Method for detecting steady state and judging operation condition of water treatment process in thermal power plant

A technology for thermal power plants and operating conditions, which is applied in electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as misjudgment, sensor data fluctuation, and difficulty in obtaining good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

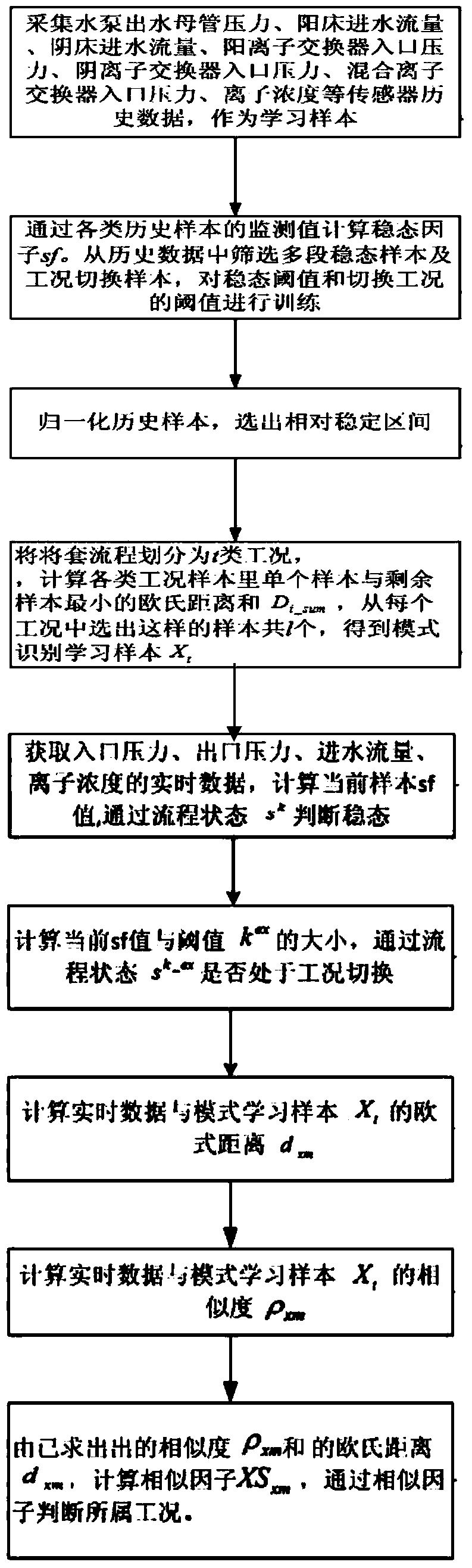

[0062] refer to figure 1 , a method for steady-state detection and operating condition discrimination of a thermal power plant water treatment process related to the present embodiment is characterized in that it includes the following steps:

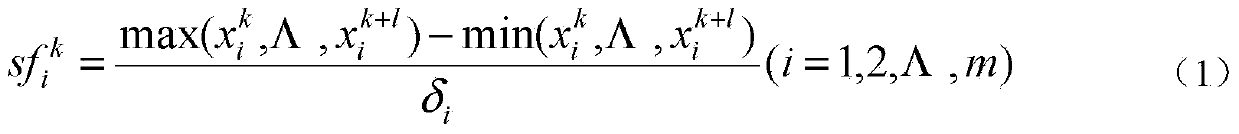

[0063] 1) Determine the steady state threshold and working condition switching threshold of each sensor in the water treatment system of the thermal power plant

[0064] Determine the steady state valve of each sensor by collecting the water pump outlet jellyfish pipe pressure, positive bed water flow, negative bed water flow, cation exchanger inlet pressure, anion exchanger inlet pressure, mixed ion exchanger inlet pressure and ion concentration sensor data value and working condition switching threshold;

[0065] 2) Determine the working condition stage of the water treatment system

[0066] 2-1) Detect the dynamic data of each sensor in the water treatment system, and compare the detected data with the steady-state threshold value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com