Preparation method of elsholtziae extract

A kind of extract of fenugreek and the technology of fenugreek, applied in the direction of solid solvent extraction, essential oil/fragrance, chemical/physical/physicochemical process of energy application, etc., to achieve the effect of increasing solubility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

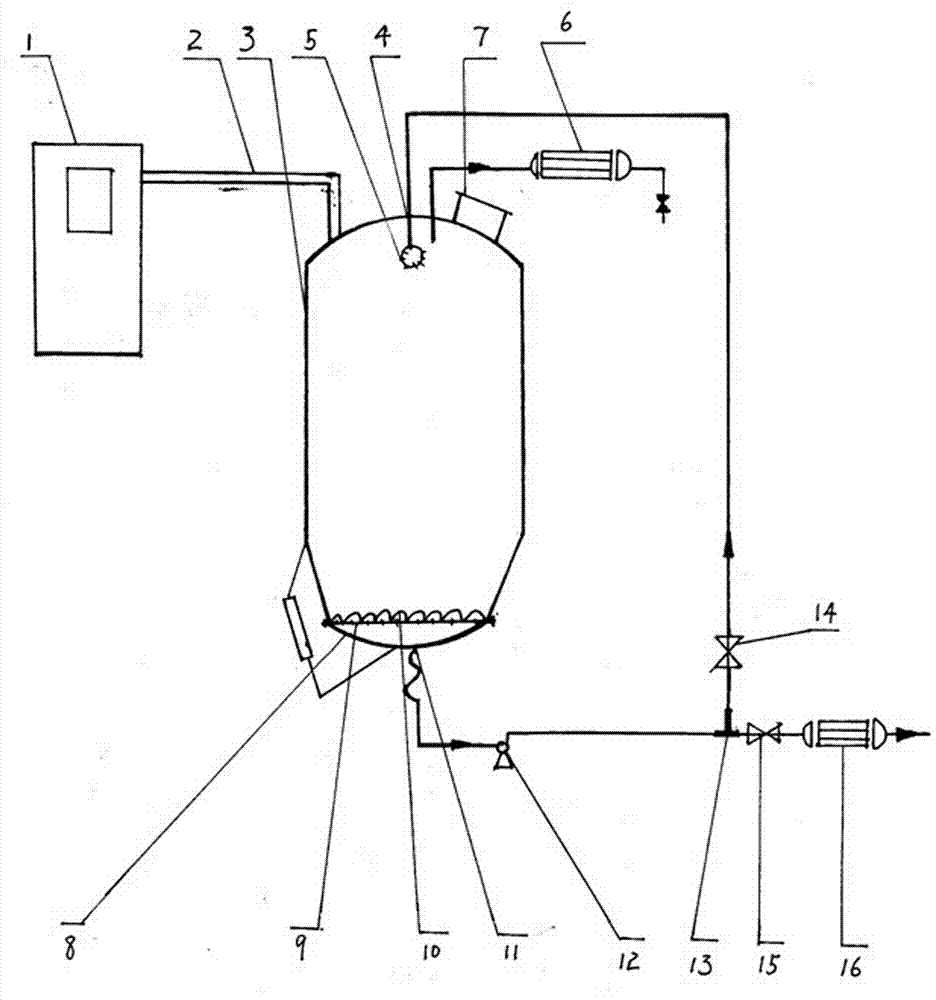

Method used

Image

Examples

Embodiment 1

[0026] (1) Microwave extraction: Weigh 100kg of dried fenugreek and cut them into small pieces of 1-2mm, place them in a microwave extraction tank, add 800kg of pure water, turn on microwave heating, and when the temperature rises to 60°C, turn on the circulation bypass, Realize the circulation flow of the extract of the fennel extract in the tank, and keep the full contact of the fennel and the solution. Set the extraction temperature to 95°C, and then microwave extraction for 20 minutes when it reaches 95°C; stop the heating, stop the operation of the circulation bypass system, and cool the extraction liquid from the discharge port to 40°C through the heat exchanger and pour it into the feed liquid storage tank , to obtain the water extract A; the chrysanthemum residue is still in the microwave extraction tank, and then add 400kg of pure water to the microwave extraction tank for the second extraction, turn on the microwave heating, and when the temperature rises to 60 ° C, t...

Embodiment 2

[0030](1) Microwave extraction: Weigh 120kg of dried fenugreek and cut it into 1-2mm pieces, put it in an extraction tank, add 720kg of pure water, turn on microwave heating, and turn on the circulation bypass when the temperature rises to 60°C. Set the extraction temperature to 60°C, microwave extraction for 60 minutes; stop heating, stop the operation of the bypass system, cool the extraction liquid from the discharge port to 35°C through a heat exchanger, and put it into the feed liquid storage tank to obtain the water extraction liquid A; Add 900kg of pure water to the microwave extraction tank for the second extraction, turn on the microwave heating, and when the temperature rises to 60°C, turn on the bypass, and set the extraction temperature to 80°C. When it rises to 80°C, microwave extraction for 5 minutes; stop heating, stop the operation of the bypass system, cool the extract from the outlet to 38°C through a heat exchanger, and put it into the feed liquid storage tan...

Embodiment 3

[0035] (1) Microwave extraction: Weigh 80kg of dried fenugreek and cut them into small pieces of 1-2mm, put them in the extraction tank, add 640kg of pure water, turn on microwave heating, and turn on the circulation bypass when the temperature rises to 60°C. Set the extraction temperature to 70°C, microwave extraction for 5 minutes; stop heating, stop the operation of the bypass system, and pour the extract into the feed liquid storage tank after being cooled by the heat exchanger at the discharge port to obtain the water extract A; then add Put 400kg of pure water into the microwave extraction tank for the second extraction, turn on the microwave heating, when the temperature rises to 60°C, turn on the bypass, set the extraction temperature to 80°C, and then microwave extraction for 60 minutes when the temperature rises to 80°C; stop Heating, stopping the operation of the bypass system, cooling the extract from the outlet through the heat exchanger and pumping it into the fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com