Storing and distributing integrated process and system based on tray storage three-dimensional bank

A technology of three-dimensional warehouses and pallets, applied in storage devices, transportation and packaging, etc., can solve problems such as low operating efficiency, increased logistics links, and slow response, so as to improve operating efficiency, reduce floor space, and reduce equipment energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

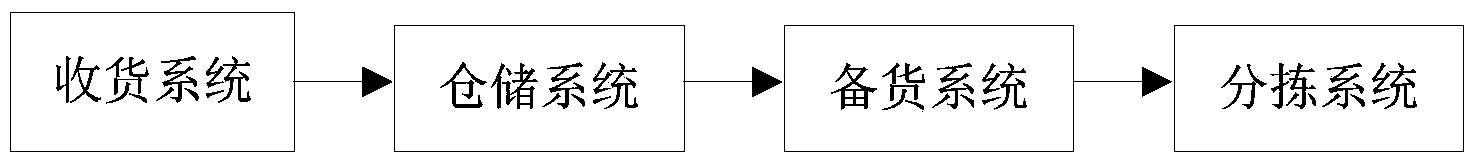

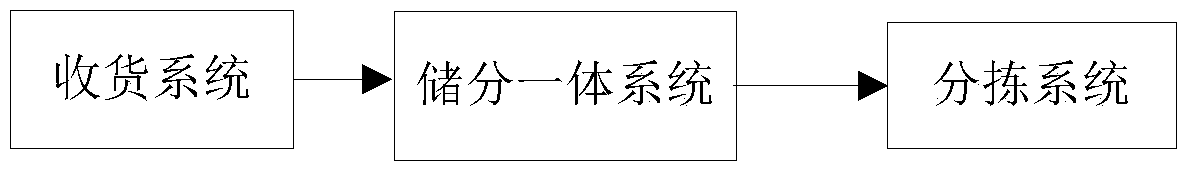

[0024] image 3 Shown is the composition diagram of the system of the present invention. Through the process layout, the storage system and the stocking system are effectively integrated to form an integrated system of storage and distribution, reducing the operation process. The whole system consists of a receiving system, a storage and distribution system, and a sorting system.

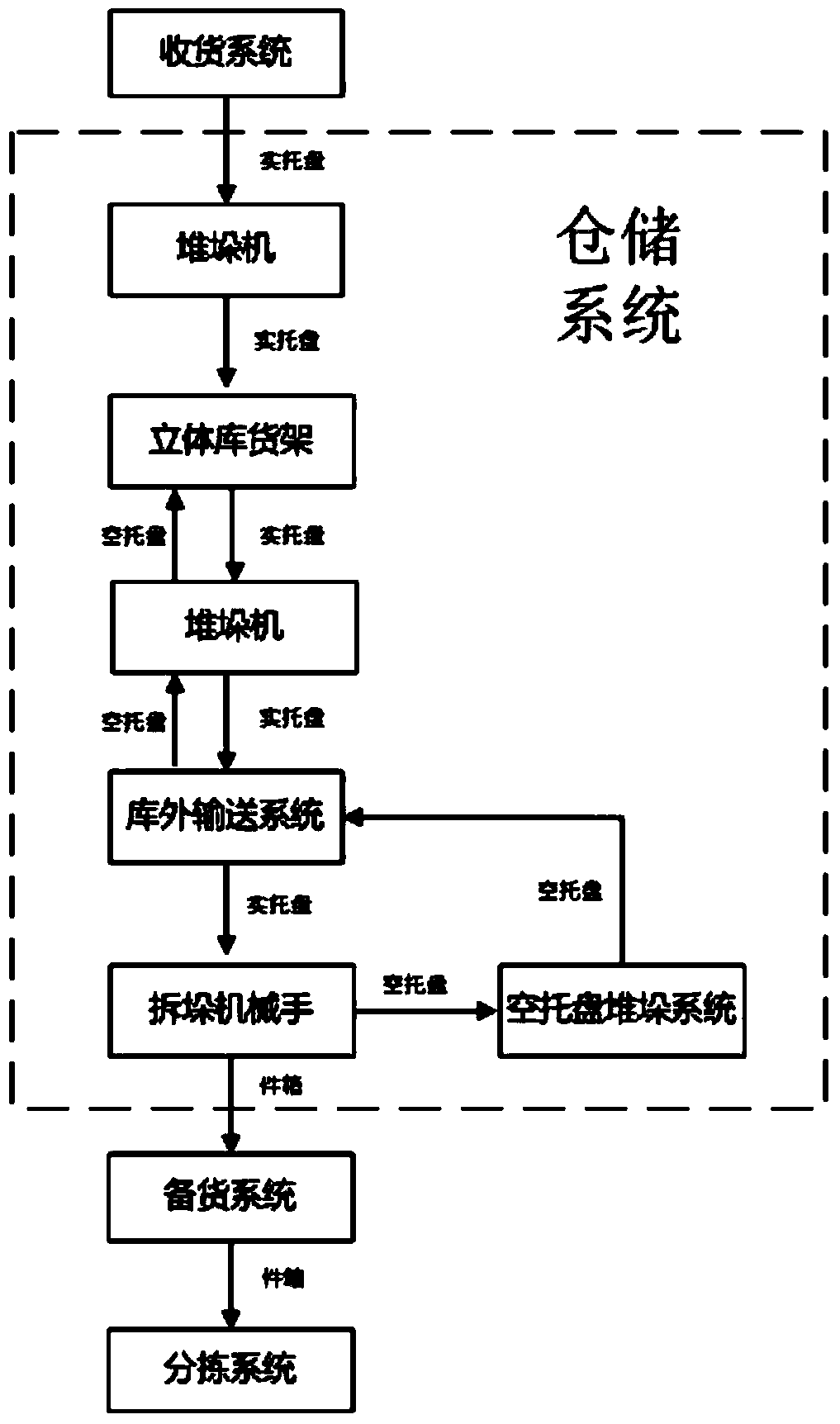

[0025] Figure 4 Shown is the process flow chart of the present invention. The materials are stacked on the pallet in the form of pieces to form a solid pallet. The solid pallets are put into the warehouse through the receiving system, and are automatically stored on the multi-layer beam-type shelves in the three-dimensional warehouse by the stacker. When the actual pallet needs to go out of the warehouse, the stacker will send the actual pallet to the integrated storage and separation station in the shelf, and the unstacking manipulator configured by the storage and separation integrated station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com