Pinch roll equipment

A pinch roll and equipment technology, applied in metal processing equipment, rolling force/roll gap control, metal rolling, etc., can solve the problems of low service life cycle, high operation and maintenance costs of servo valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

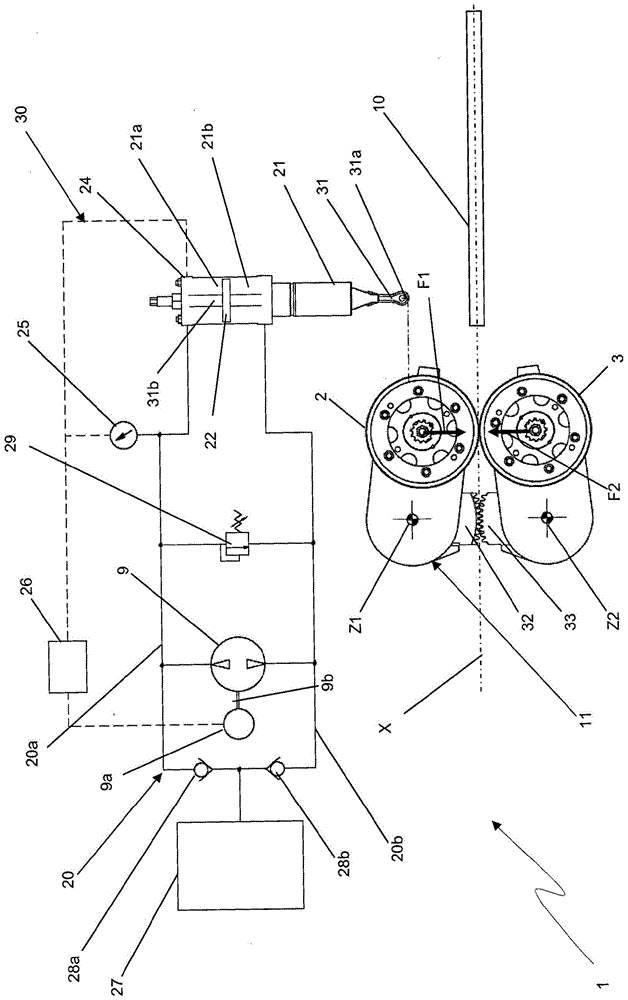

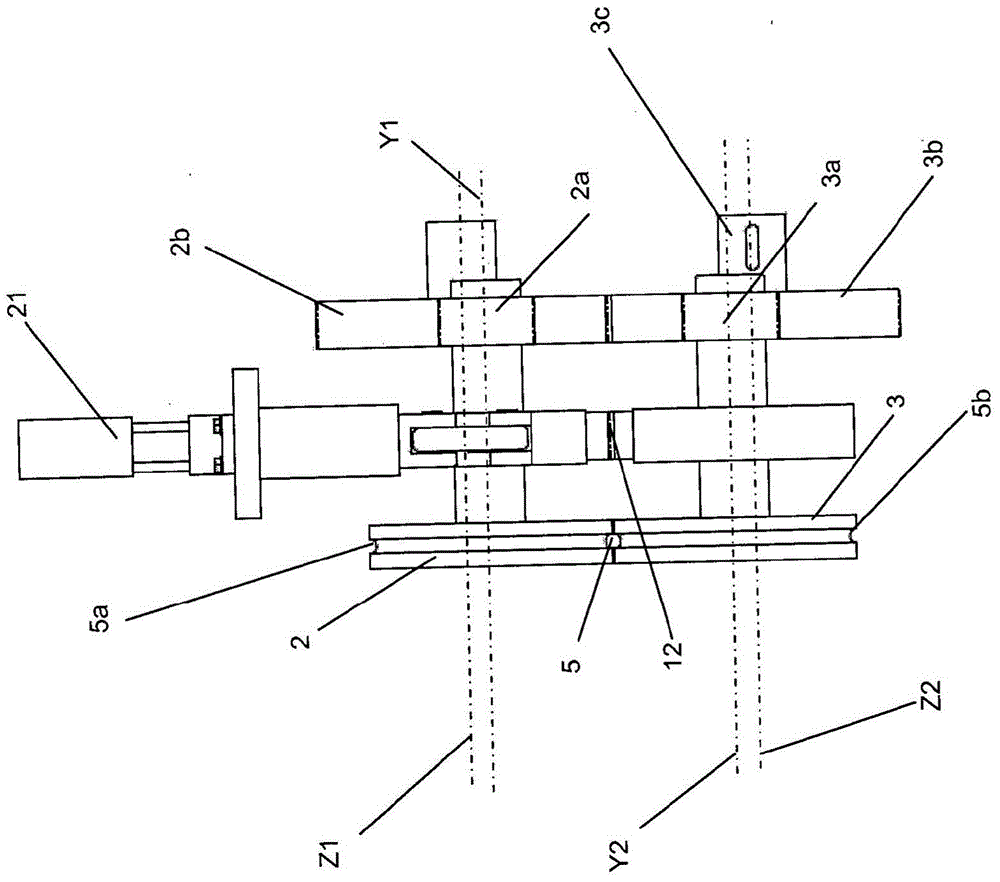

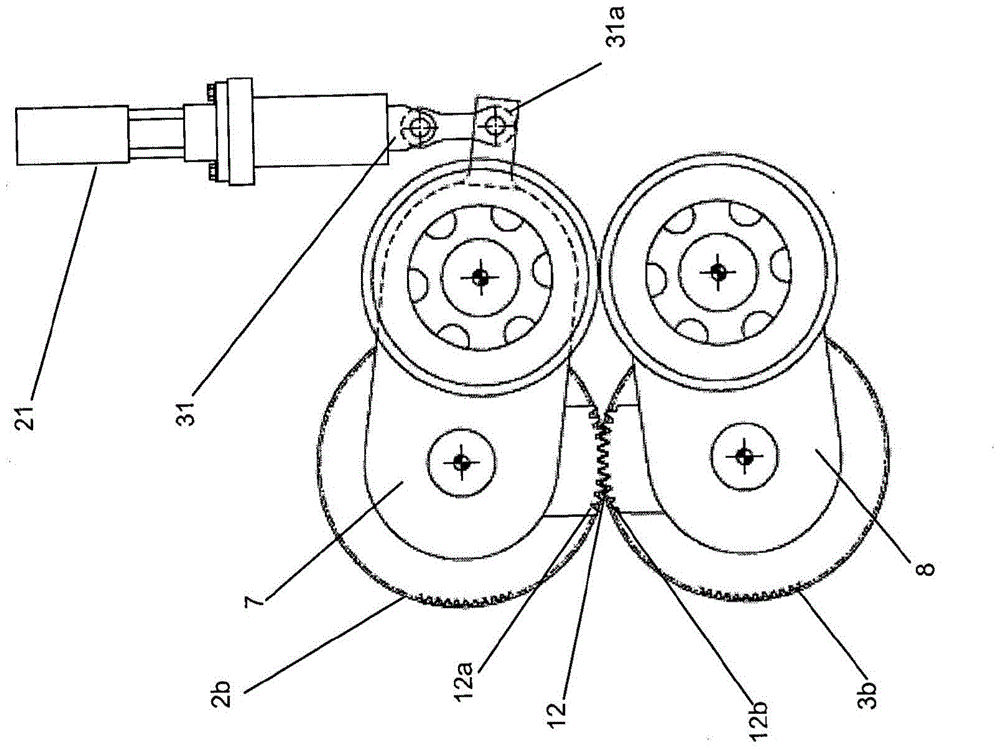

[0044] refer to Figure 1-3 , generally indicated by reference numeral 1 is a pinch roll arrangement for rolled metallurgical products of circular cross-section.

[0045] In general, pinch roll apparatus provided in accordance with the present invention may be suitably configured to grip any rolled metallurgical product, such as a flat cross-section rolled product.

[0046]The apparatus 1 comprises a first pinch roll 2 and a second pinch roll 3 identical to the first roll 3 between which a generally circular passage gap for a rod wire 10 is defined 5. The gap 5 defines a passage axis X coaxial with the gap 5 , with which the rod wire 10 is operatively aligned when passing through the passage gap 5 .

[0047] The first roller 2 and the second roller 3 can rotate around the first rotation axis Y1 and the second rotation axis Y2, respectively, to pull the rod wire 10 through the channel gap 5 by friction. The axes of rotation Y1 , Y2 are parallel to each other and at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com