Coring shield mechanism of tunnel boring machine

A technology of roadheader and core shield, which is used in mining equipment, earth-moving drilling, tunnels, etc., and can solve problems such as high requirements, high risks, and slow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

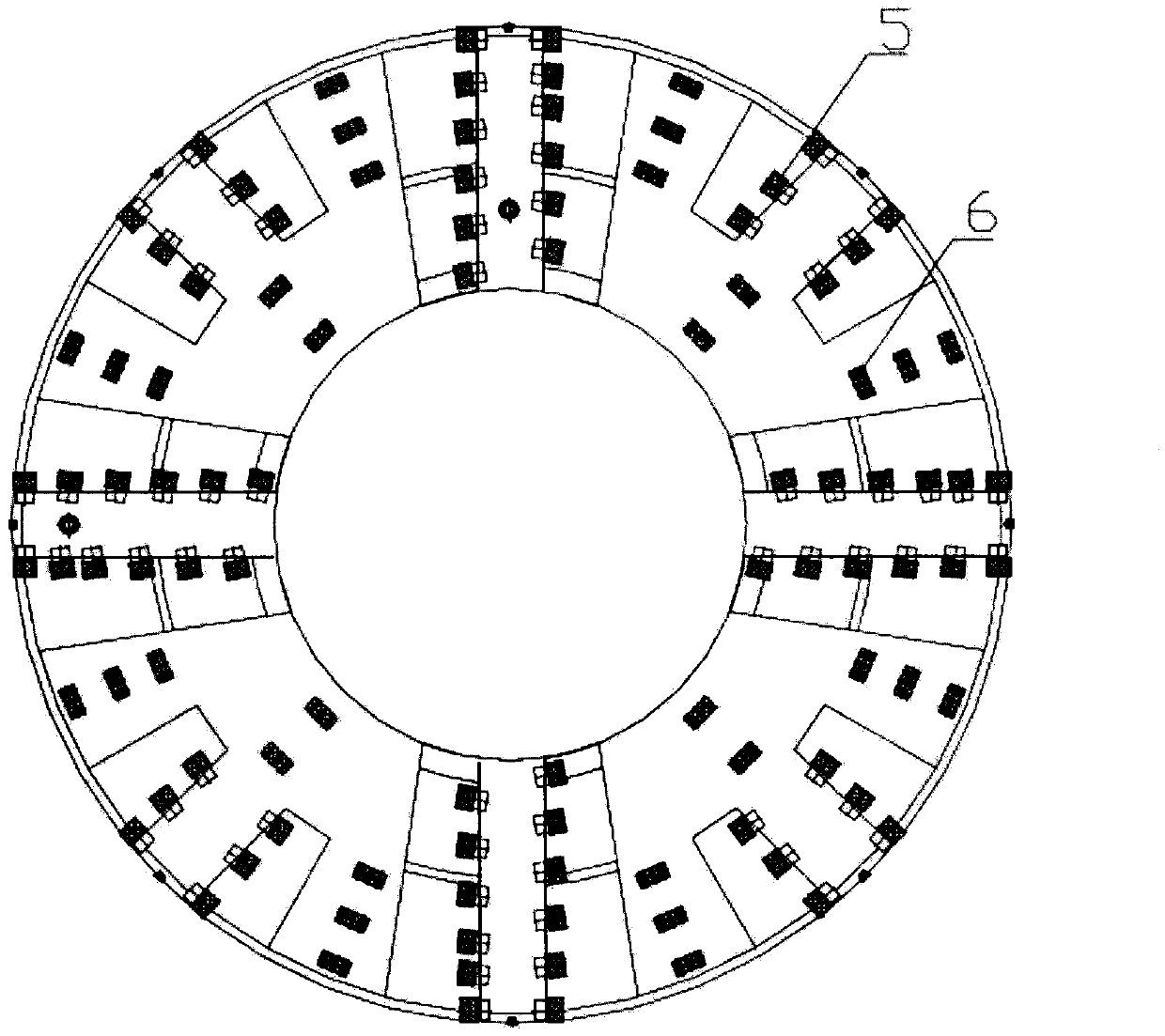

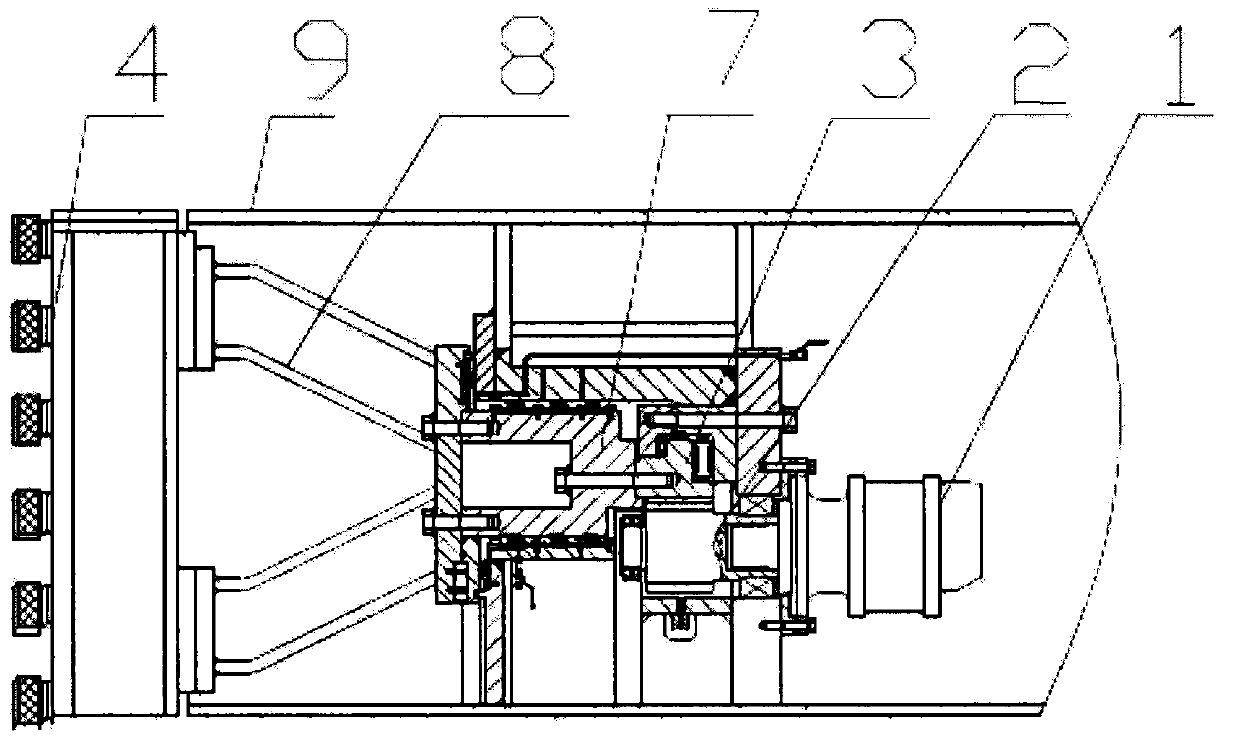

[0019] Such as figure 1 and 2 As shown, a core-taking shield mechanism of a roadheader includes a propulsion device; a conversion device, which cooperates with the propulsion device; a rotary fixed seat 7, which is arranged on one side of the conversion device to be driven, One side of the rotating fixed base 7 is further connected with a support leg 8 , and one end of the support leg 8 is connected with the cutter head 4 .

[0020] Wherein, the propulsion device is a hydraulic motor 1, as a power device, the propulsion rod of the hydraulic motor 1 is ejected in due course according to the setting during work, so as to touch the gear 1 2 to realize the rotation of the gear 1 2; the conversion device includes the gear 1 2 and The gear two 3 that meshes with the gear one 2; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com