Real-time monitoring and positioning system of cable crane

A real-time monitoring and positioning system technology, applied in cable cranes, cranes, load hanging components, etc., can solve the difficulty of finding the target loading position and the target unloading position, and it is difficult to obtain the space position of the cable crane in real time and accurately, construction efficiency and construction Safety hazards and other issues, to avoid irregular construction behavior, improve construction efficiency and construction intensity, and shorten the construction period of the project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

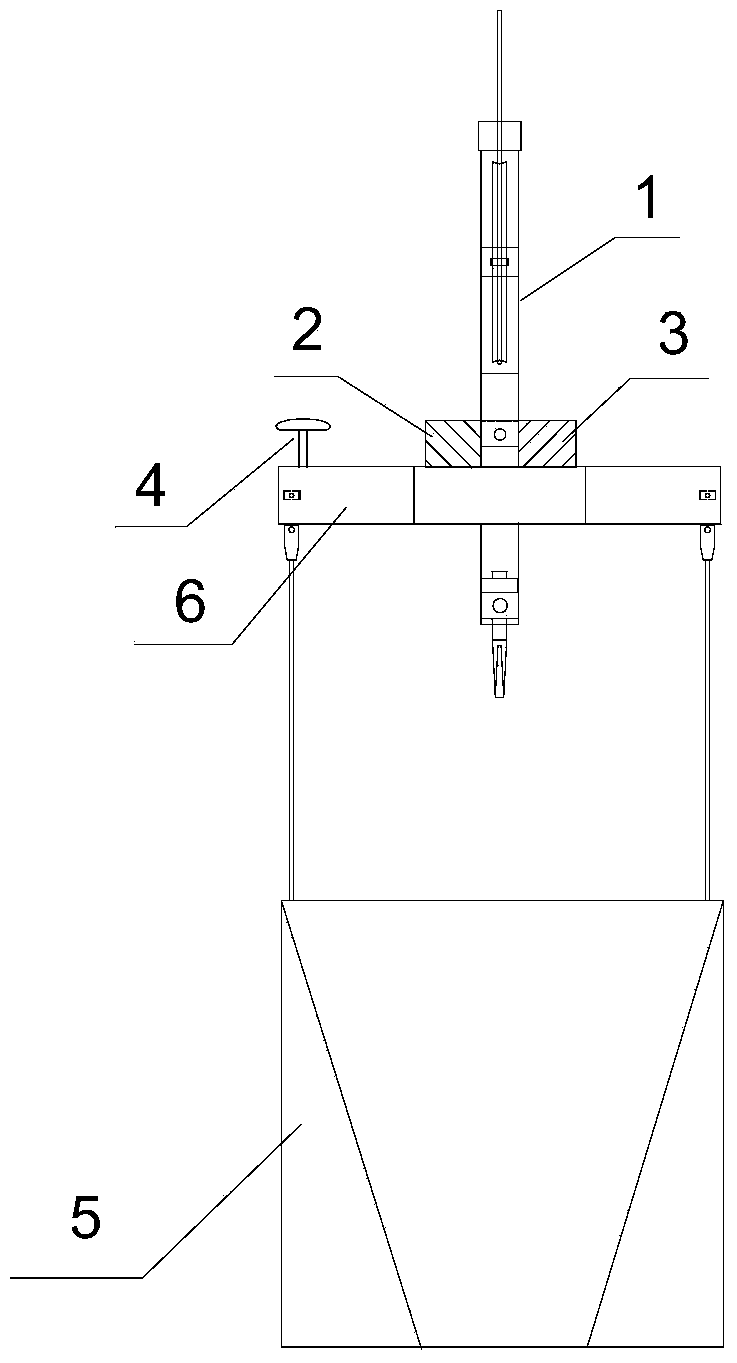

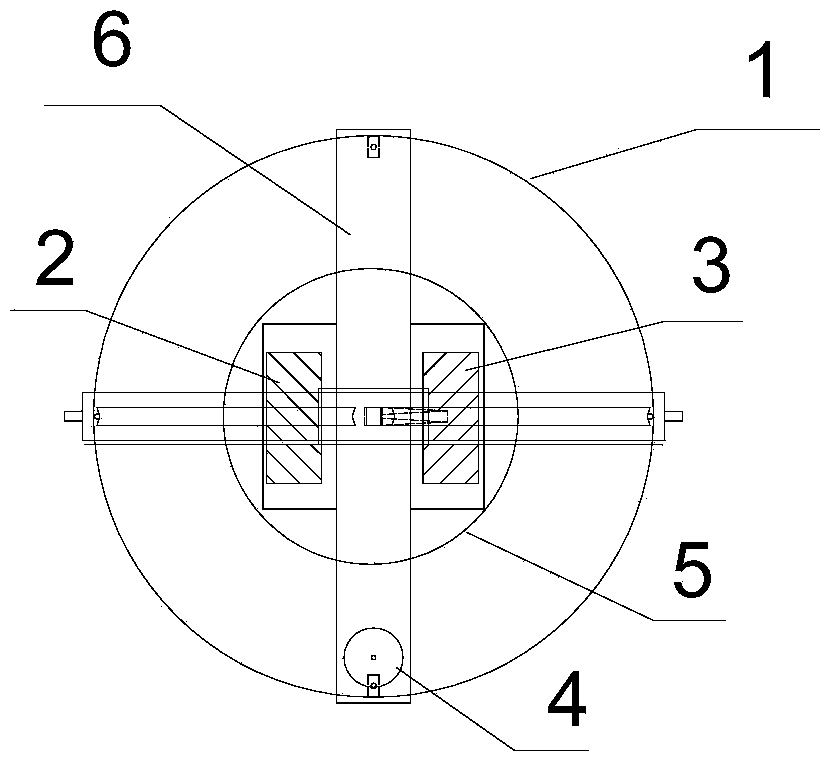

[0015] Such as figure 1 and figure 2 The shown cable machine real-time monitoring and positioning system of the present invention comprises a cable machine hook 1, and a material tank 5 is hoisted under the cable machine hook 1, and is connected with the cable machine hook 1 in a plane perpendicular to the cable machine hook 1 suspension line. A horizontal support 6 is provided on which a positioning host 2, a power supply module 3 and a positioning antenna 4 for receiving satellite positioning signals are fixed, and the power supply module 3 and the positioning antenna 4 are respectively connected to the positioning host 2 by wire. The positioning antenna 4 is arranged near the axial end point of the horizontal support 6 to enhance satellite signal reception, avoid signal interference, and ensure accurate positioning. The positioning host 2 is provided with a wireless module (not shown), and is wirelessly connected to a remote server (not shown) via WiFi. The power module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com