Labyrinth sealing device

A technology of labyrinth seals and sealing devices, which is applied in the direction of engine seals, furnaces, engine components, etc., to achieve the effects of reasonable design, good high temperature resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

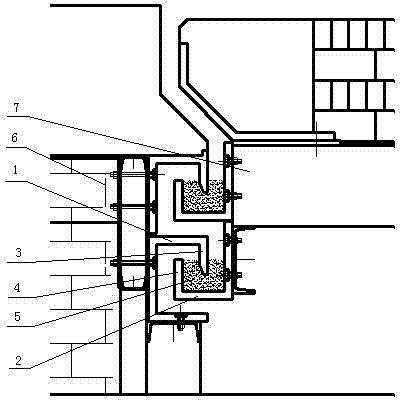

[0016] Such as figure 1 As shown, this embodiment provides a labyrinth sealing device, including a sealing track 1 and a guide track 2, both of which are concave tracks, and the notch direction of the sealing track 1 is in line with the guiding track 2. The direction of the notch of the track 2 is opposite, the side wall 3 of the guide track 2 is arranged in the concave groove of the sealing track 1, and the side wall 3 4 of the sealing track 1 is arranged in the concave groove of the guide track 2 Inside, the guide track 2 is filled with sealant 5, the sealant 5 is sand, the seal track 1 is fixed on the furnace body 6, the guide track 2 is fixed on the trolley 7, and the trolley Both sides of 7 are provided with two groups of sealing devices.

[0017] This embodiment is a kind of labyrinth sealing device, through the side wall 3 of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com