils, applied in the direction of measuring current/voltage, instruments, measuring electrical variables, etc., can solve the problems of unfavorable transportation and installation, no variable shape, etc., and achieve space saving, easy transportation, and tensile strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

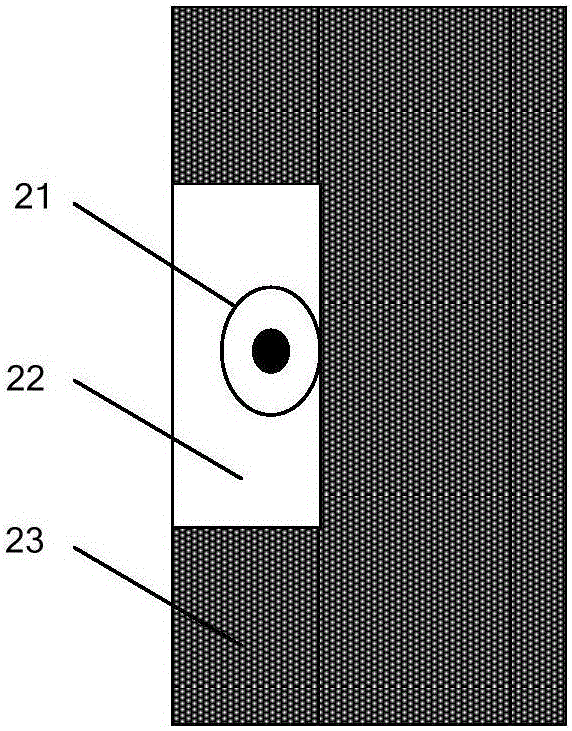

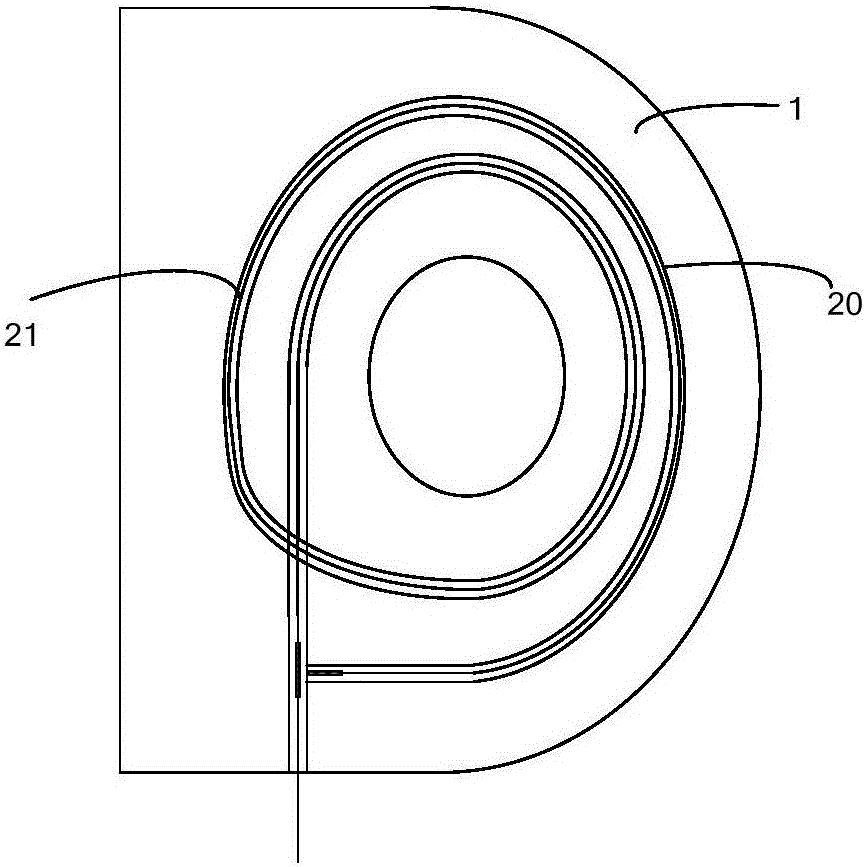

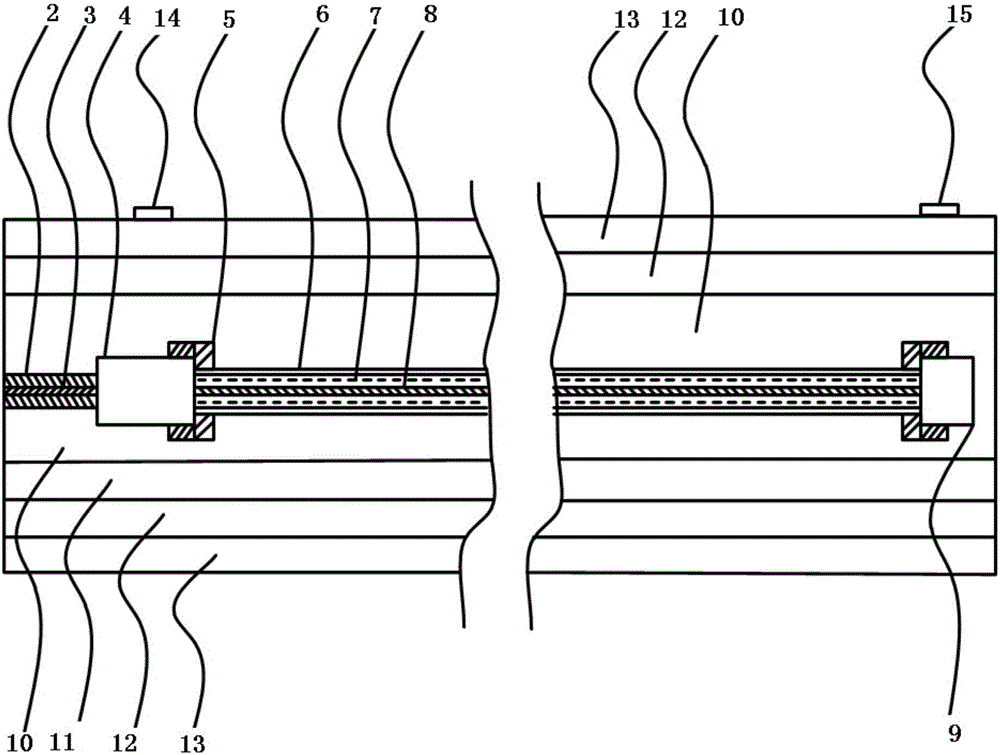

[0034] Such as image 3 , 4 As shown, the sensitive coil of the optical fiber current sensor of the present invention includes an optical path main body composed of a polarization maintaining optical fiber 3, a λ / 4 wave plate 4, a sensitive optical fiber 8 and a reflector 9, an optical fiber protective sleeve 2, a capillary 6, a reinforced plastic matrix 11, an inner The sheath 12 and the outer sheath 13, wherein the polarization-maintaining optical fiber 3 is protected by the optical fiber protective sheath 2, the sensitive optical fiber 8 is covered with a capillary 6, the capillary 6 is filled with a lubricant 7, and the ports at both ends of the capillary 6 are sealed by the colloid 5, The two ends of the sensitive optical fiber 8 are respectively connected to one end of the λ / 4 wave plate 4 and the mirror 9, the other end of the λ / 4 wave plate 4 is connected to the polarization-maintaining optical fiber 3, and the main body of the optical path is fixed in the reinforced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com