Precise Control of Waste Heat Utilization High Efficiency Clean Room Constant Temperature and Humidity Air Conditioning Unit

A technology for precise control and air-conditioning device, applied in the field of air-conditioning device, which can solve the problems of consumption, large refrigeration load, and inability to fully meet the needs of energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

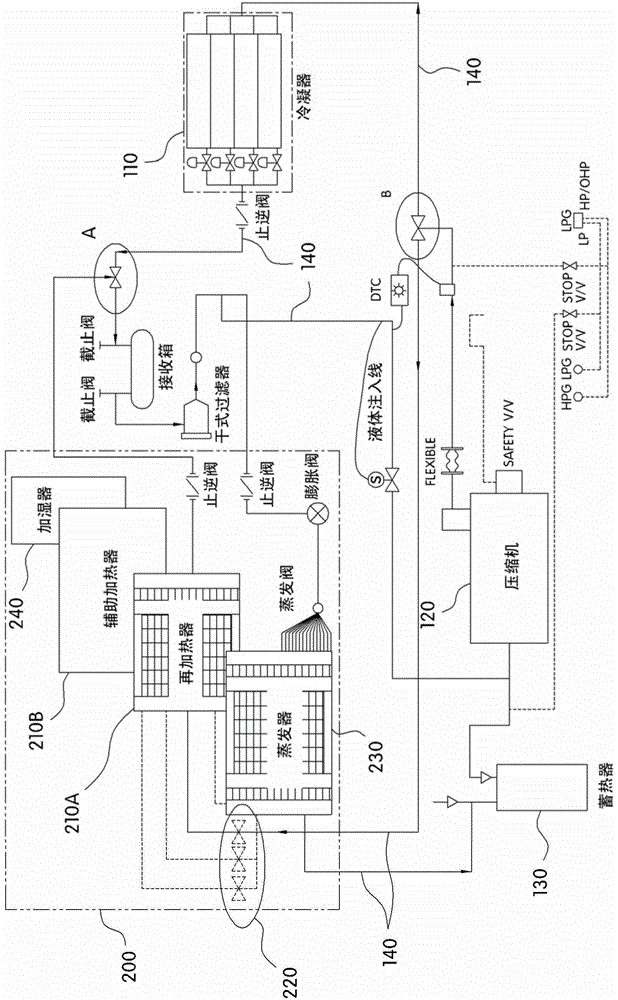

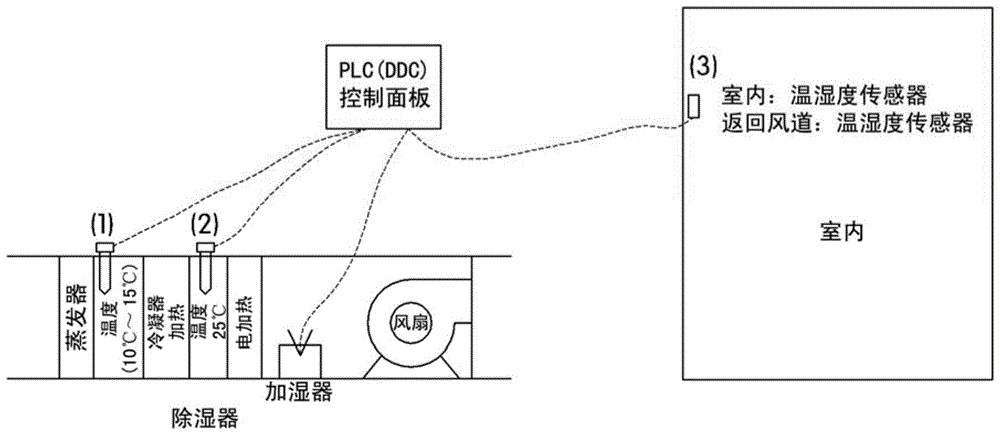

[0014] Regarding the above objects and advantages of the present invention, those skilled in the art can more clearly understand the preferred embodiments of the present invention described below with reference to the accompanying drawings.

[0015] First of all, the technical idea adopted in the present invention is explained. In the process of dehumidification due to the high humidity of the outside air in summer, the temperature drops due to supercooling, so reheating is required, and more heat energy will be consumed at this time. The existing While conventional air conditioners discharge the waste heat of the outdoor unit generated when cooling the air to the atmosphere, the present invention aims to recover the waste heat discharged to the atmosphere and adjust the humidity without supplying additional energy equivalent to the energy of the waste heat.

[0016] In addition, the present invention expects the additional effect of compensating for the supercooled temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com