Method for processing super-hydrophobic surface, and evaporator having super-hydrophobic surface

一种疏水性、蒸发器的技术,应用在加工极疏水性表面领域,能够解决难适用、长时间、表面强度弱等问题,达到容易形成、缩短时间、高耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement. However, the present invention is not limited to the embodiments described here, and the present invention can be realized in various forms.

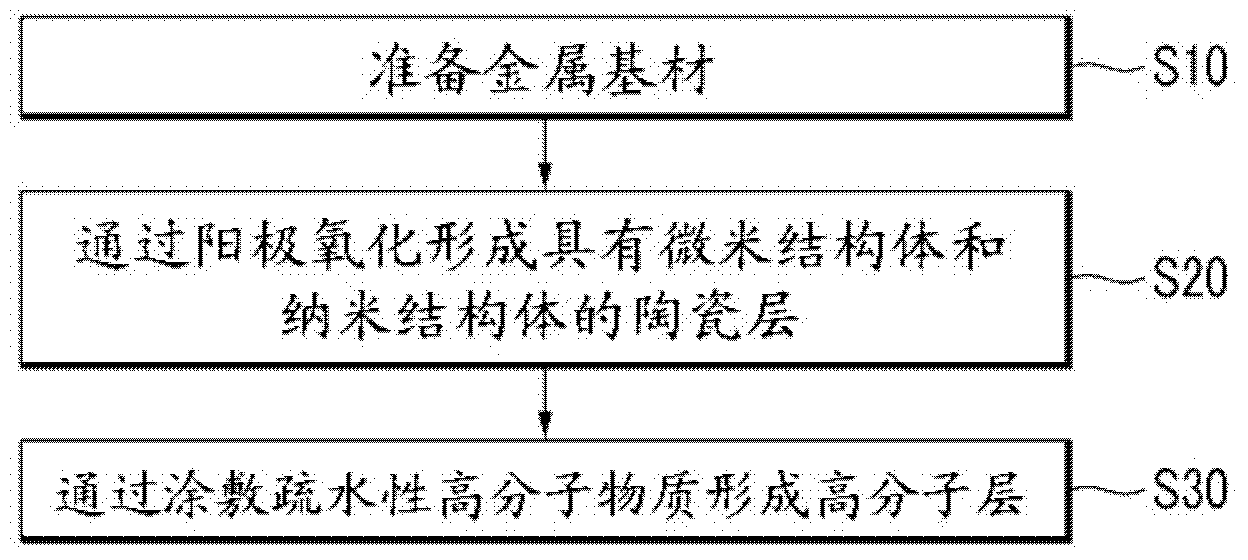

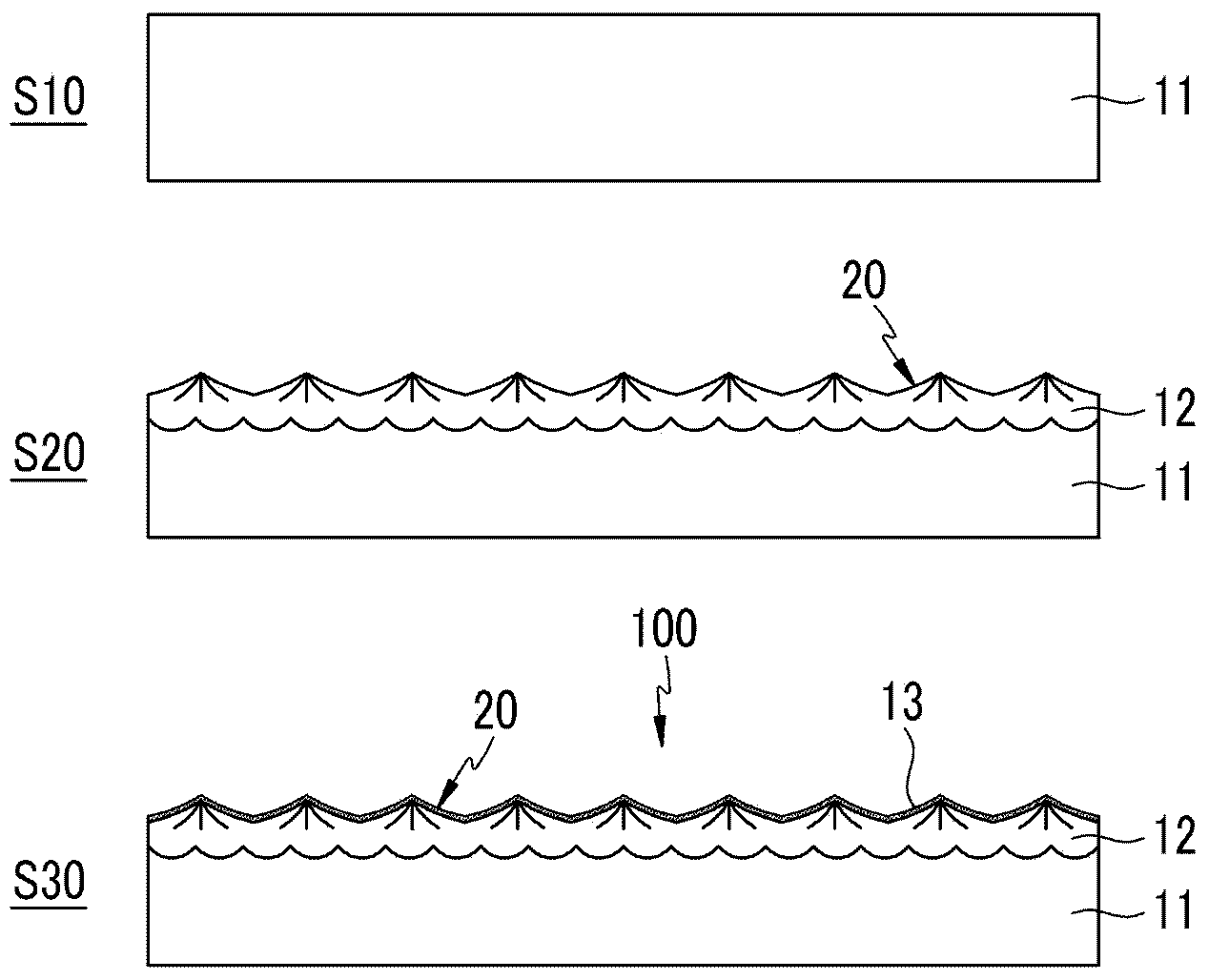

[0034] figure 1 It is a process flow diagram representing a method for processing an extremely hydrophobic surface according to an embodiment of the present invention, figure 2 to show schematically in figure 1 A diagram of the cross-sectional state under each step illustrated in .

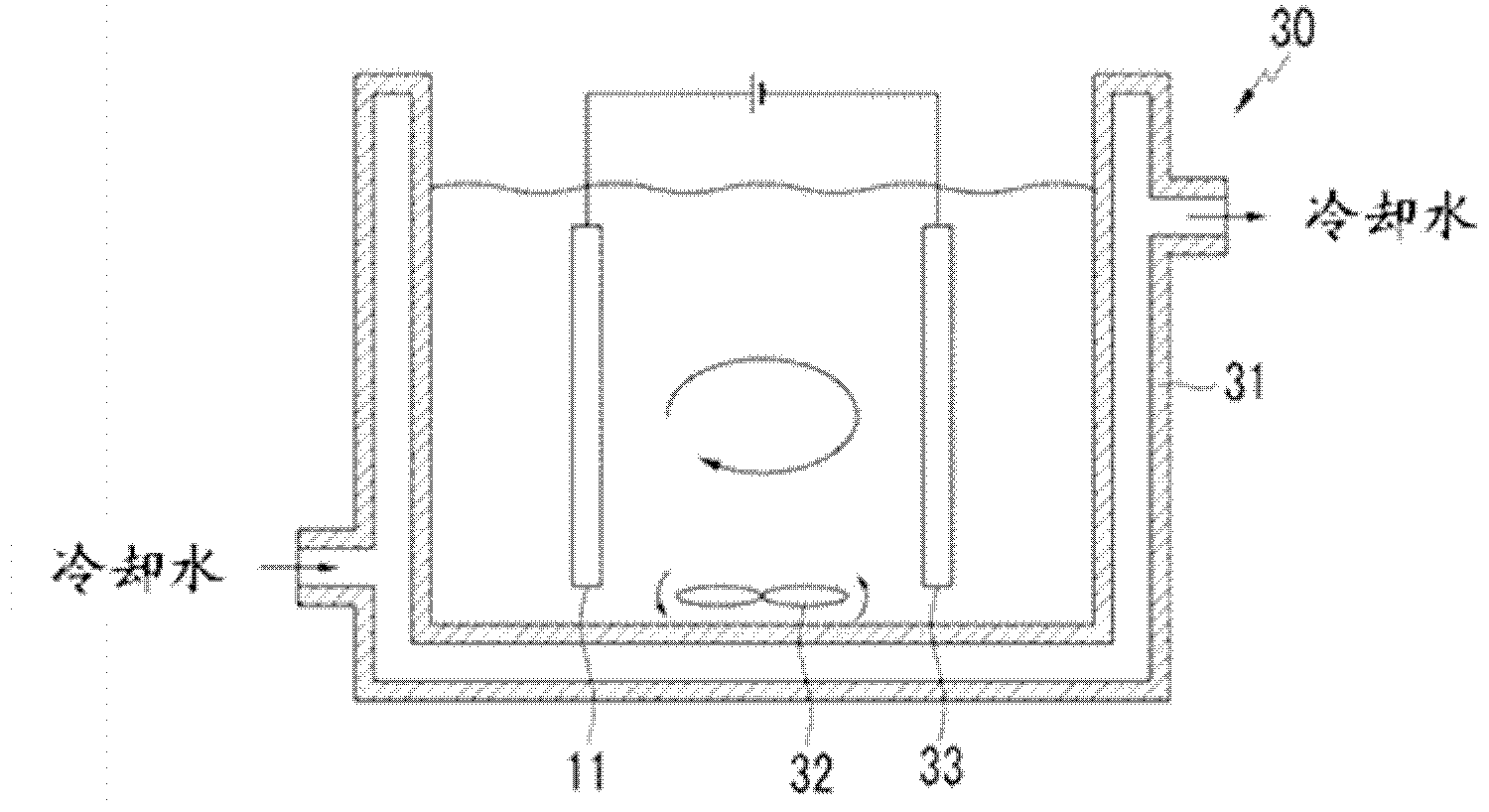

[0035] refer to figure 1 and figure 2 , the method for processing the extremely hydrophobic surface 100 of the present embodiment includes the first step S10 of preparing the metal substrate 11; anodizing the metal substrate 11 to form microstructures and nanometer structures on the surface of the metal substrate 11. The second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com