Toppled type garbage transfer box with tilting overhead door

A transfer box, dumping technology, applied in trash cans, garbage collection, household appliances, etc., can solve the problems of garbage can not be completely dumped, increase cleaning costs, garbage fermentation and other problems, achieve convenient daily maintenance and maintenance, reduce labor Strength, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below with reference to the drawings.

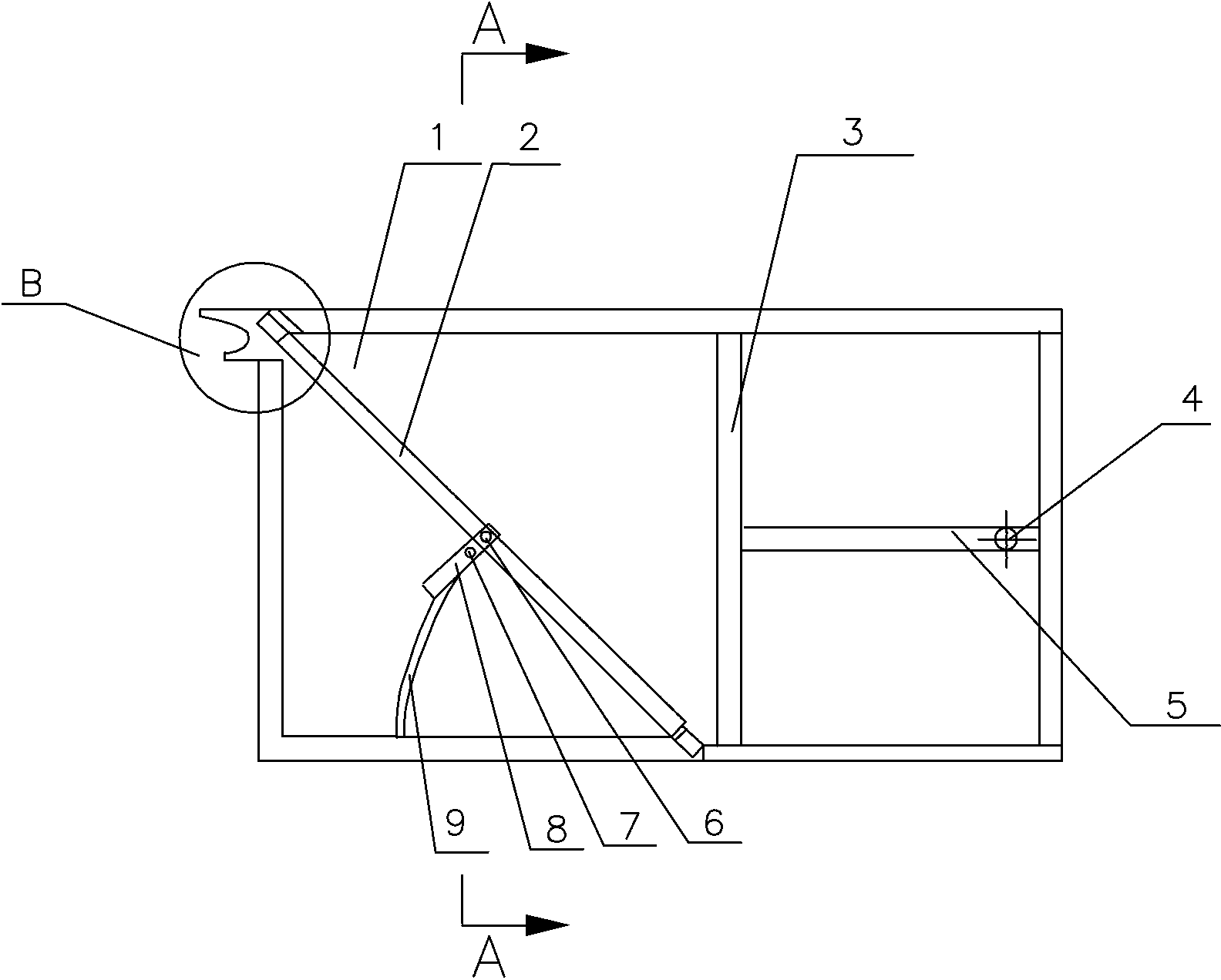

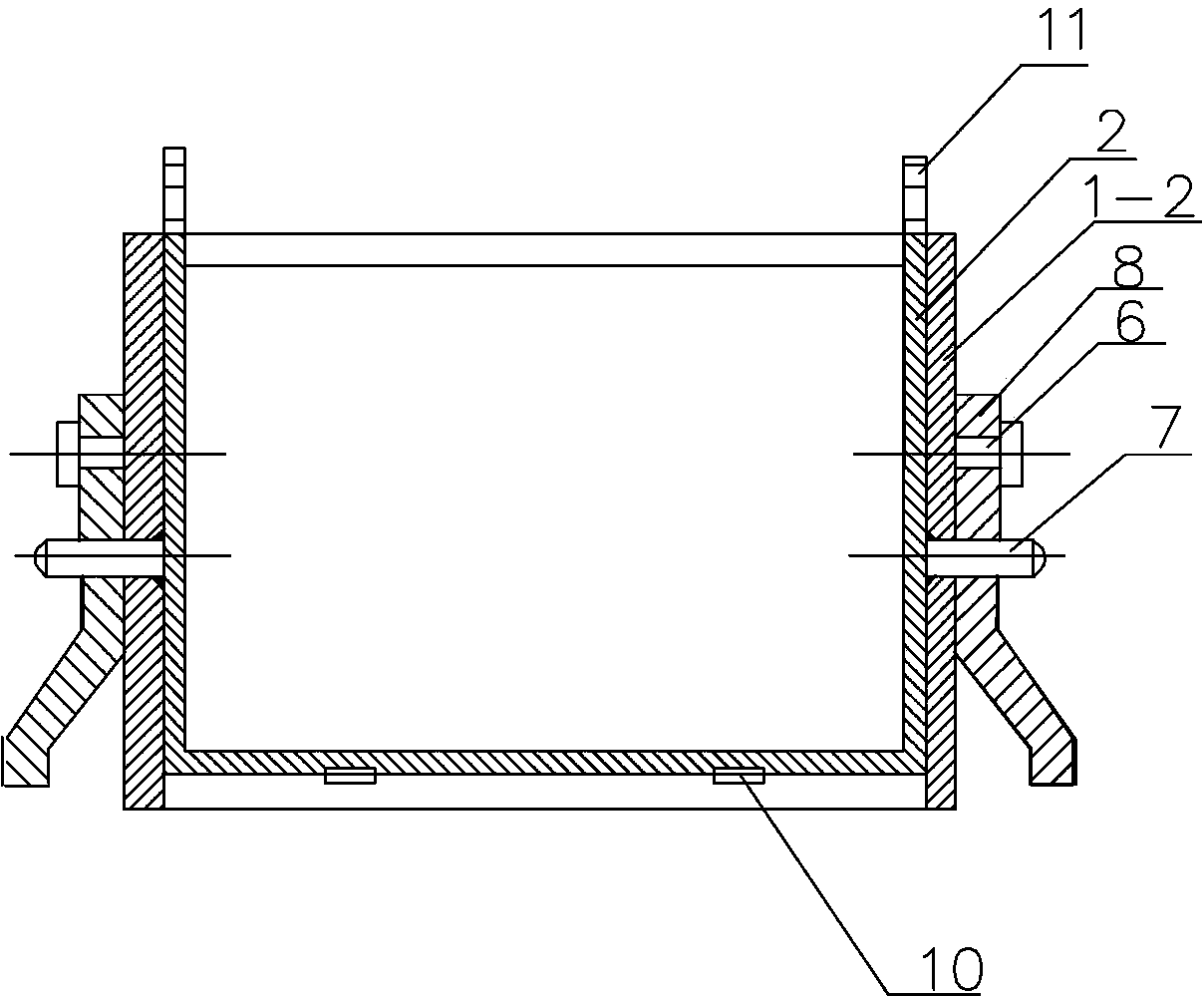

[0019] Such as Figure 1-4 As shown, the dumping tilting door garbage transfer box of the present invention includes a garbage transfer box body 1, a beam 5 and a column 3 arranged on the frame of the garbage transfer box body 1, and a lifting shaft 4 arranged on the beam 5, The sliding upper cover arranged on the top of the box body is characterized in that an inclined flap door mechanism is provided at the front end of the garbage transfer box body. The inclined flap door mechanism includes the inclined flap door 2, which is welded to the upper part of the inclined flap door frame. The card plate 11 is provided with a gusset locking shaft 7 in the middle part of the frame of the oblique flap door, and a gusset locking gusset 8 and a gusset rotation shaft are respectively provided on the vertical plates 1-2 on both sides of the garbage transfer box body 6. The locking gusset 8 of the oblique ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com