Cast-in-place beam support truss integral dropping and dismounting tool and construction method thereof

A technology for supporting trusses and cast-in-place beams, which is used in building maintenance, construction, building construction, etc., can solve the problems of low demolition efficiency of demolition equipment, save cranes and labor costs, improve demolition efficiency, and shorten the speed of demolding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

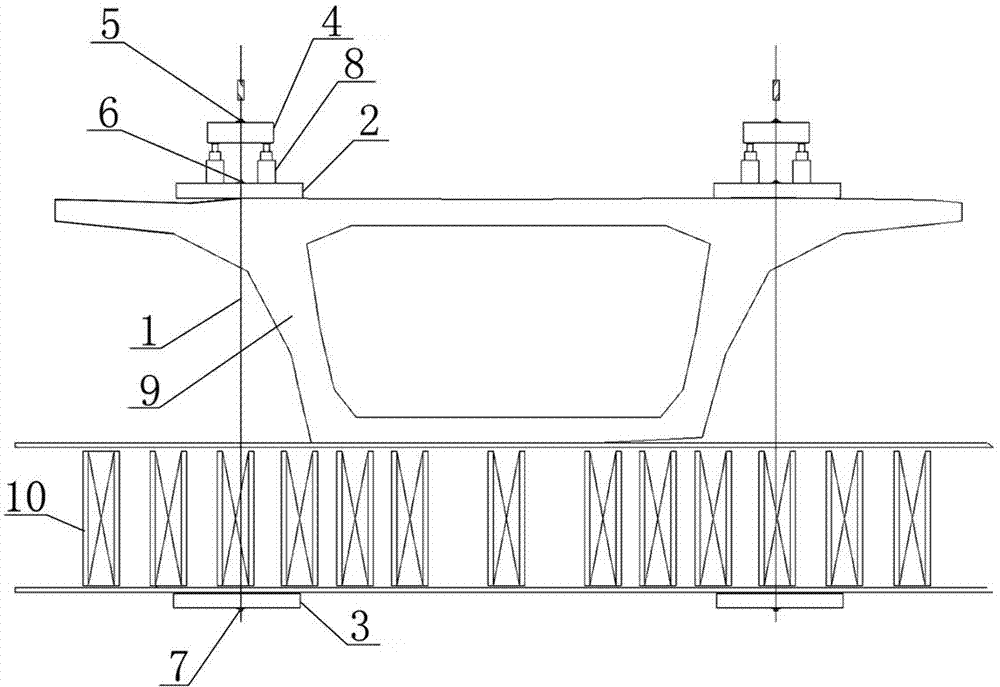

[0026] Examples see figure 1 As shown, the cast-in-place beam supporting truss is lowered and dismantled as a whole, including four sets of dismantling tools installed on both sides of the upper part of the box girder 9, and the girder body supporting truss 10 is hoisted below the box girder 9 by four sets of dismantling tools.

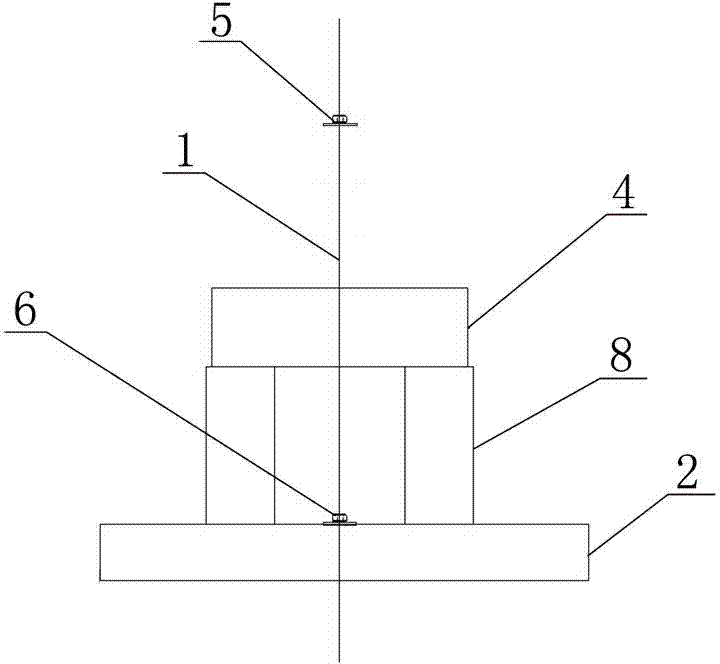

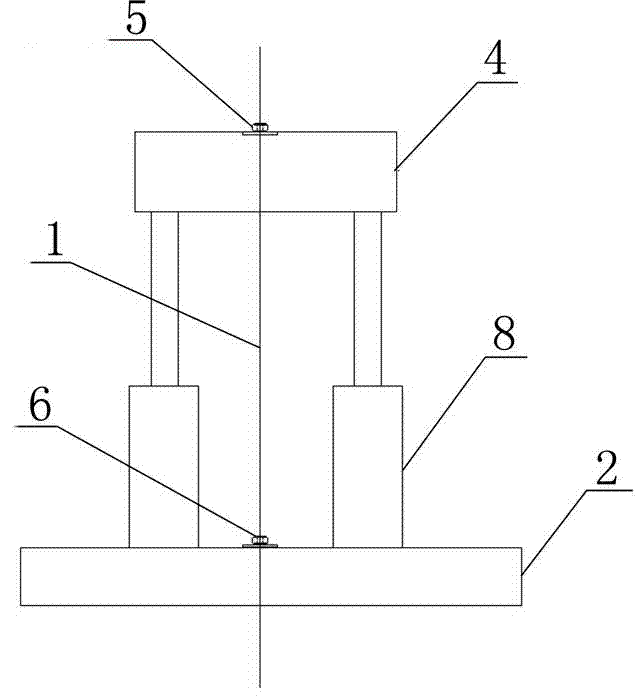

[0027] Described demolition frock comprises suspender 1, last pad pillow 2, bottom pad pillow 3, shoulder pole beam 4, upper fixing bolt I5, upper fixing bolt II6, lower fixing bolt 7 and two jacks 8. The upper cushion 2 is located on the box girder 9, two jacks 8 are placed on the upper cushion 2, the oil cylinder of the jack 8 tops the shoulder beam 4, and the lower cushion 3 is placed on the bottom surface of the beam support truss 10. The suspender 1 is made of finish-rolled rebar. The upper end of the suspender 1 passes through the reserved hole on the box girder 9, the upper cushion 2 and the pole beam 4 successively. The upper fixing bolt I5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com