Tilting four-rotor-wing aircraft

A technology of tilting quadrotors and tilting rotors, which is applied in the field of aircraft to achieve the effects of improving maneuverability, increasing internal carrying space, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

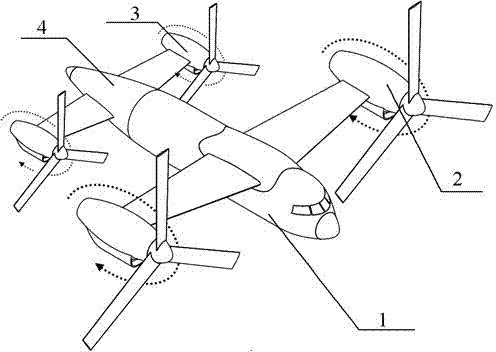

[0016] as the picture shows. A tiltable four-rotor aircraft, comprising a fuselage 1, a main tilt rotor 2, an auxiliary tilt rotor 3, a tail section 4, a main wing 5, and an auxiliary wing 6, the tail section 4 is installed at the tail of the fuselage 1, Two main wings 5 are installed on the two sides of the fuselage 1, and two auxiliary wings 6 are installed on the two sides of the tail section 4, and the end of the main wing 5 away from the fuselage 1 is equipped with a main tilting rotor 2, and the auxiliary wing 6 An auxiliary tilt rotor 3 is installed at the end away from the tail section 4 , the main tilt rotor 2 can rotate along the axial direction of the wing 5 , and the auxiliary tilt rotor 3 can rotate along the axial direction of the wing 6 . When the aircraft takes off, the rotors of the main tilting rotor 2 and the auxiliary tilting rotor 3 face upward, and when the rotors rotate, the aircraft obtains upward power. When the aircraft needs to fly forward, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com