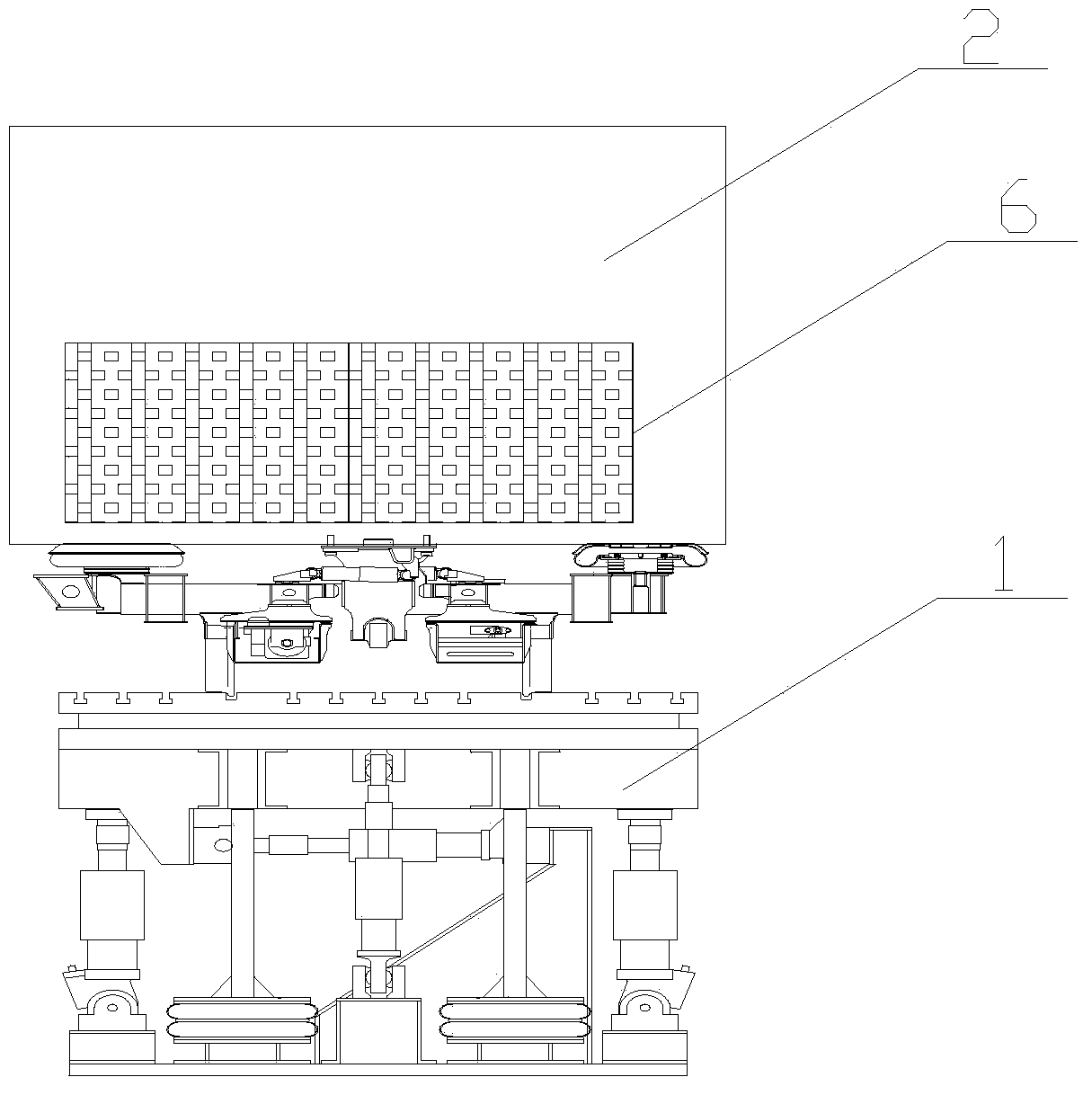

Rail vehicle operation performance testing device

A technology of running performance and testing device, applied in the direction of railway vehicle testing, etc., can solve the problem that the suspension system and stress conditions cannot be fully considered, and achieve the effects of saving test funds, accurate test results, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

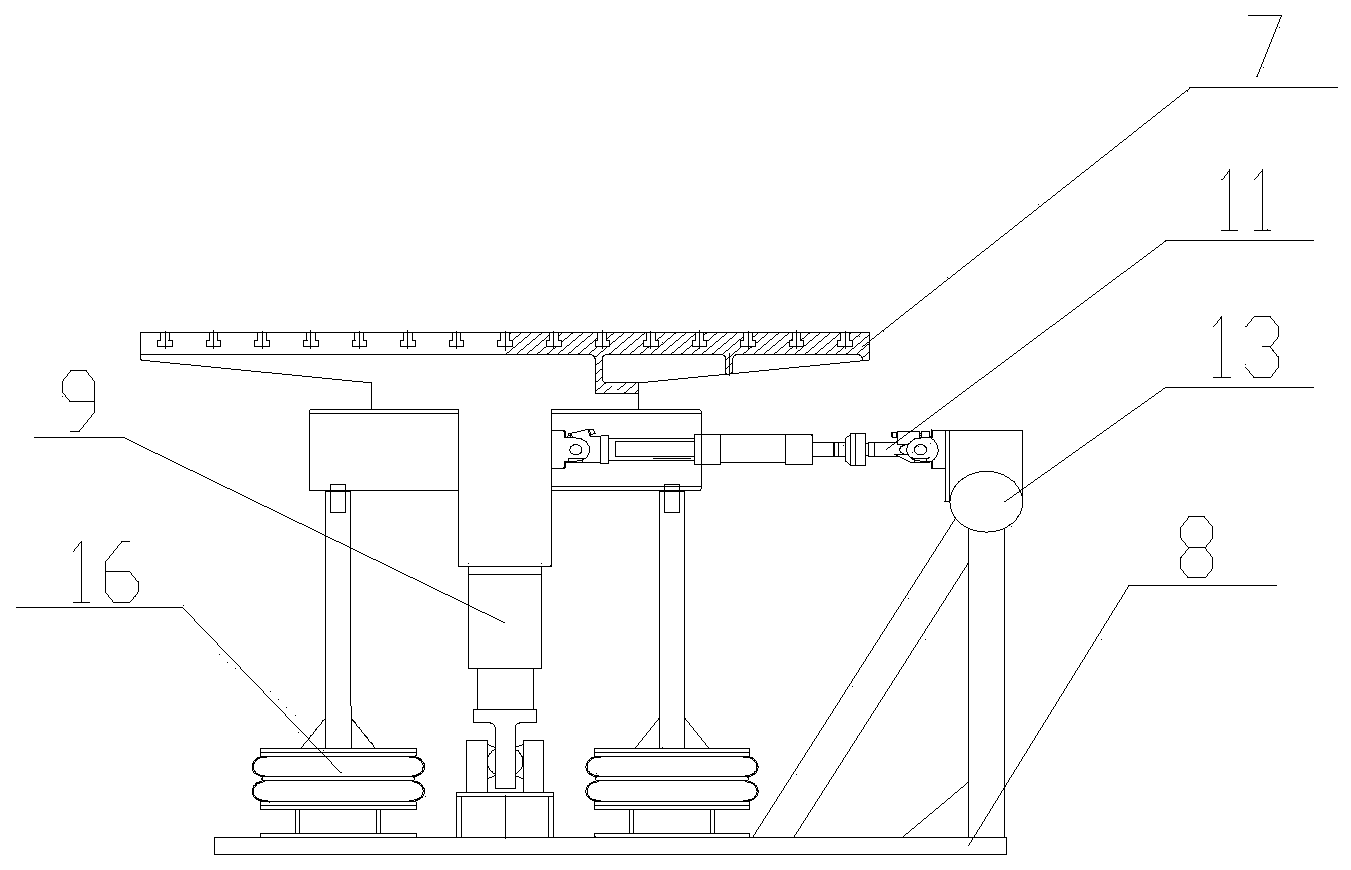

[0106] The specific implementation method is:

[0107] 1) Control the two vertical actuators 9 below the test platform 1 so that the four vertical actuators 9 below the front and rear test platforms 1 maintain the same height. Record the height difference between the left and right sides of the surface of the test platform 1, and calculate the angle δ formed by the test platform 1 in the left and right direction. Measure the angle η formed by the hanging plumb line above the surface of the end of Train 2 and the location marked in Step C.

[0108] 2) Control the two vertical actuators 9 below the front end test platform 1, so that one vertical actuator 9 moves upward for a certain distance, the other vertical actuator 9 keeps its position unchanged, and the rear end test platform 1 Two vertical actuators 9 below also keep the position unchanged. Record the height difference between the left and right sides of the surface of the test platform 1, and calculate the angle δ form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com