Production and processing process for frozen fresh mutton

A processing technology, mutton technology, applied in the field of chilled mutton production and processing technology, to achieve the effect of prolonging the preservation time, high amino acid content, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

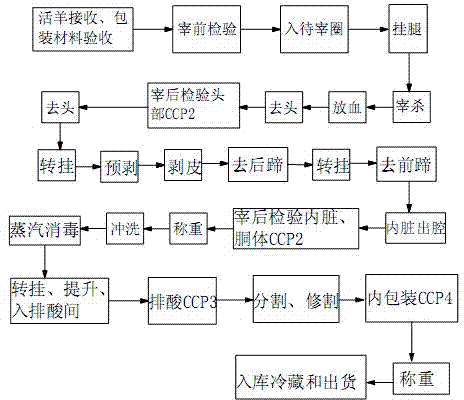

[0016] A chilled mutton production and processing process, the processing process includes the following steps: live sheep receiving, packaging material acceptance, pre-mortem inspection, put into the pen to be slaughtered, hanging legs, slaughter, bloodletting, head removal, post-mortem inspection head CCP2, Transfer, pre-peeling, skinning, heel removal, transfer, fore hoof removal, evisceration, post-mortem inspection of viscera, carcass CCP2, weighing, rinsing, steam sterilization, steam sterilization, transfer, lifting, deacidification Room, acid discharge CCP3, segmentation, trimming, inner packaging CCP4, weighing, refrigerated storage and shipment.

[0017] Combined with the specific requirements, specify the specific requirements of the relevant steps in detail.

[0018] In the above-mentioned ante-mortem inspection steps, the staff first check the "Animal Origin Quarantine Certificate" issued by the veterinarian of the animal inspection department, then the buyer visu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com