Application of reverse osmosis desalination technology to production equipment for distilled water

A production device and distilled water technology, applied in the direction of osmosis/dialysis water/sewage treatment, general water supply saving, oxidized water/sewage treatment, etc., can solve problems such as increasing energy consumption, reducing water production, affecting heat transfer efficiency, etc., to achieve operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

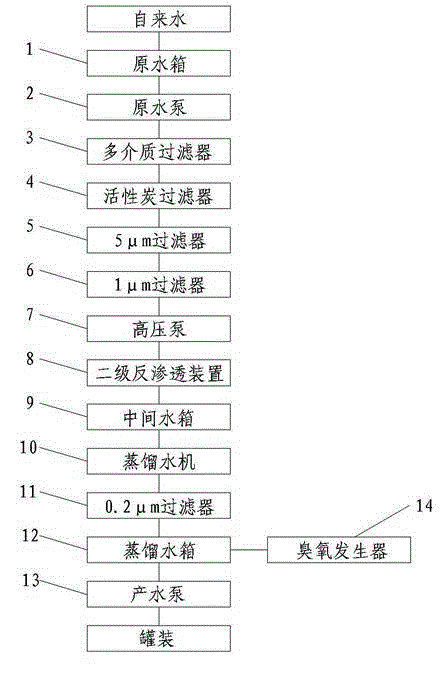

[0030] Such as figure 1 As shown, the reverse osmosis desalination technology is applied to the production device for preparing distilled water, which includes a raw water tank 1, a raw water pump 2, a multimedia filter 3, an activated carbon filter 4, a 5 μm filter 5, a 1 μm filter 6, and a high-pressure Pump 7, secondary reverse osmosis device 8, intermediate water tank 9, distilled water machine 10, 0.2 μm filter 11, distilled water tank 12, produced water pump 13;

[0031] The tap water is delivered to the raw water tank 1, and the raw water tank 1 adopts an aeration process to reduce the depth of residual chlorine in the tap water. When in use, detect the residual chlorine and pH value of the tap water in the raw water tank 1 once a day to ensure that the residual chlorine in the tap water is ≤0.8mg / L and the pH value is 6.5-8.5; detect the microorganisms once a week to ensure that the total number of colonies in the tap water is ≤100cfu / mL, coliform bacteria ≤3MPN / mL. ...

Embodiment 2

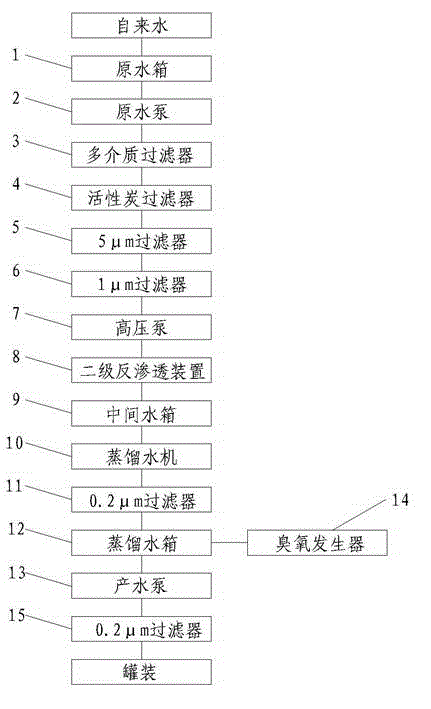

[0039] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a 0.2 μm filter 15, which is connected to the produced water pump 13; the distilled water is filtered through the 0.2 μm filter 15, and then filling. The 0.2 μm filter 15 removes particles larger than 0.2 μm in the water to improve the cleanliness of the water. The water pressure difference between the inlet and outlet of the 0.2 μm filter 15 should be greater than 10Psi.

[0040] Features that are not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

[0041] The various indexes of the distilled water prepared by Embodiment 1 and Embodiment 2 of the present invention are inspected, and the inspection results are shown in Table 1.

[0042] Table 1

[0043] .

[0044] As can be seen from Table 1, the quality of the distilled water prepared by the present invention is good, and each test index is all qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com