A kind of tungsten-molybdenum-iron alloy and preparation method thereof

A ferroalloy, tungsten-molybdenum technology, which is applied in the field of tungsten-molybdenum-iron alloy and its preparation, can solve the problems of large difference in the proportion of tungsten-molybdenum elements, difficulty in melting, and inconformity with the ratio relationship of tungsten-molybdenum addition, so as to achieve uniform distribution, increase strength, and avoid escape. out loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

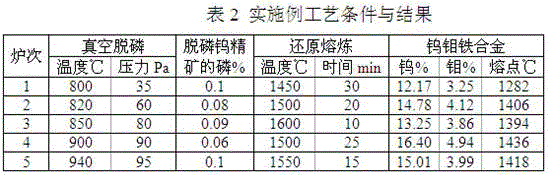

[0047] Raw material: low-grade tungsten concentrate, produced in Luanchuan, Henan, the chemical composition is shown in Table 1.

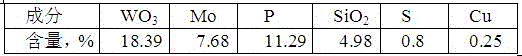

[0048] Implementation process: raw materials are dehydrated at 80~200°C for 1.5 hours, crushed to a particle size of 100~200 mesh; according to the weight ratio of tungsten concentrate, silica, and coal powder is 100:28:16, add silica to tungsten concentrate and coal powder and mix evenly; the mixture is placed in a vacuum reduction furnace, heated at 35~95Pa, 800~940°C for 30 minutes, dephosphorized in a vacuum, and the phosphorus-containing furnace gas is introduced into a sealed water circulation cooling box to deposit phosphorus vapor and collect Solid phosphorus, and get dephosphorized tungsten concentrate, P≤0.1% in dephosphorized tungsten concentrate; dephosphorized tungsten concentrate with ferrosilicon, aluminum particles, silica, iron filings, lime in a weight ratio of 100:0.8:5: 3:98:0.8 ratio, mixed evenly; the mixture is placed in a sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com