Method and device for improving utilization rate of alkali liquor at alkaline cleaning section of vacuum potassium carbonate desulfurization technique

A technology of vacuum potassium carbonate and desulfurization process, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of large amount of waste liquid and low utilization rate of NaOH lye, and achieve the effect of saving consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

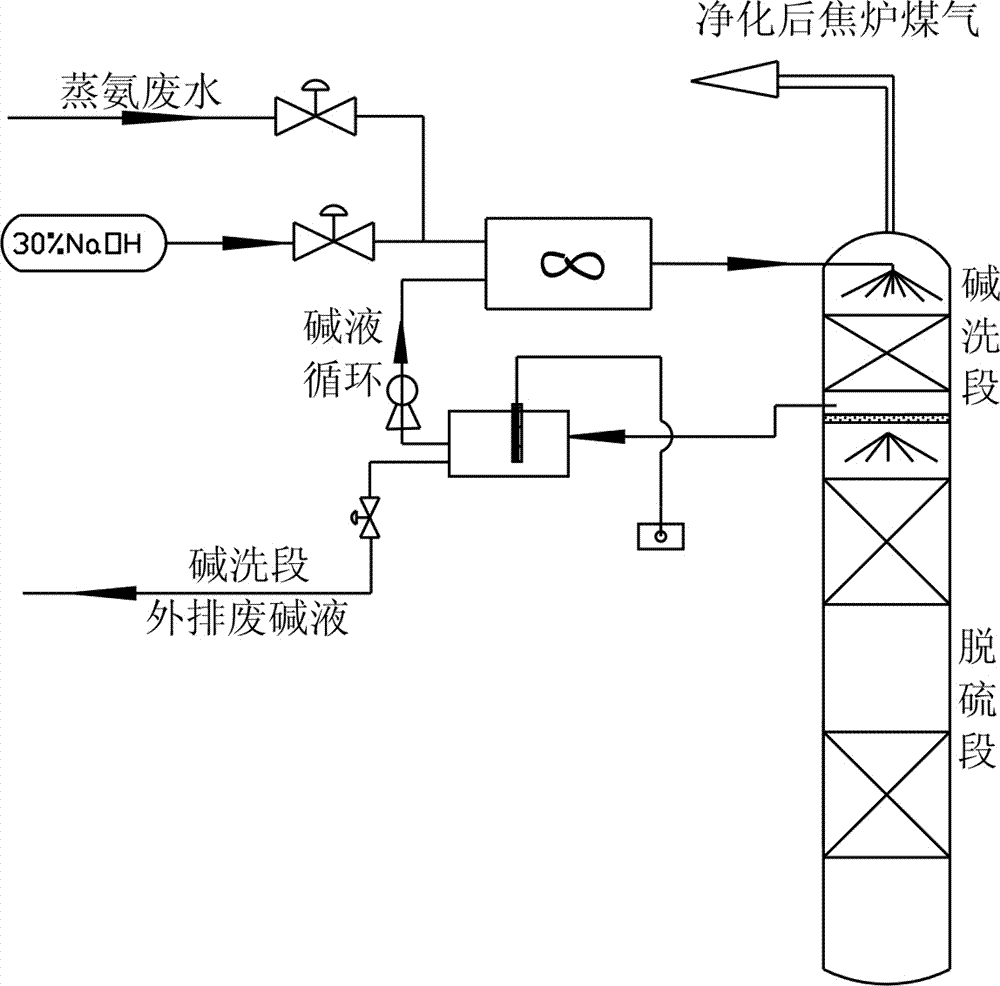

[0025] Such as figure 1 The device for improving the utilization rate of lye in the alkali washing section of the vacuum potassium carbonate desulfurization process includes a NaOH lye tank 1, a spent alkali tank 2 and a pH online monitoring system 3, and the NaOH lye tank is provided with lye Import 1-1, lye outlet 1-2 and waste caustic reflux port 1-3, the lye inlet of described NaOH lye tank is provided with import pipeline, and described import pipeline is divided into two branches, It is respectively used to pass into ammonia distillation waste water and NaOH solution. Flowmeters 4 are arranged on the two branch roads to adjust the flow of ammonia distillation waste water and NaOH solution accordingly. Agitator 5 is provided in the NaOH lye tank. The lye outlet of the NaOH lye tank is connected to the upper part of the sodium hydroxide alkali washing section of the desulfurization tower 6 through a pipeline, and the spent soda tank is provided with a spent soda inlet 2-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com