Pearl holing machine

A punching machine and pearl technology, which is applied in metal processing and other directions, can solve the problems of automatic feeding and automatic drilling, and achieve the effect of improving punching efficiency, convenient operation and ensuring processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

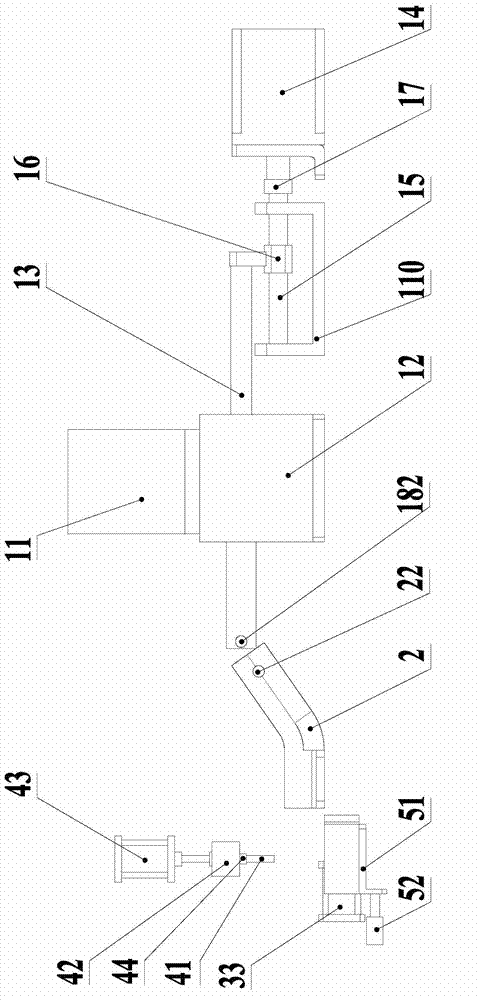

[0026] Such as figure 1 , 2 As shown, the pearl punching machine includes a base, a clamping mechanism and a punching mechanism fixed on the base; the base is provided with a feeding mechanism and a material guiding mechanism 2; the feeding mechanism includes a hopper 11, and the hopper 11 The connected feeding mold 12 and the pushing mechanism that pushes the pearls Z in the feeding mold 12 into the material guide mechanism 2 . A discharge port is provided below the hopper 11, and only a single pearl Z is allowed to be discharged from the discharge port in the width direction.

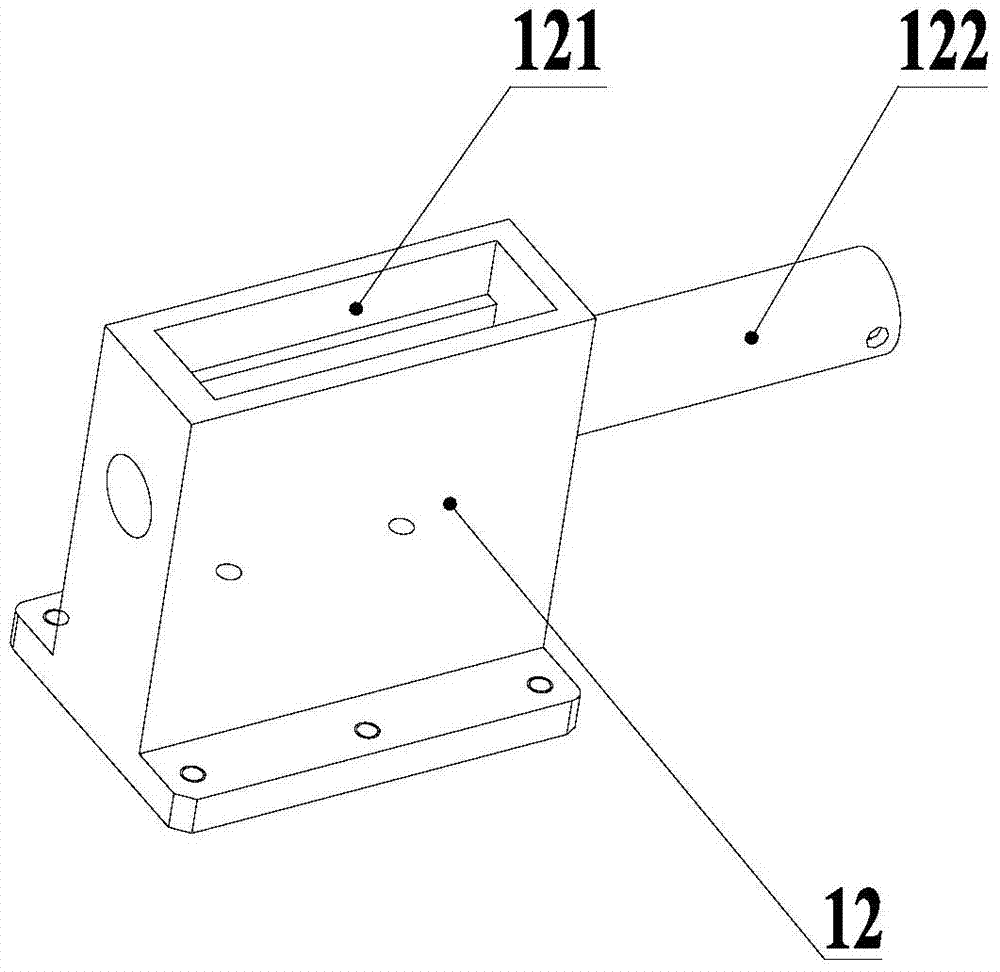

[0027] Such as image 3 As shown, the feeding mold 12 has a material chamber 121 communicated with the discharge port, and the material chamber 121 only allows a single pearl Z to enter in the width direction; the pushing mechanism includes a push rod 13 inserted into the material chamber 121, fixed The pushing power source 14 and the transmission mechanism on the base, the pushing power source 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com