Mill scale collecting system of bar straightener

An iron oxide scale and collection system technology, applied in the field of straightening machines, can solve the problems of increasing the labor intensity of the straightening workers, being difficult to clean up, and not having enough cleaning space at the straightening rollers, so as to reduce equipment maintenance and operation. Convenience and reliability, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

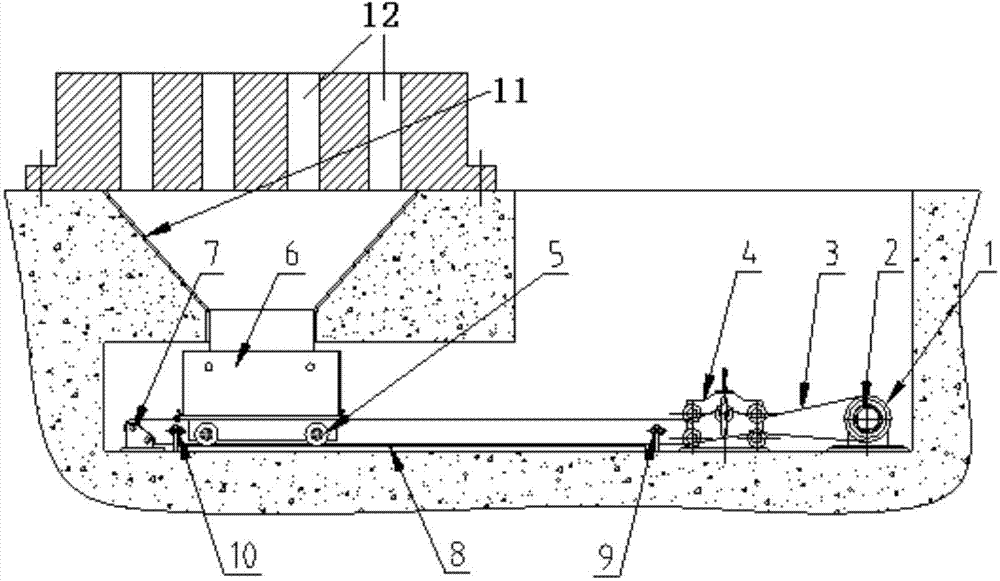

[0012] refer to figure 1 , figure 2 , a scale collection system for a bar straightening machine, including a geared motor 1, a reel 2, a steel wire rope 3, a tensioning mechanism 4, a moving trolley 5, a waste box 6, a fixed pulley block 7, a rail 8, and a front limit detection 9 , rear limit detection 10, funnel-shaped collection device 11 and lower beam 12;

[0013] The reduction motor 1 and the reel 2 are connected through a shaft coupling, and the reel 2 rotates with the reduction motor 1 . The two ends of the steel wire rope 3 are respectively connected to the two ends of the mobile trolley 5 and are wound on the reel 2 through the fixed pulley block 7 and the tension mechanism 4. The mobile trolley 5 is arranged on the rail 8, and the waste box 6 is stuck on the mobile trolley 5. Mobile trolley 5 walks on steel rail 8. Front limit detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com