Signal testing device of fixed frequency sensor

A technology of signal testing and fixed frequency, which is applied in the field of sensor detection, can solve the problems of not being able to know the sensor product, not giving the Hall sensor detection, etc., to achieve the effect of improving efficiency, visually seeing the detection results, and taking less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and examples.

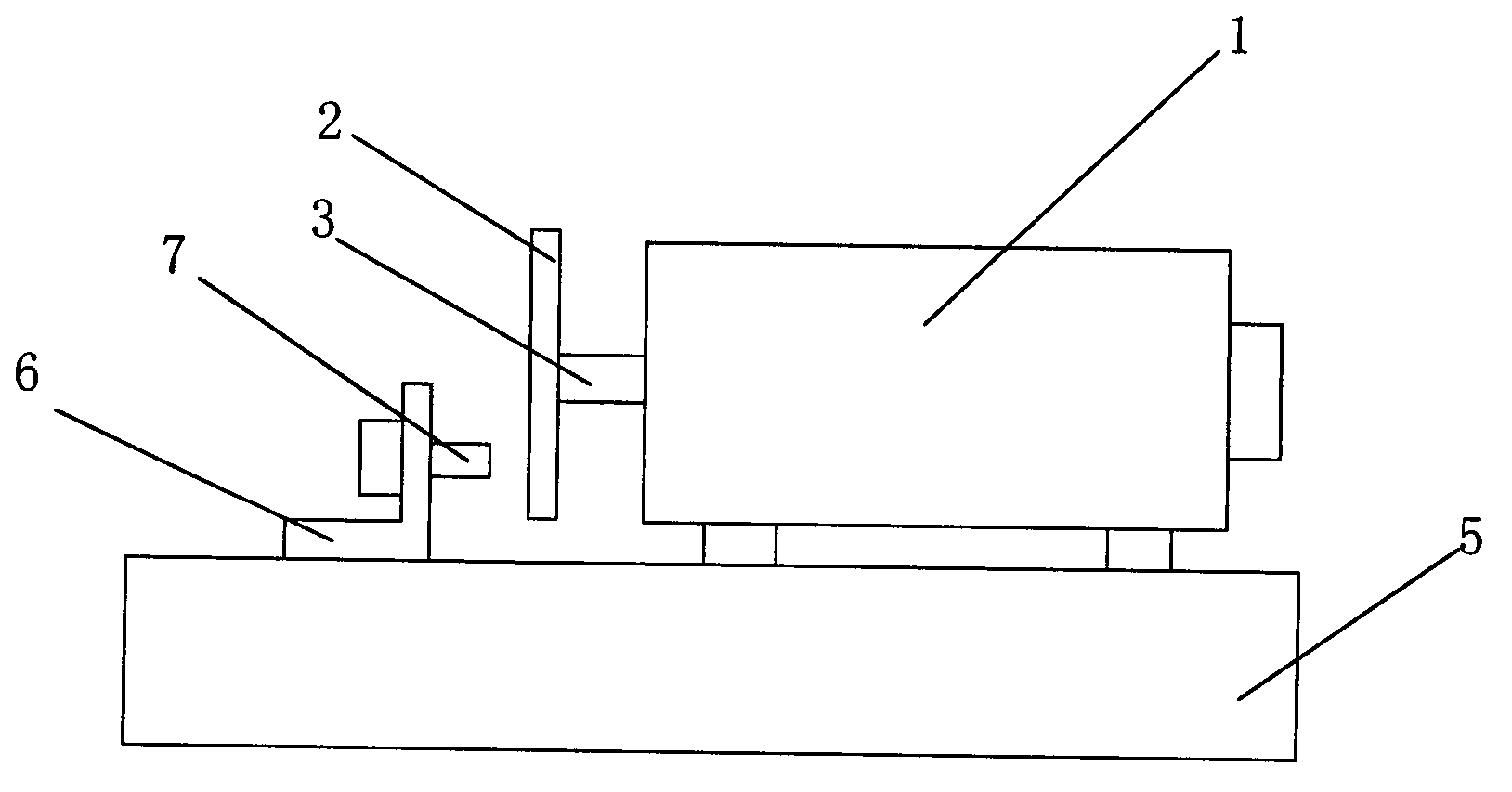

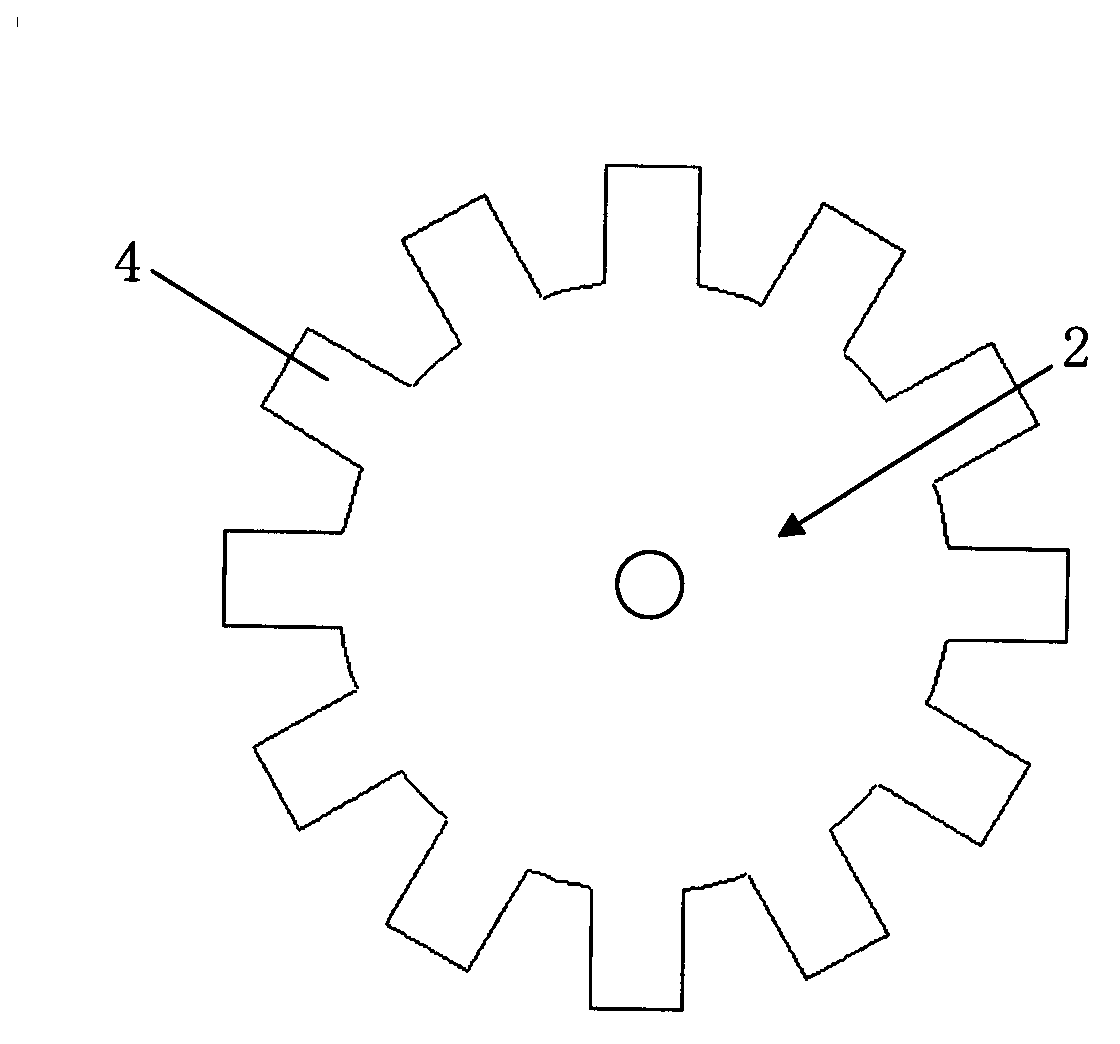

[0016] figure 1 It is a structural schematic diagram of the signal testing device of the fixed frequency sensor of the present invention; figure 2 It is a structural schematic diagram of the signal disc in the signal testing device of the fixed frequency sensor of the present invention.

[0017] Such as figure 1 , figure 2 As shown, the signal testing device of the fixed frequency sensor of the present invention includes: a motor 1 driven by a power source to drive the motor shaft 3 to rotate; Teeth 4, the center position of the signal plate is fixed with the motor shaft, driven by the motor and rotates coaxially with the motor shaft; the test platform 5, the motor and the sensor fixing frame 6 are fixed on the upper plane; the sensor fixing frame 6 is installed on the test platform, fixed Sensor, whose position corresponds to the signal plate on the motor; power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com