Clamp hoisting device

A lifting and clamping technology, applied in the direction of load hoisting elements, transportation and packaging, can solve the problems of inability to use ropes and cranes that cannot be transported, and achieve improved applicability and scope of application, simple structure, and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The process embodiment will be described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

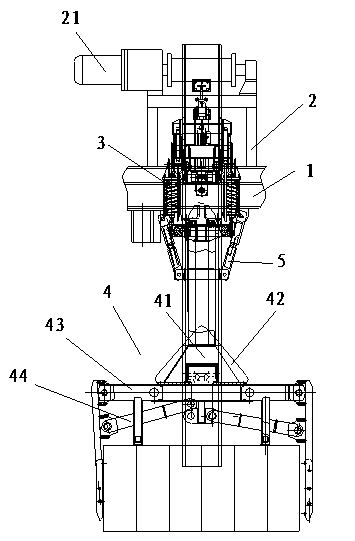

[0018] Such as figure 1 As shown in the schematic diagram of the structure of the present invention, a clamp lifting device includes a body 1, a mounting frame 2 fixedly installed on the body 1, a motor 21 fixedly mounted on the top of the mounting frame 2, and a motor 21 fixed on the top of the mounting frame 2. The clamp 4 of the main body 1 and the cylinder 5 fixedly mounted on the main body 1 and driving the clamp 4, the clamp 4 includes a fixed frame 41, a control rod 42 rotatably mounted on the mounting frame 2, a rotatably mounted There are two clamping jaws 43 on the fixed frame 41 and fixedly connected to the rotating end of the control rod 42 , and the rotating installation points are the same point.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com