Four-in-one breeding shed

A technology for breeding sheds and breeding rooms, applied in the field of four-position integrated breeding sheds, can solve the problems of poor connection and no integrated structure, and achieve the effects of compact overall structure, increased thermal insulation effect, and convenient addition and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

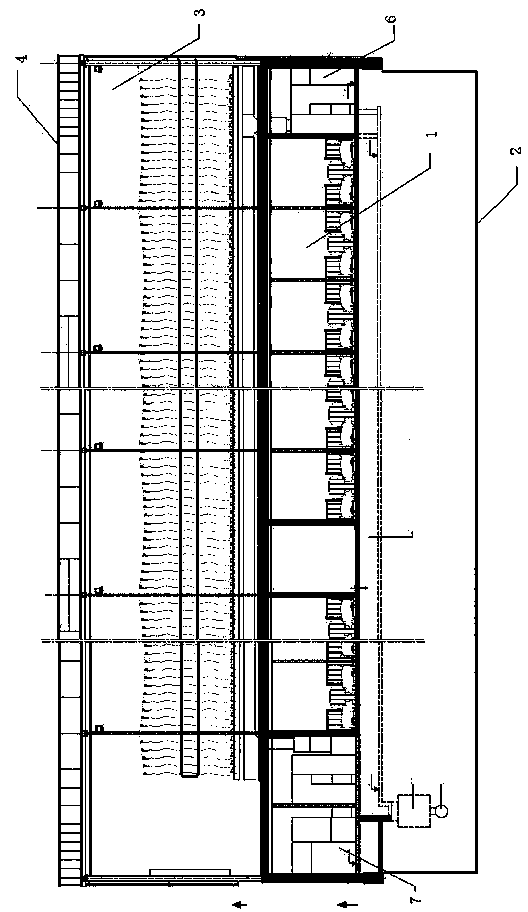

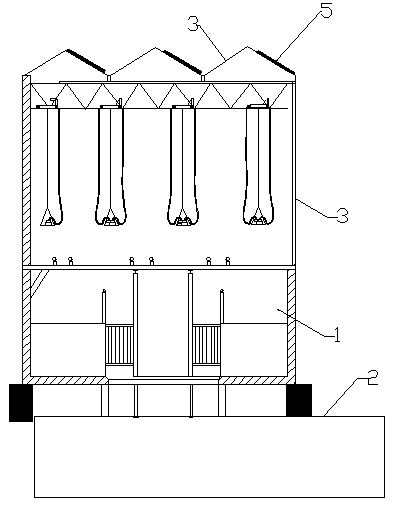

[0023] Specific implementation methods: such as figure 1 , 2 As shown, a four-position integrated breeding shed includes a greenhouse 3, the upper space in the greenhouse 3 is a plant planting greenhouse, and the lower space is provided with a breeding room 1, and the breeding room 1 and the planting greenhouse above the greenhouse pass through a partition separated; the biogas digester 2 is arranged below the cultivation room 1, and the sewage channel of the cultivation chamber 1 is connected to the feed port of the biogas digester 2. The greenhouse 3 includes three supporting thermal insulation walls and one light-transmitting wall. The thermal insulation wall of the greenhouse 3 adopts hot-dip galvanized steel sheets and steel pipes to assemble the skeleton, uses PC boards as walls, and is fixed by bolts or riveting. The south facade of Greenhouse 3 is assembled with single-layer float glass. The top of the greenhouse 3 is provided with a foldable top cover 4 of a three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com