vacuum circuit breaker

A technology of vacuum circuit breaker and vacuum interrupter, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of waste of capital cost and delay of working hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

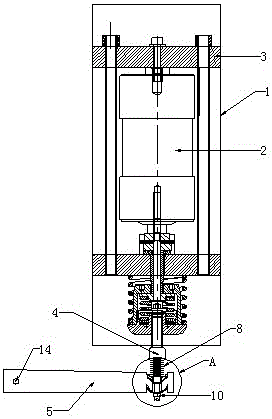

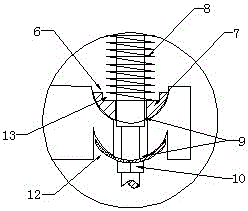

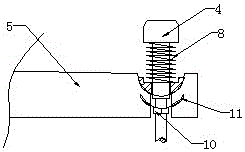

[0016] As shown in the figure, the vacuum circuit breaker of the present invention includes a housing 1 and a vacuum interrupter 2 arranged in the housing. The upper end of the vacuum interrupter 2 has a conductive plate 3 for conductive connection with the static contact. The moving contact at the lower end of the vacuum interrupter is connected to the push rod 4 located outside the housing through the moving contact part. The lower part of the push rod 4 has a drive plate 5 arranged perpendicular to the push rod, and one end of the drive plate 5 is installed on a fulcrum. And make the drive plate 5 swing around the fulcrum, the drive plate 5 upper end is provided with a hemispherical upper groove 6, the upper groove 6 is provided with a wear-resistant block 7 that cooperates with the upper groove 6, and the wear-resistant block 7 center is provided with For the central hole that the push rod passes through, a compression spring 8 is pressed between the drive plate 5 and the s...

Embodiment 2

[0019] As shown in the figure, the difference between this embodiment and Embodiment 1 is that the arc-shaped groove is a lower groove 12 of a hemispherical structure arranged on the rear end surface of the drive plate 5, and the wear-resistant block 7 and the limit nut 10 are installed in the upper concave groove respectively. In the groove 6 and the lower groove 12, this integral structure is easy to install and has better reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com