Vibration aging processing device of motor iron core

A technology of vibration aging and iron core, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of long time consumption, complicated process and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

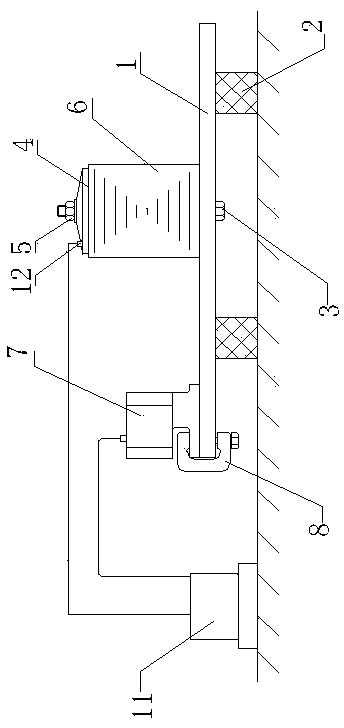

[0012] as attached figure 1 As shown, the vibration aging treatment device for the motor iron core includes a vibration platform 1, a rubber foot 2 is provided under the vibration platform, and an iron core pressing device is provided in the middle of the vibration platform, and the iron core pressing device includes an iron core The positioning rod 3, the iron core pressing plate 4 and the compression nut 5, when the iron core 6 sits on the vibration platform 1 through the iron core positioning rod 3, the iron core pressing plate 4 is pressed on the top of the iron core and passed the pressure on the top of the iron core positioning rod. Tight nut 5 is locked.

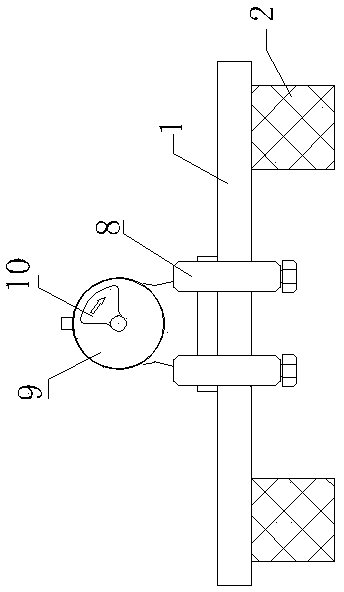

[0013] as attached figure 1 As shown, the device also includes a resonant vibrator 7, and the resonant vibrator 7 is clamped on one end of the vibrating platform 1 through a clamp 8.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com