Device for removing rock debris in hole through waterpower

A cuttings and hydraulic technology, which is applied in the field of hydraulic removal of cuttings in the hole, achieves good market prospects, does not occupy the ground area, and has good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

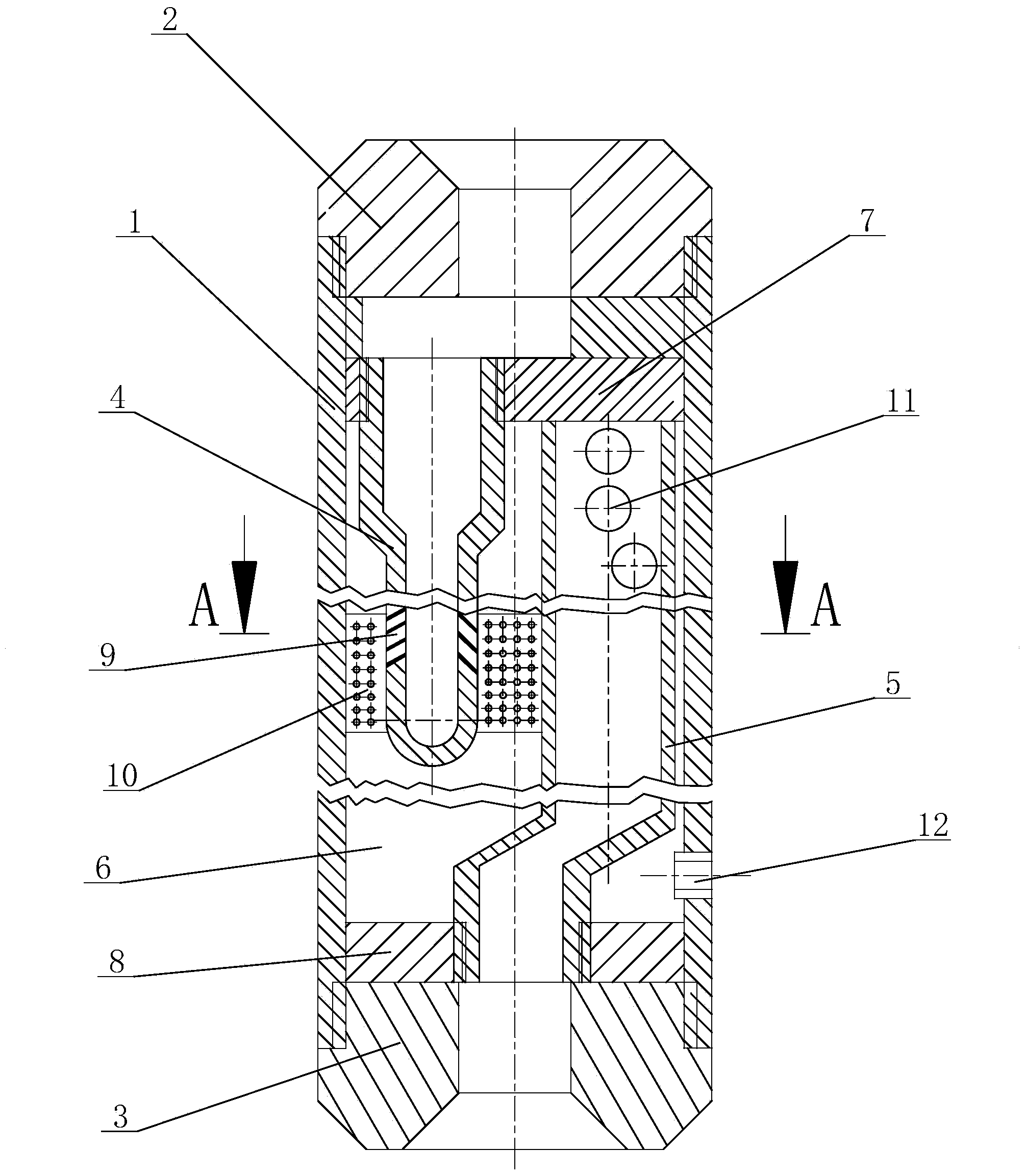

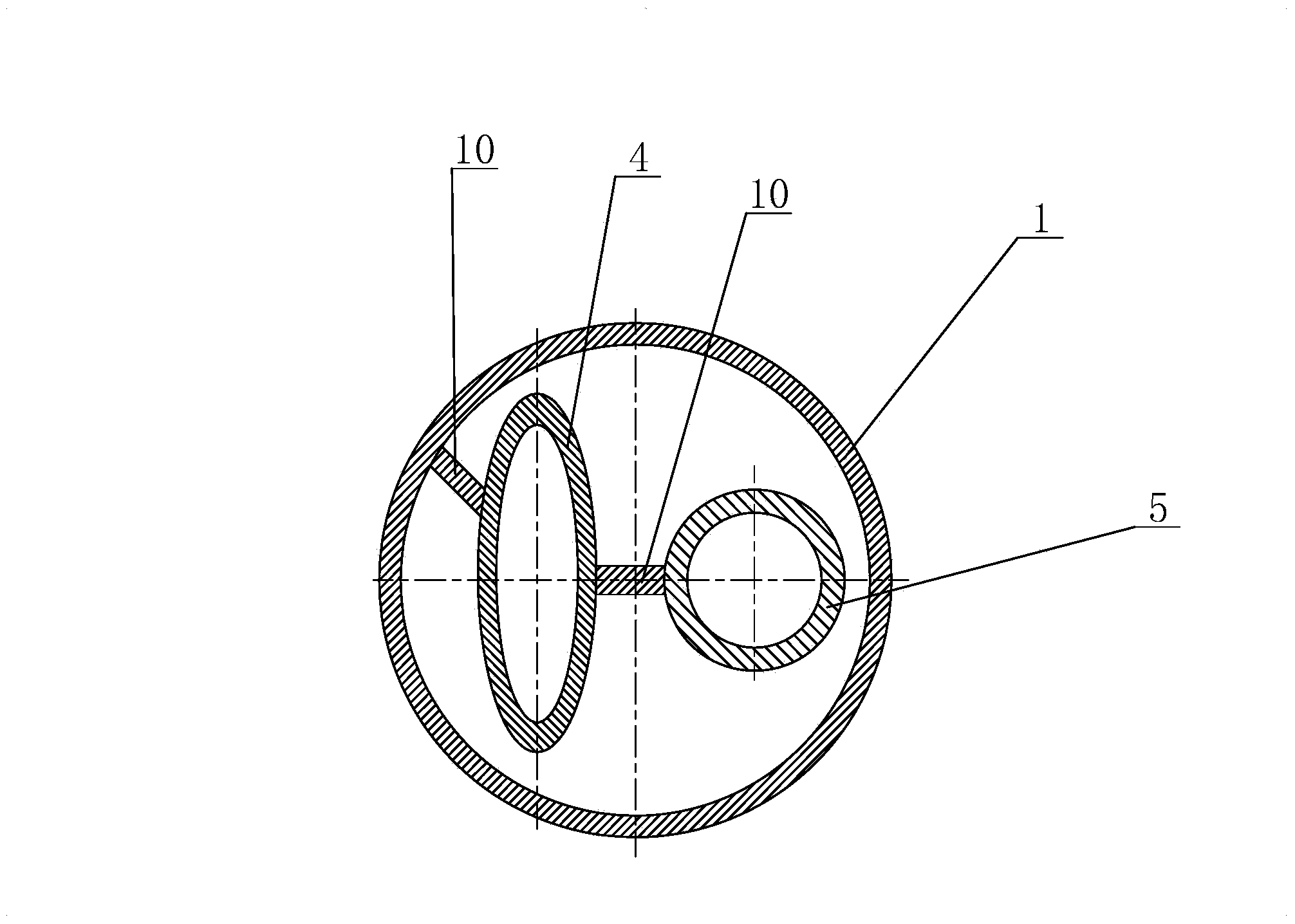

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0016] Please refer to figure 1 and figure 2 As shown, in this embodiment, a hydraulic debris removal device in the hole is arranged under the active drill pipe, including a casing 1, an upper joint 2, a lower joint 3, an inlet pipe 4 and an outlet pipe 5, and the outer casing 1 is a cylinder One end of the upper joint 2 is connected to the upper end of the shell 1 through a nut, and the other end is connected to the lower part of the active drill pipe. One end of the lower joint 3 is connected to the lower end of the shell 1 through a nut, and the other end is connected to the drill pipe. A cuttings holding chamber 6 is formed between the upper joint 2 and the lower joint 3 in the housing 1, the inlet pipe 4 is connected to the bottom of the upper joint 2 in the housing 1 through the upper flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com