Automatic precise assembling platform for fusion target key components

An assembly platform, fusion target technology, applied in workpiece clamping devices, assembly machines, metal processing equipment, etc., can solve the problems of complex assembly process, redundant degrees of freedom, poor stability, etc., to improve assembly accuracy and efficiency, The effect of reducing system complexity, increasing rigidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

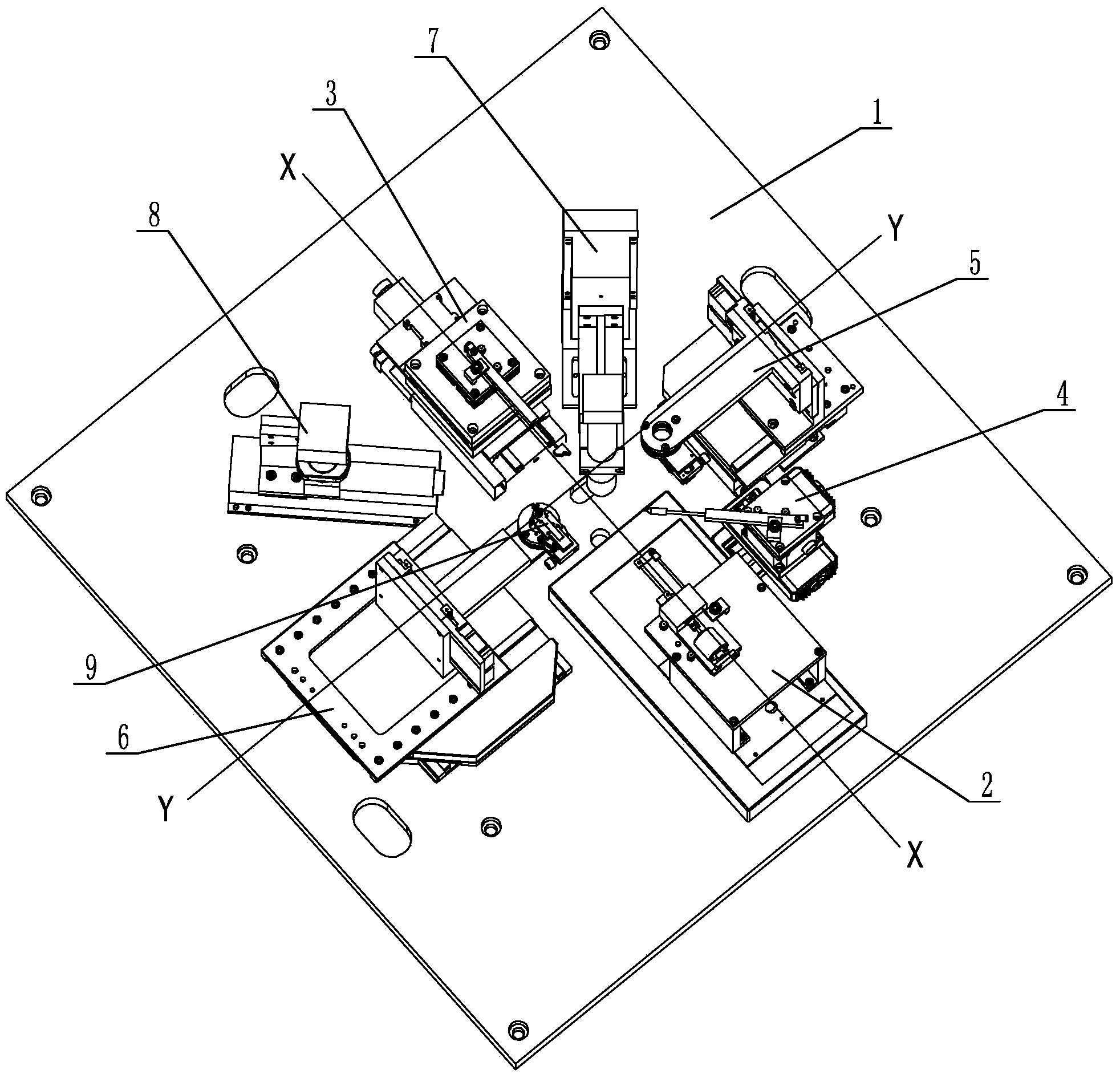

[0026] Embodiment 1: Combining figure 1 , Figure 16 and Figure 17 This embodiment is described. The automatic precision assembly platform for the key parts of fusion targets in this embodiment includes a substrate 1, a diagnostic ring preliminary positioning and clamping device 2, a diagnostic ring precise positioning and clamping device 3, a target pellet clamping and positioning device 4, and an upper set clamp. Holding and positioning device 5, lower kit clamping and positioning device 6, vertical microscope image feedback device 7 and horizontal microscope image feedback device 8, diagnostic ring preliminary positioning and clamping device 2, target pellet clamping and positioning device 4, upper kit clamping and positioning The device 5, the vertical microscope image feedback device 7, the diagnostic ring fine positioning and clamping device 3, the horizontal microscope image feedback device 8 and the lower set clamping and positioning device 6 are arranged on the uppe...

specific Embodiment approach 2

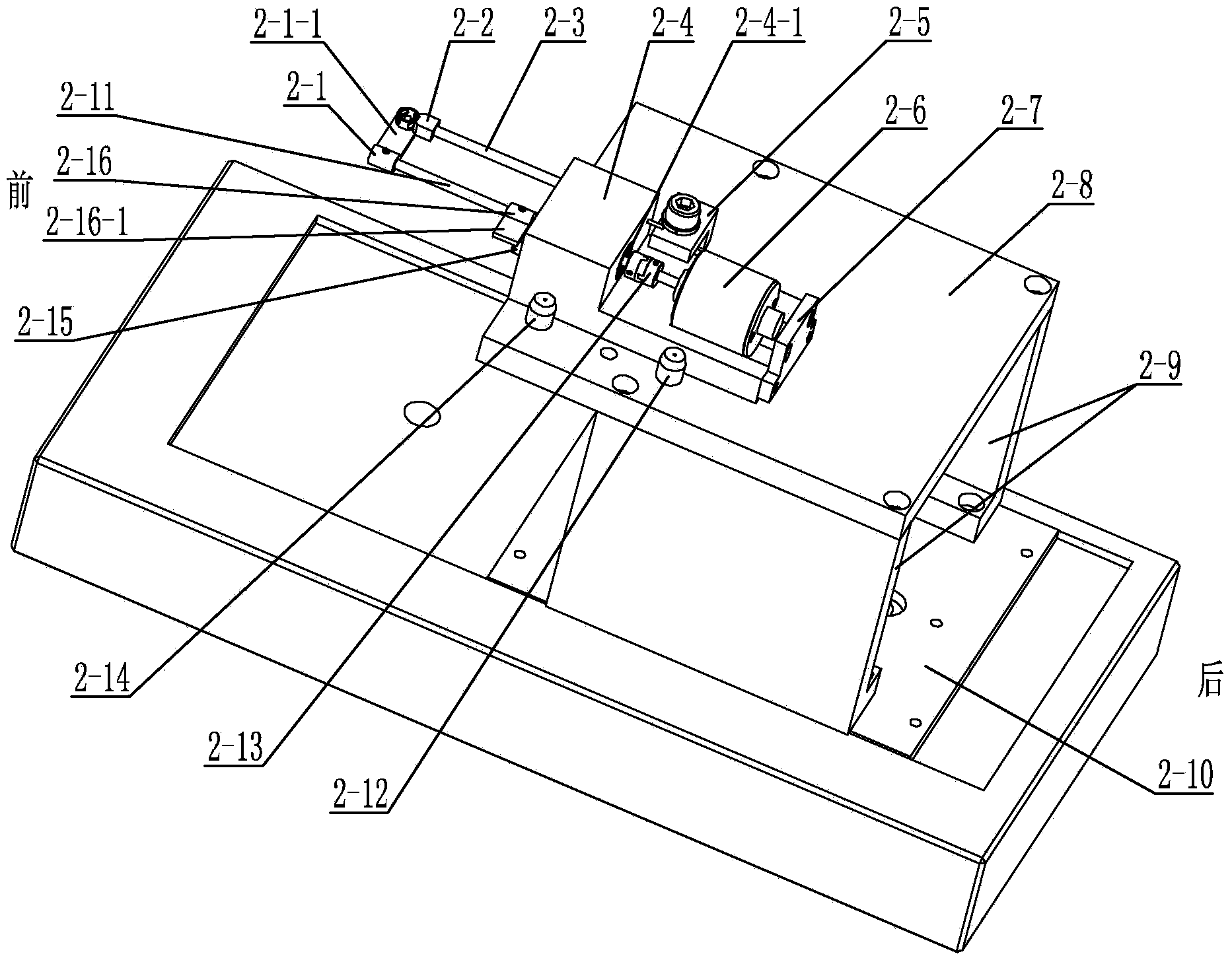

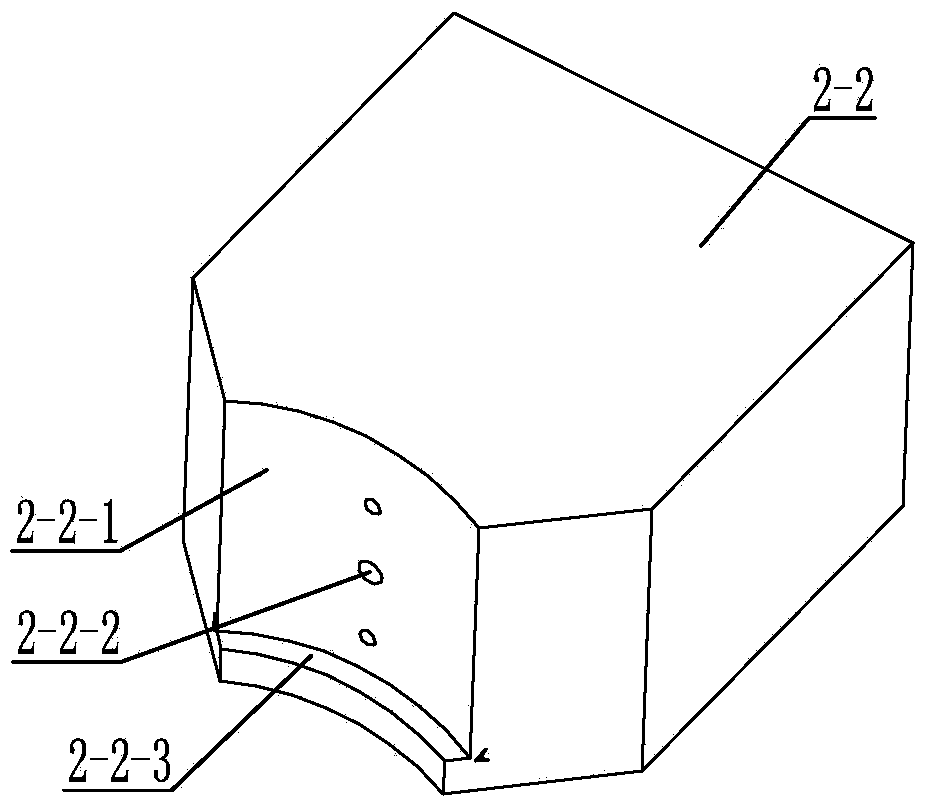

[0027] Specific implementation mode 2: Combining figure 2 and image 3Describing this embodiment, the diagnostic ring preliminary positioning and clamping device 2 of this embodiment includes a target pellet support 2-1, a preliminary positioning and clamping tip 2-2, an preliminary positioning pipette 2-3, an preliminary positioning block 2-4, Initial positioning L-shaped pressure block 2-5, rotating electromagnet 2-6, baffle plate 2-7, horizontal end plate 2-8, two L-shaped plates 2-9, initial positioning linear motor 2-10, rotating rod 2 -11, the first locating pin 2-12, the adapter 2-13, the second locating pin 2-14, the third locating pin 2-15 and the rotating positioning piece 2-16, the two L-shaped plates 2-9 are along a straight line The longitudinal center line of the motor 2-10 is symmetrically arranged on both sides of the upper end face of the initially positioned linear motor 2-10, and the inner corners of the two L-shaped plates 2-9 are arranged oppositely, and...

specific Embodiment approach 3

[0029] Specific implementation three: combination Figure 4 and Figure 5 Describing this embodiment, the diagnostic ring precise positioning and clamping device 3 of this embodiment includes a precise positioning suction head 3-1, a fourth positioning pin 3-2, a precise positioning suction tube 3-3, a precise positioning positioning rod 3-4, a precise positioning Positioning L-shaped pressure block 3-5, fifth positioning pin 3-6, fine positioning elbow 3-7, sixth positioning pin 3-8, seventh positioning pin 3-9, fine positioning connecting plate 3-10, fine adjustment Table 3-11, upper connecting plate 3-12, precise positioning linear motor 3-13, lower connecting plate 3-14 and precise positioning stepping motor 3-15, upper connecting plate 3-12, precise positioning linear motor 3-13 and the lower connecting plate 3-14 are sequentially arranged on the upper end surface of the fine positioning stepper motor 3-15 from top to bottom. 12, the fifth positioning pin 3-6 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com