High temperature resistant and aging resistant chloroprene rubber composition

A chloroprene rubber and composition technology is applied in the field of chloroprene rubber compositions for automobiles, and can solve the problems of poor heat-resistant air aging performance, aging, and high cost of silica gel and acrylate rubber

Inactive Publication Date: 2014-04-09

TIANJIN PENGYI GRP CO LTD

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is mainly to provide a neoprene composition resistant to hot air aging, to solve the problem of poor heat aging resistance of neoprene rubber and high cost of silica gel and acrylic rubber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

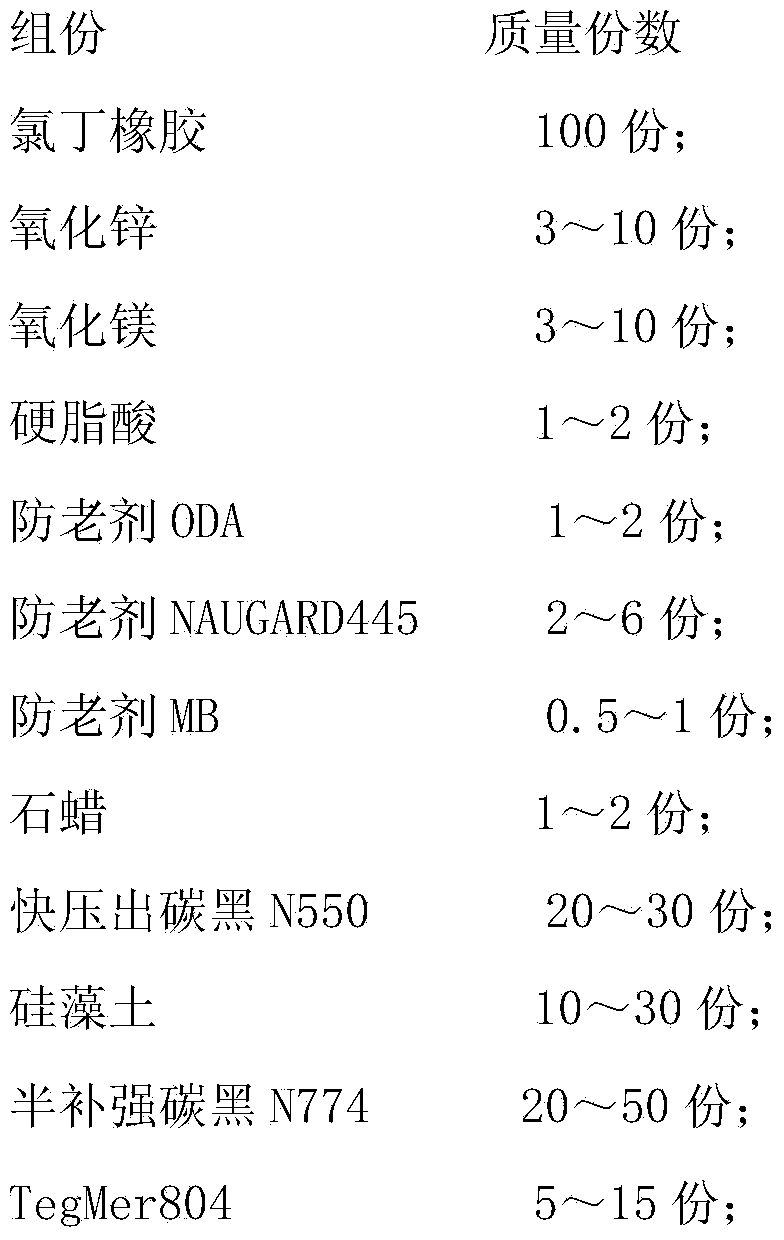

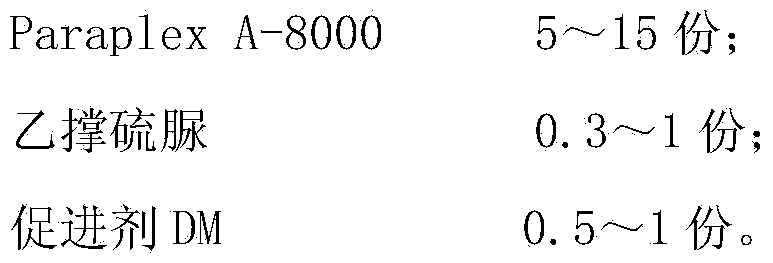

Embodiment 1

[0015]

[0016]

[0017] Prepare rubber test piece test performance as follows by above-mentioned example:

[0018]

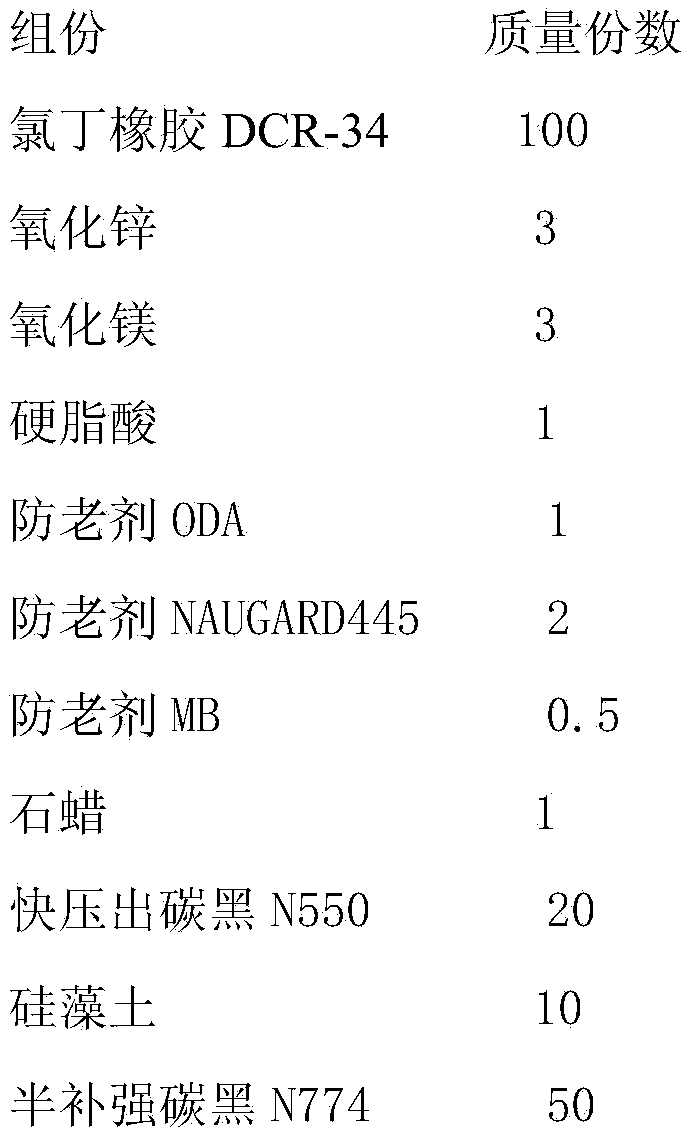

Embodiment 2

[0020]

[0021]

[0022] Prepare rubber test piece test performance as follows by above-mentioned example:

[0023]

Embodiment 3

[0025]

[0026]

[0027] Prepare rubber test piece test performance as follows by above-mentioned example:

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a high temperature resistant and aging resistant chloroprene rubber composition. The high temperature resistant and aging resistant chloroprene rubber composition comprises the following components: chloroprene rubber, zinc oxide, magnesium oxide, stearic acid, an anti-aging agent ODA, an anti-aging agent NAUGARD445, an anti-aging agent MB, paraffin, fast extruding carbon black N550, diatomaceous earth, semi-reinforcing carbon black N774, TegMer804, Paraplex A-8000, ethylene thiourea and an accelerant DM. By virtue of contrastive analysis of chloroprene rubber formula experiment, the formula performance can fully meet the standard requirement, the hot air aging resistance is prior to that of the traditional chloroprene rubber formula, and good performances can be preserved under the hot air environment of 125 DEG C. Intercooler rubber tubes are produced by using the chloroprene rubber formula so as to ensure normal use in an automobile of a turbocharging system; the performances of chloroprene rubber products are improved, so that the service life of the automobile is ensured, and the cost of the turbocharging system is reduced.

Description

technical field [0001] The invention relates to the technical field of rubber formulations, in particular to neoprene rubber compositions for automobiles. Background technique [0002] With the development of the automobile industry, turbochargers are more and more widely used in automobiles. Since the turbocharger provides higher power to the car, the rubber hose connecting the intercooler in the turbocharger system is usually made of silicone or acrylic rubber. Since the air temperature at the inlet end of the intercooler is relatively high, it is necessary to use silicone or acrylic rubber with good heat resistance. The price cost of the rubber hose of the material is relatively high. However, ordinary neoprene materials are usually used at a temperature of 100°C, which cannot meet the long-term use in an environment of 125°C. Therefore, to use chloroprene rubber for the hose at the air outlet of the intercooler to reduce the cost, the high temperature aging resistance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L11/00C08K13/02C08K3/04C08K3/34C08K3/22C08K5/09C08K5/405

Inventor 张洪起王金财

Owner TIANJIN PENGYI GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com